Multi-welding-head ultrasonic welding machine

A technology of ultrasonic welding and multiple welding heads, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low precision, low welding quality, large gap, etc., to reduce vibration, simple structure, and easy to use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

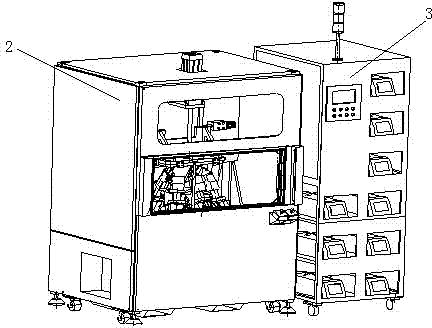

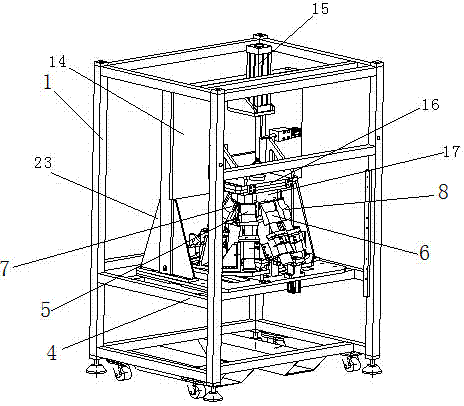

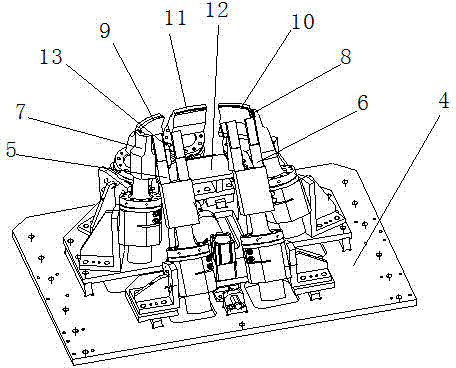

[0017] Such as Figure 1 to Figure 4 As shown, a multi-welding head ultrasonic welding machine includes a frame 1, an outer cover 2 is provided on the outside of the frame 1 and an electrical control cabinet 3 is connected, and the welding unit set in the frame 1 is a multi-welding head welding group and a driving workpiece The workpiece positioning device for press welding, the multi-welding head welding group is arranged in a ring on the base connecting plate 4, the multi-welding head welding group is composed of 7 sets of welding units, and further includes the left front welding head 5, the right front welding head 6, the left side Welding head 7, right side welding head 8, rear left side welding head 9, rear right side welding head 10 and rear middle welding head 11, two workpiece cooling air outlets 13 are set on the middle seat 12 surrounded by the welding unit , the welding points of the left side welding head 7, the right side welding head 8, the rear left side weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com