Method and system for forming blind gongs on printed circuit board (PCB) and circuit board

A technology for printed circuit boards and blind gongs, which is applied in manufacturing tools, printed circuits, printed circuit manufacturing, etc., can solve the problem of affecting the accuracy of blind gong processing, difficult to control the depth of blind gongs, and easy warping of auxiliary platform bakelite boards. problems, to achieve the effect of avoiding low precision and accurately controlling the depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

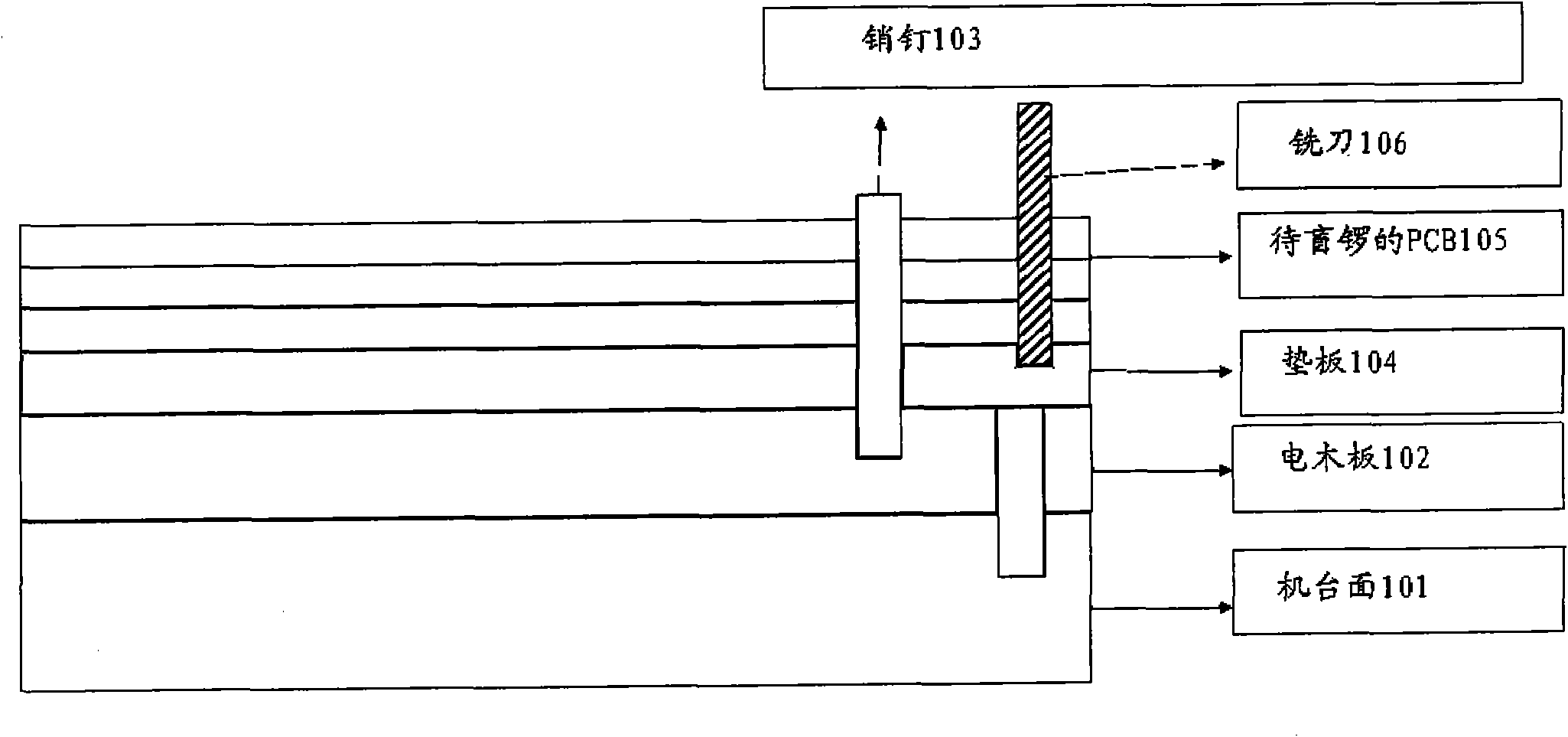

[0022] In the embodiment of the present invention, when the blind gong is processed on the PCB, the PCB to be blind gong is directly fixed on the machine table of the blind gong forming machine, thus avoiding the low processing precision caused by the auxiliary platform bakelite The problem.

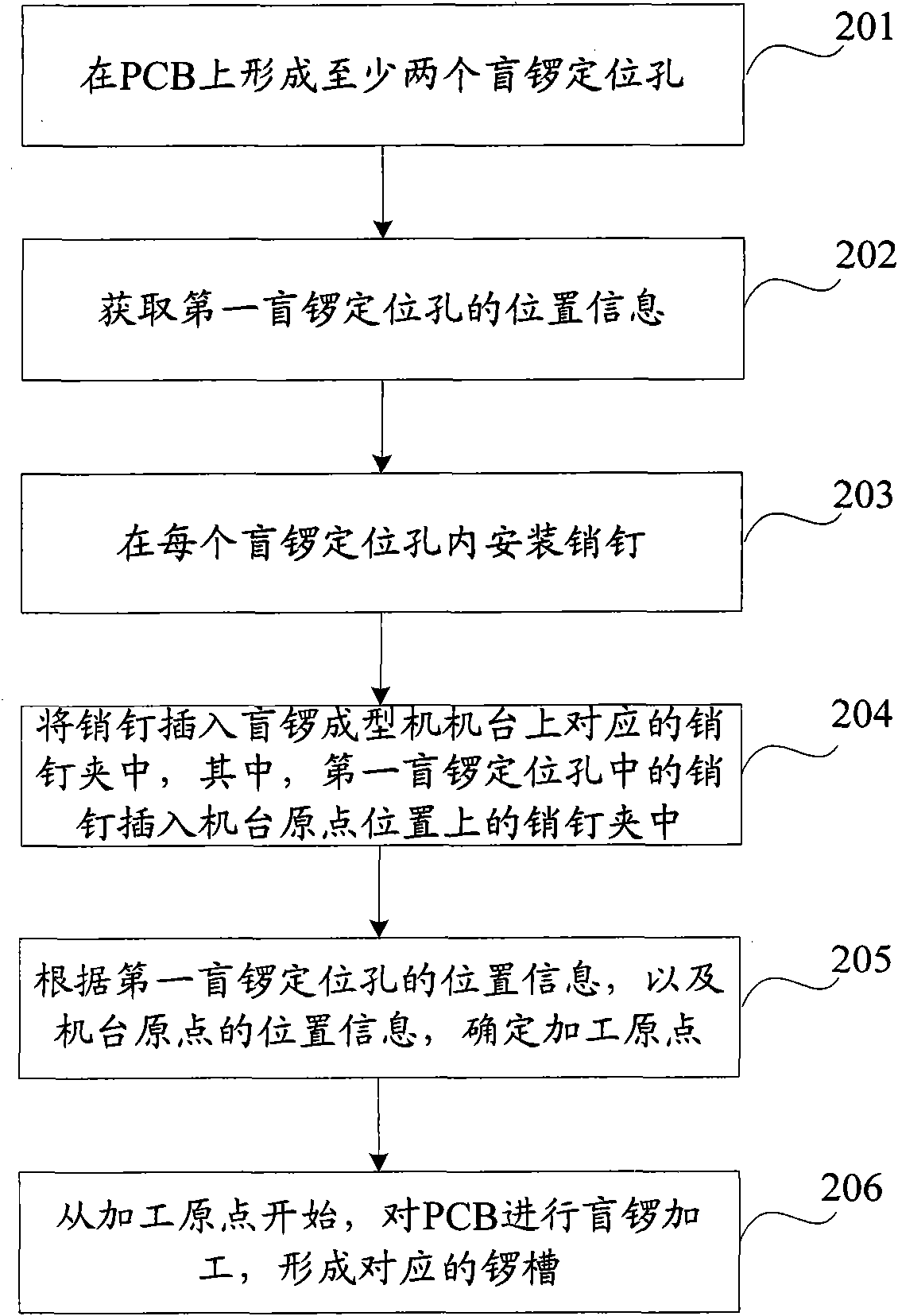

[0023] see figure 2 , in the embodiment of the present invention, the process of PCB molding blind gong processing includes:

[0024] Step 201: Form at least two blind gong positioning holes on the PCB.

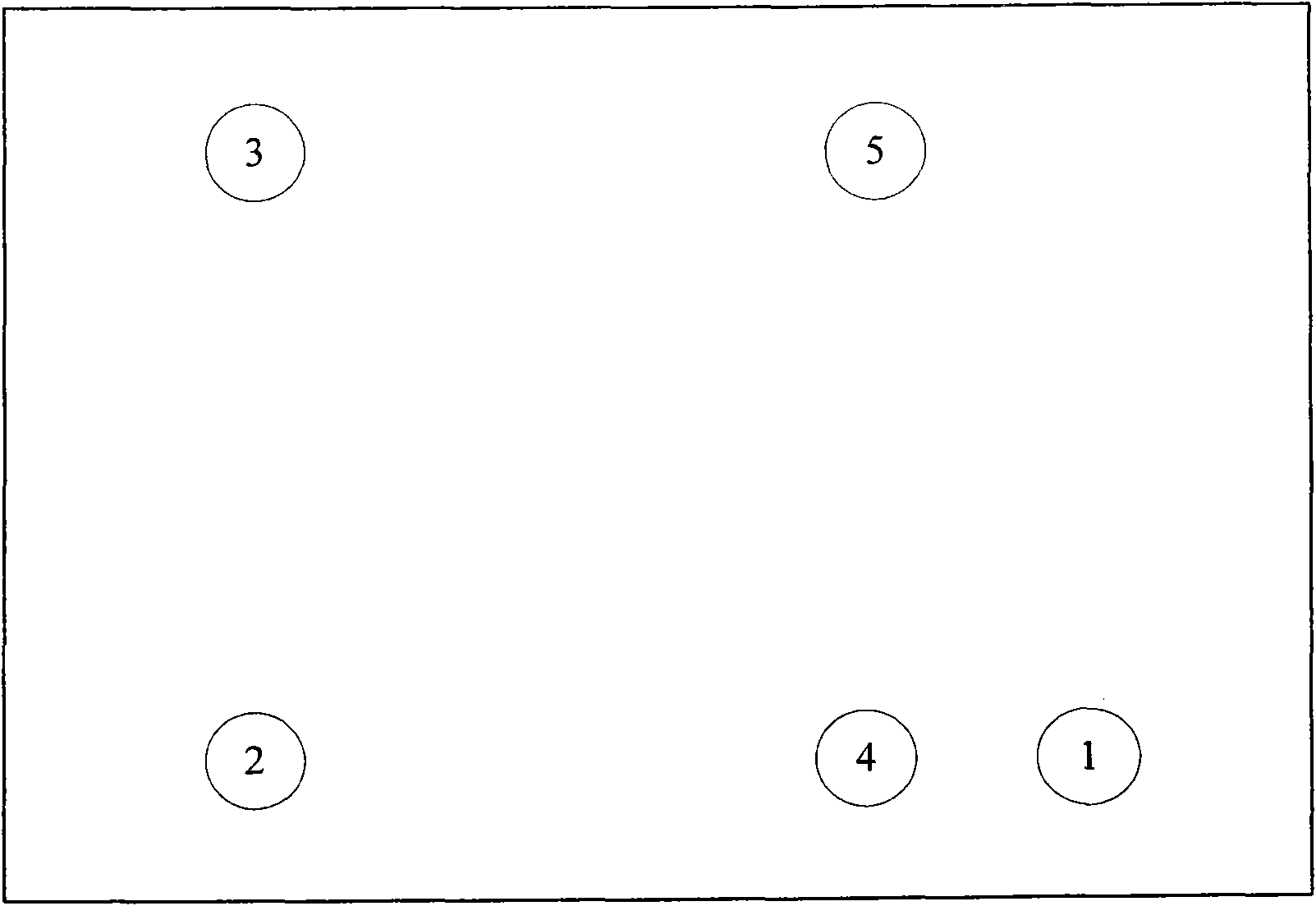

[0025] In order to fix the PCB to the machine table of the blind gong molding machine, generally at least two blind gong positioning holes are required. Two or more blind gong positioning holes can be formed in free positions on the PCB. Of course, in order not to affect the positioning holes required by other processes, preferably, at least two blind gong positioning holes are formed on the set positions of the PCB. Generally, two or more blind gong positioning holes can be formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com