Production method of semiconductor device

A device manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing corrosion rate, increasing defects, prolonging corrosion time, etc., to reduce roughness, reduce Defects, the effect of improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

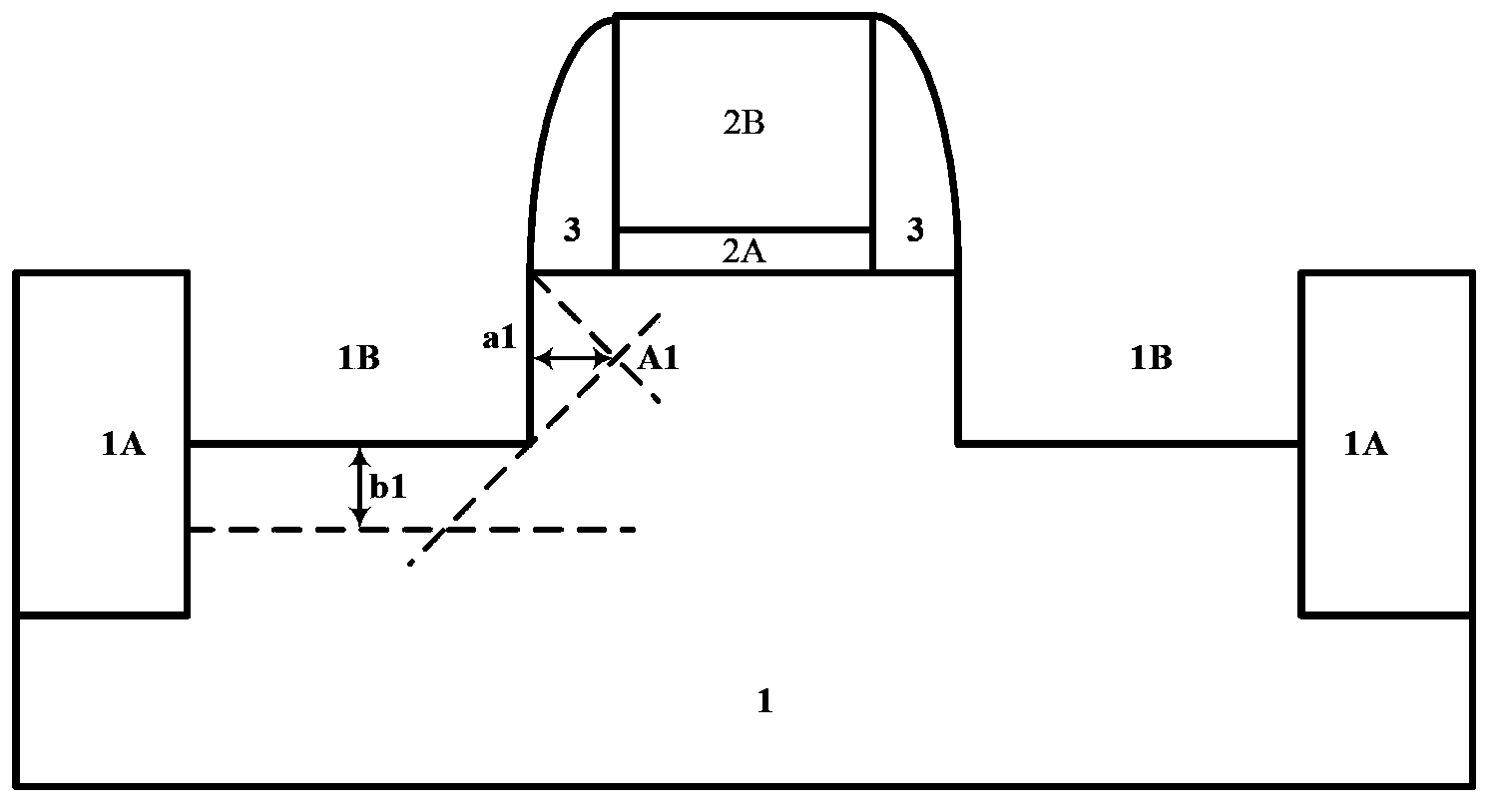

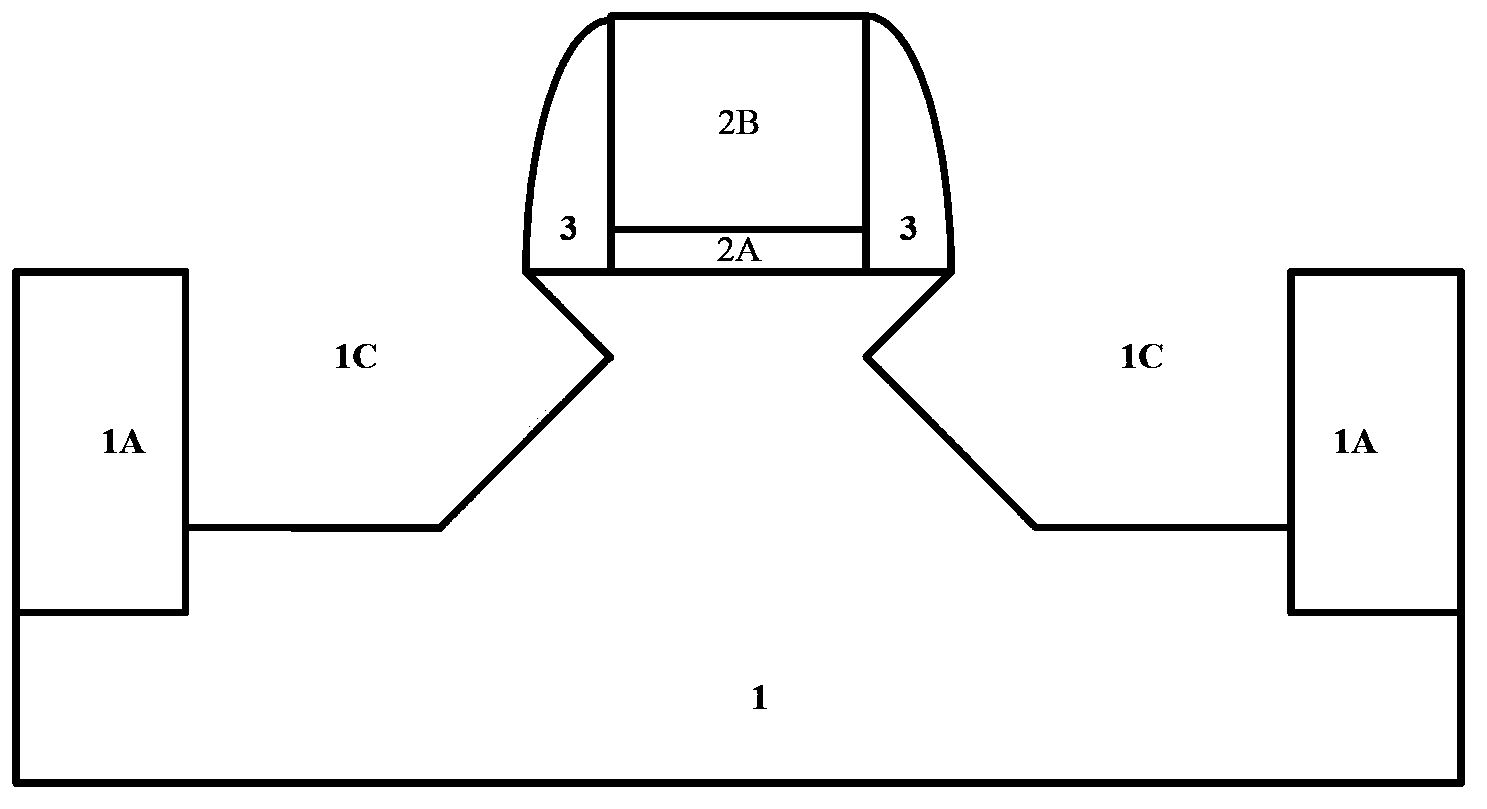

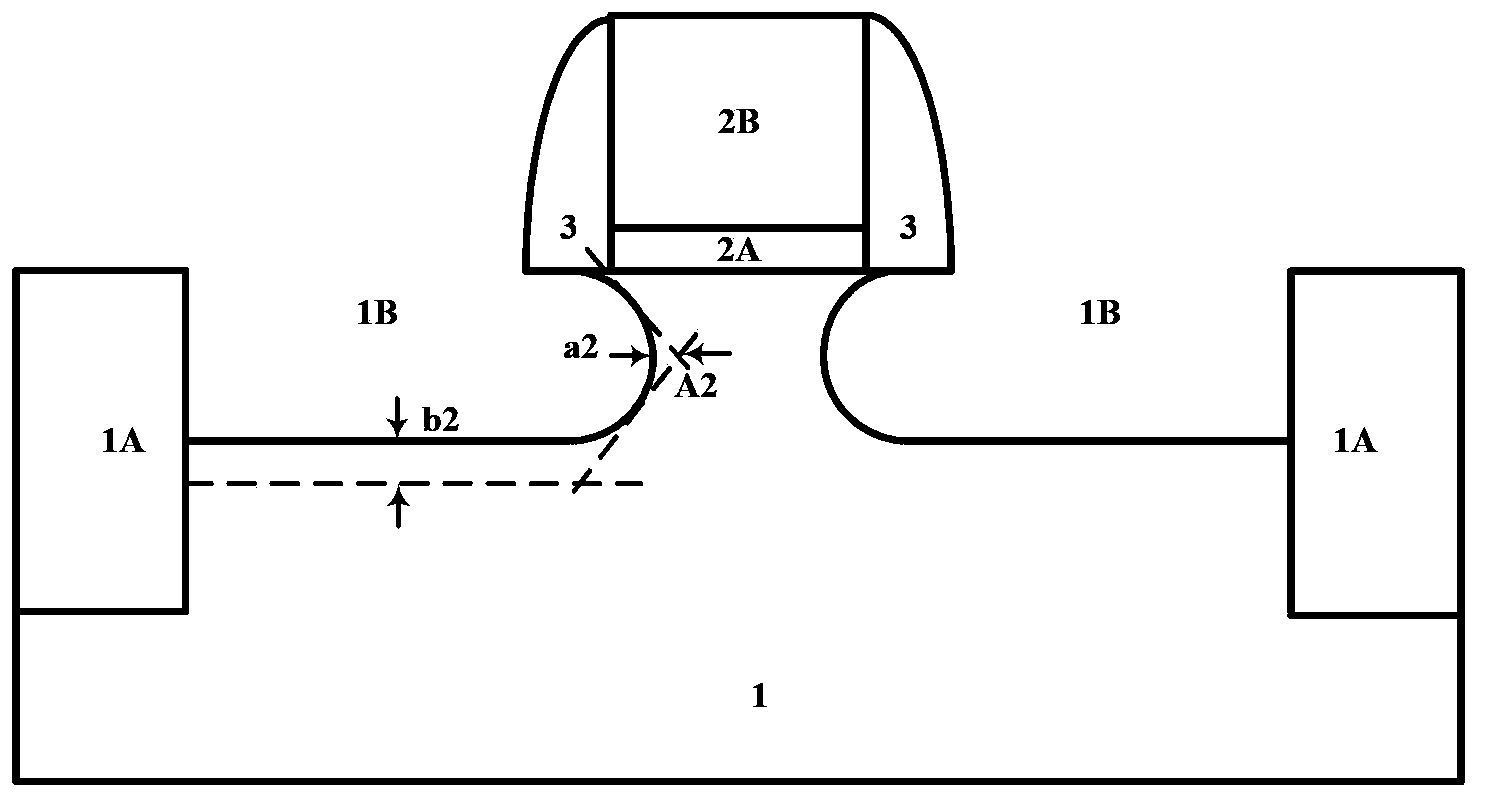

[0024] The features and technical effects of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the schematic embodiments. It should be noted that similar reference numerals denote similar structures, and the terms "first", "second", "upper", "lower", "thick", "thin", etc. used in this application may be used for Trim various device structures. These modifications do not imply a spatial, sequential, or hierarchical relationship of the modified device structures unless specifically stated.

[0025] refer to Figure 5 as well as image 3 , dry etching the substrate to form C-type source and drain grooves.

[0026] Provide a substrate 1, provide a substrate 1, which can be bulk Si, SOI, bulk Ge, GeOl, SiGe, GeSb, or a III-V or II-VI compound semiconductor substrate, such as GaAs, GaN, InP , InSb, etc. In order to be compatible with the existing CMOS process for application in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com