Flexible grinding device for soft and brittle materials

A kind of grinding device and flexible technology, applied in the direction of grinding device, grinding/polishing safety device, grinding machine tool, etc., can solve the problems of surface crack propagation, prone to chipping, residue on the surface of the workpiece, etc., to improve the surface quality of the workpiece, good quality Elasticity and ductility, the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

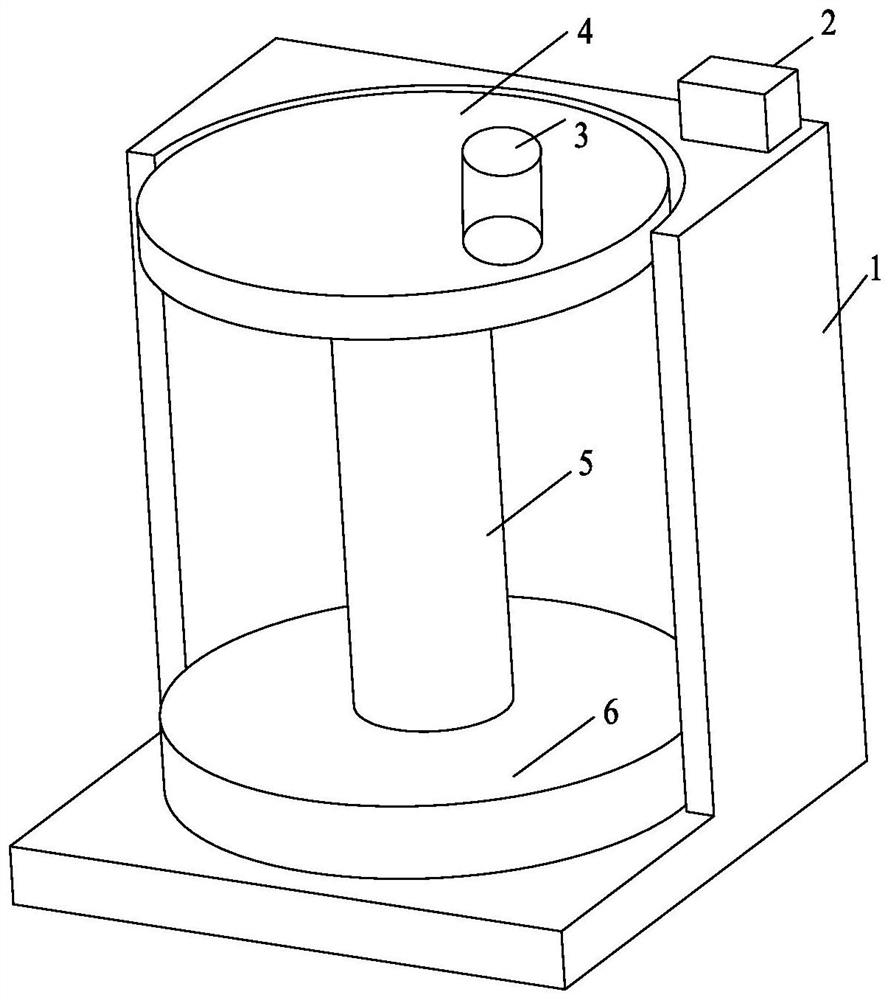

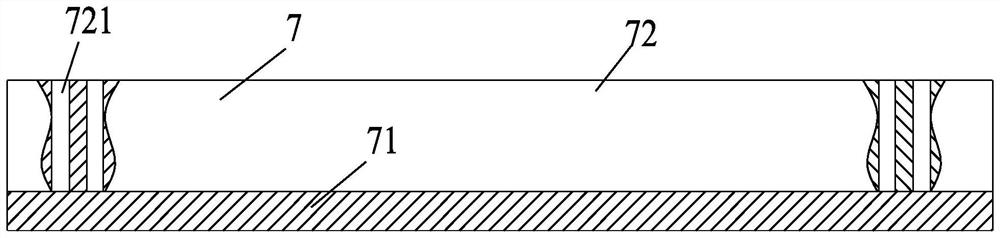

[0029] refer to Figure 1~4 , this embodiment provides a flexible grinding device for soft and brittle materials, including a housing 1, a grinding disc 4 and a workpiece fixing device 3; the housing 1 is placed horizontally to support the entire device; the grinding disc 4 is provided with Grinding pad 7, described grinding disc 4 and grinding pad 7 rotate under the effect of driving device, specifically, described driving device comprises transmission shaft 5 and driving motor 6, and described driving motor 6 is connected with driving shaft 5, and transmission The shaft 5 is fixedly connected to the grinding disc 4, and the driving motor 6 drives the transmission shaft 5 to rotate, thereby driving the grinding disc 4 to rotate; the workpiece fixing device 3 is arranged above the grinding disc 4, and is used to clamp the workpiece to be ground and make it radially vibration, the workpiece to be ground can be rotated under the drive of the workpiece fixture 3; the lower end of...

Embodiment 2

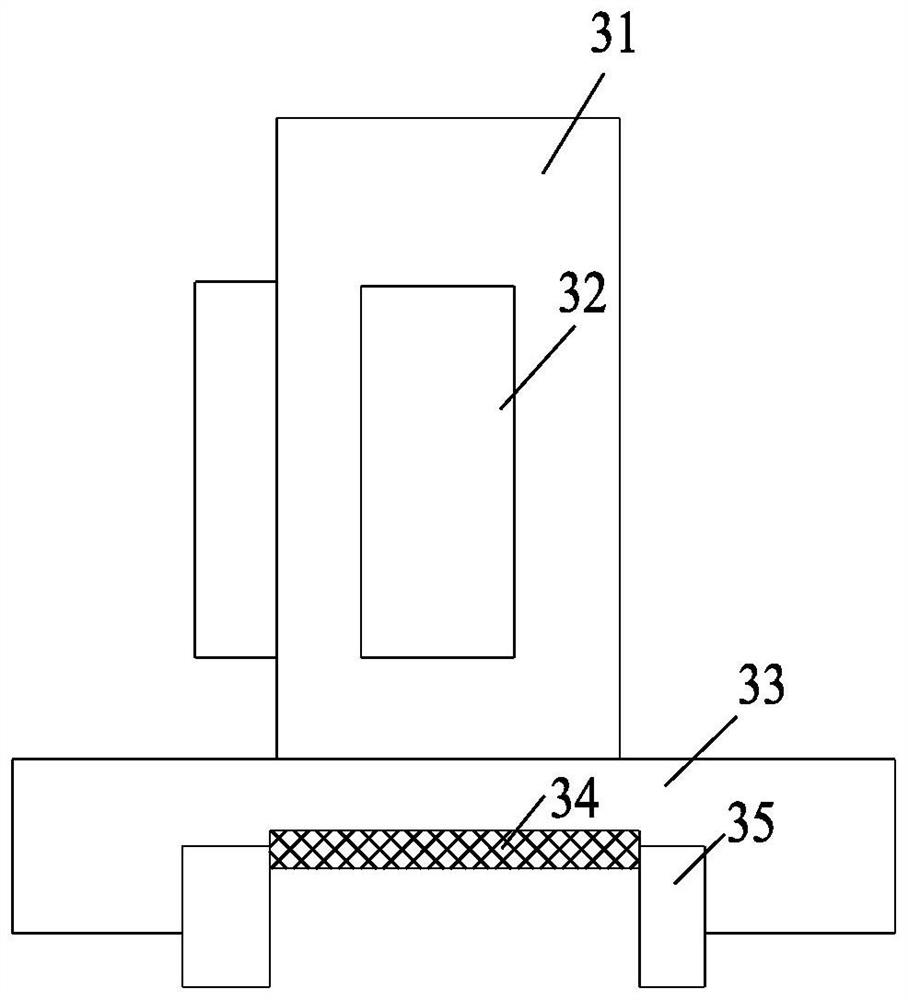

[0037] An embodiment of the present invention provides a flexible grinding device for soft and brittle materials. The structure of this embodiment is substantially the same as that of Embodiment 1, except that this embodiment limits the specific structure of the clamping mechanism.

[0038] refer to Figure 5 As mentioned above, in the embodiment of the present invention, the clamping mechanism 35 includes a first transmission rod 351 (one end is provided with embossing), a first bevel gear 352, a second bevel gear 353, a second transmission rod 354, and an adapter seat 355 and jaw 356; the first transmission rod 351 is horizontally arranged, fixedly connected with the first bevel gear 352, and the second bevel gear 353 meshes with the first bevel gear 352 (the number of teeth of the first bevel gear 352 is greater than that of the second bevel gear 353 teeth), the second bevel gear 353 is in transmission connection with the first bevel gear 352; the upper end of the second tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com