Pressure foot unit of automatic drilling and riveting machine

An automatic drilling riveting machine and presser foot technology, applied in the field of machining, can solve the problems of riveting work influence, riveting parts cannot be pretreated, presser foot design can not control component reinforcement well, etc., to improve production efficiency and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

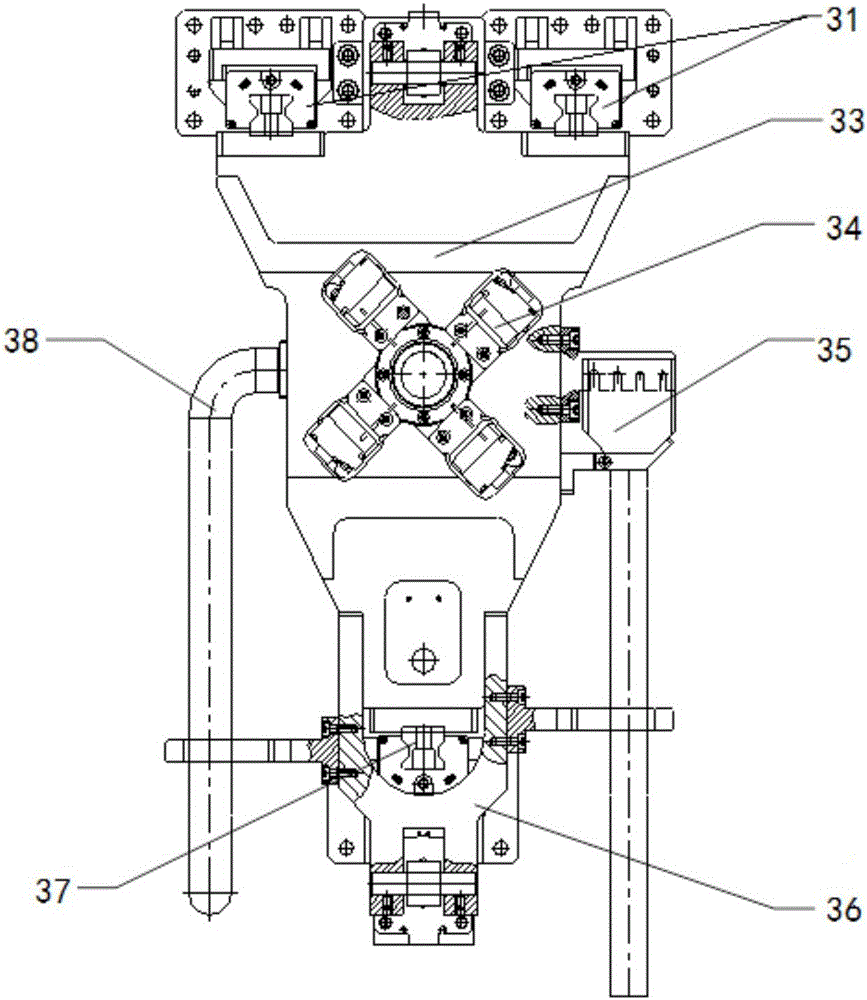

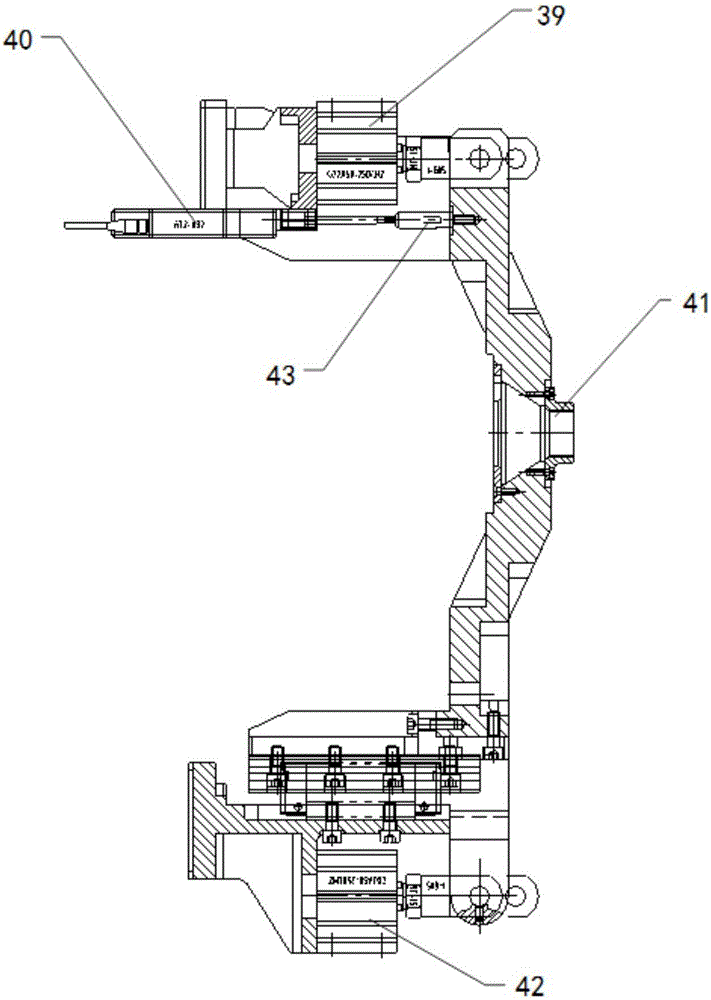

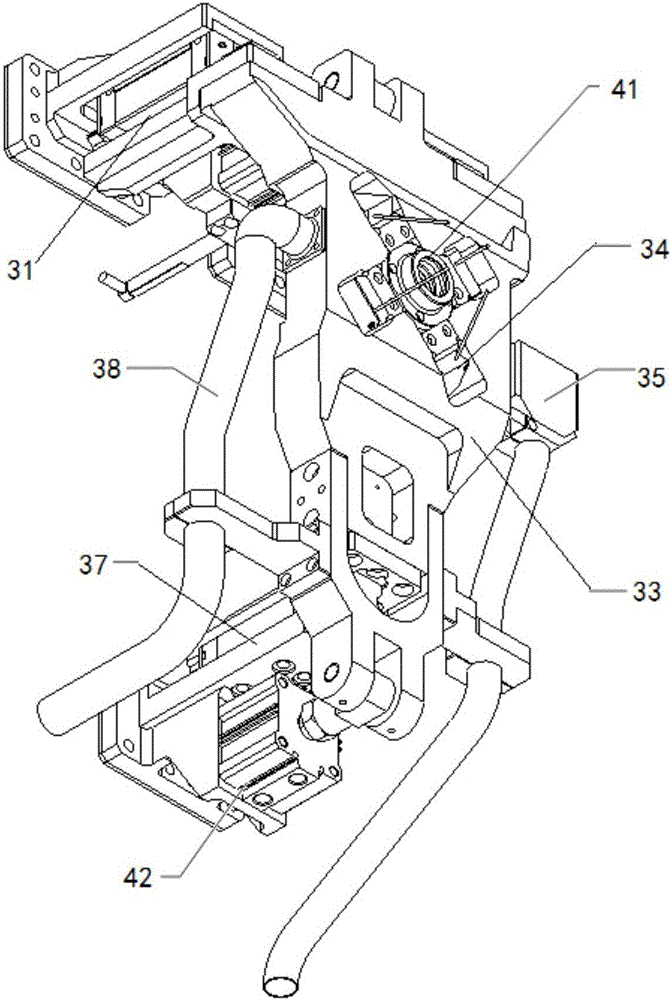

[0043] like Figure 1 ~ Figure 3 As shown, a presser foot unit of an automatic drilling and riveting machine passes through an upper guide rail 31, a presser foot body 33, a laser ranging sensor 34, a recovery assembly 35, a transition joint 36 under the presser foot, a lower guide rail 37, a chip removal pipe 38, an upper Driving cylinder 39, length gauge 40, presser foot head 41, lower driving cylinder 42 etc. are assembled. The entire presser foot unit is connected with the automatic drilling and riveting machine through the slider seat of the upper and lower guide rails. The presser foot main body 33 is connected with the upper guide rail 31 guide rail seat, and the upper driving cylinder 39 is installed on the upper guide rail slider base and is connected with the presser foot main body 33 by pins. The length gauge 40 is installed on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com