Magnet used for high-frequency welding device, high-frequency welding device and automatic peeling welding machine

A high-frequency welding and welding machine technology, applied in high-frequency current welding equipment, welding equipment, connections, etc., can solve problems such as high-frequency welding devices that cannot be applied to automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

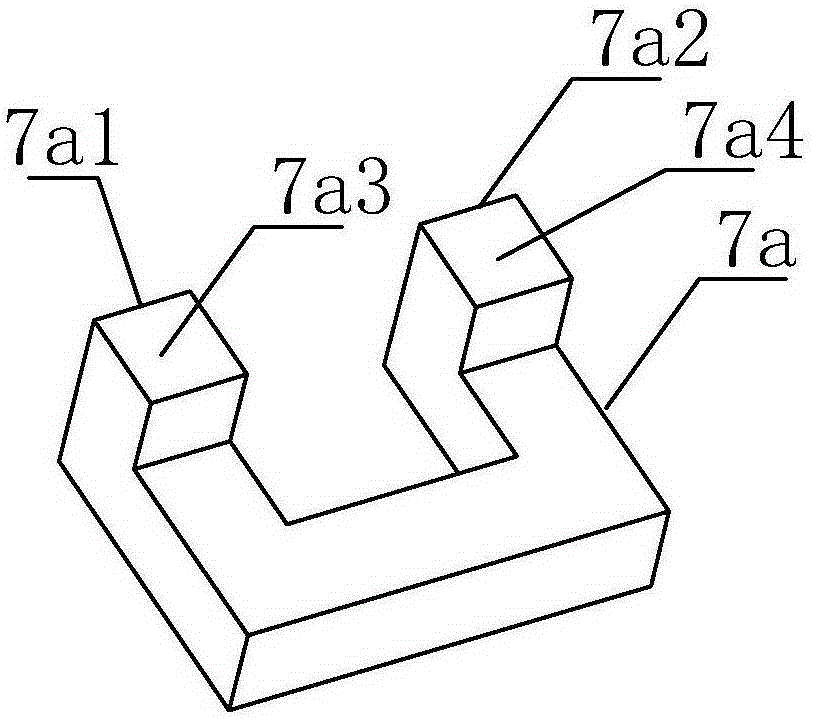

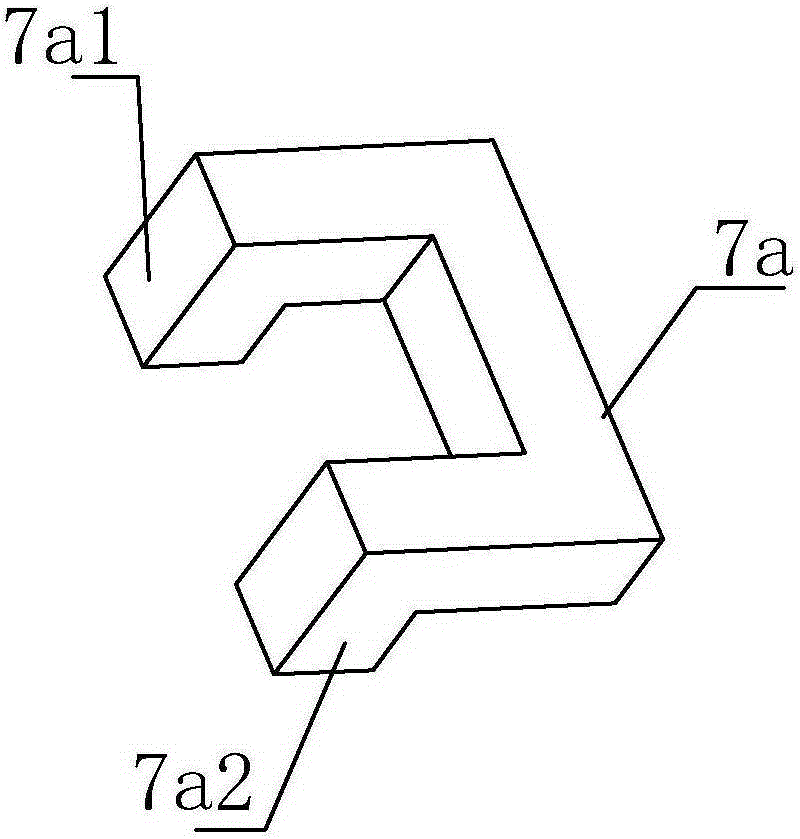

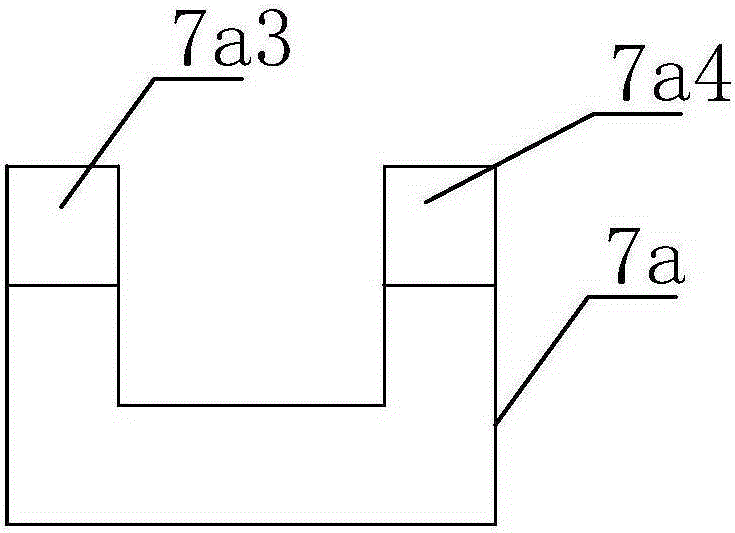

[0067] Such as Figure 1 to Figure 6 As shown, a magnet for a high-frequency welding device according to the present invention has a U-shaped magnet 7a, and bosses 46a and 46a are symmetrically extended on the same side of both ends.

[0068] The bosses 7a1, 7a2 have extended and diverted end faces 7a3, 7a4.

[0069] The end faces 7a3, 7a4 are attached and connected with upper and lower magnetic welding heads 7b, 7c which can move up and down relative to each other. The sides of the upper and lower magnetic welding heads 7b, 7c are in contact with the end faces 7a3, 7a4, and the upper and lower relative ends form a contact welding gap.

[0070] Such as Figure 34 to Figure 38 As shown, a high-frequency welding device includes a horizontal guide rail 1ab for guiding wire ends and a welding device 7 arranged on the opposite side of the horizontal guide rail 1ab. The welding device 7 includes a magnet 7a, an upper and lower magnet welding head 7b , 7c, welding head driving cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com