Bearing pretightening force adjusting device, electric spindle and machine tool

A technology of bearing preload and adjustment device, applied in metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of strict sealing requirements, complex structure, and inability to realize real-time bearing preload adjustment, etc. High reliability, simple device structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

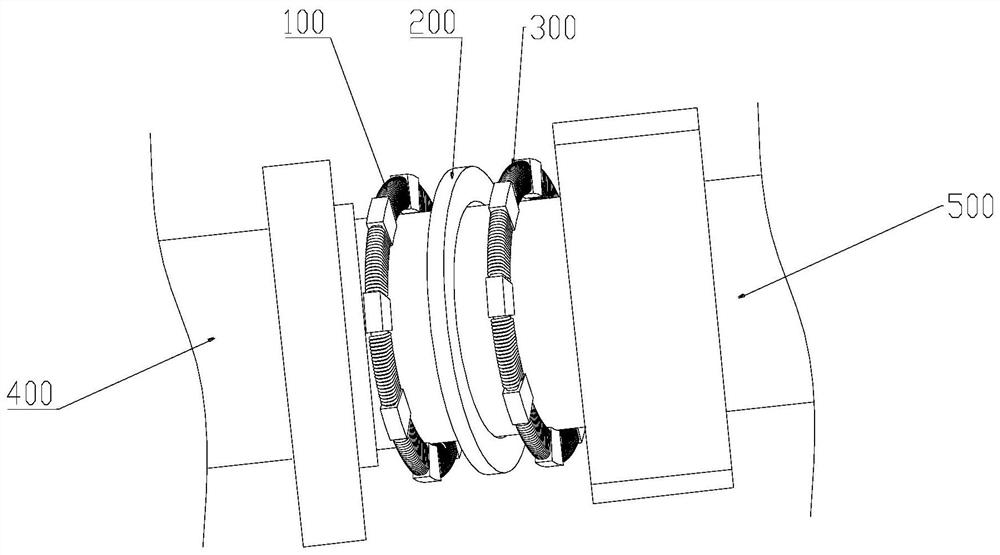

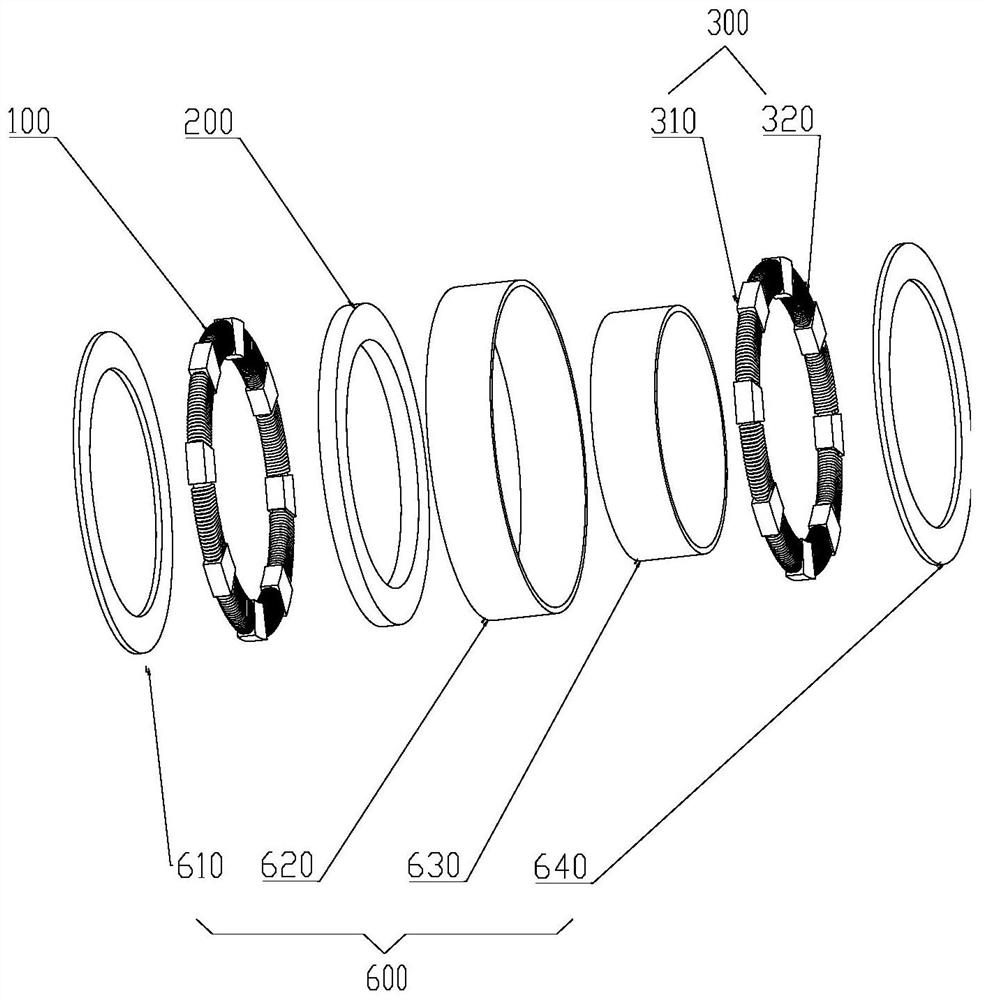

[0053] Such as Figure 1-Figure 5 As shown, a bearing pretightening force adjustment device includes: a driving power supply, a first electromagnetic coil 100 sleeved on a shaft body 400, a magnetostrictive element 200 and a second electromagnetic coil 300, and the magnetostrictive element 200 is located at Between the first electromagnetic coil 100 and the second electromagnetic coil 300 . The accompanying drawings of this application do not show the driving power supply. The preload adjusting device is arranged on the bearing 500 side of the shaft body 400, and the first electromagnetic coil 100 and the second electromagnetic coil 300 are used to generate a magnetic field with adjustable strength. More specifically, the driving power is connected to a current regulator, and the current regulator is electrically coupled to the first electromagnetic coil 100 and the second electromagnetic coil 300 respectively. The operator adjusts the magnitude of the current flowing throug...

Embodiment 2

[0081] Such as Figure 6-7 As shown, this embodiment only describes the differences from Embodiment 1, and the rest of the technical features are the same as those of the above embodiment. Further, the magnetostrictive element 200 includes M stretchable blocks 210, where M is an integer greater than one, and where M and N are equal or different. That is, the number of the telescopic blocks 210 is the same as or different from the number of the supporting blocks on the first electromagnetic coil 100 or the second electromagnetic coil 300 . As a more optimal implementation manner, the number of the telescopic blocks 210 is the same as the number of support blocks on any electromagnetic coil. The telescopic block 210 is made of magnetorheological elastomer material, and the telescopic block 210 is fixed on the first support block 110 or the second support block 310 . Further, the first support block 110 and the second support block 310 are provided with positioning protrusions ...

Embodiment 3

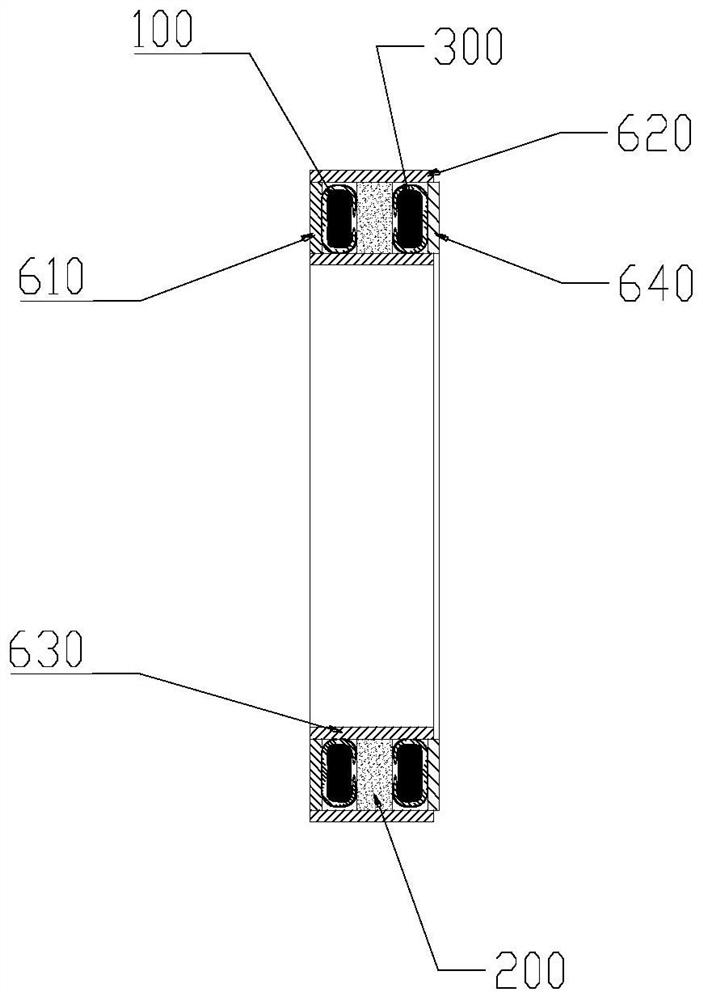

[0084] Such as Figure 6 As shown, this embodiment only describes the differences from Embodiment 1, and the rest of the technical features are the same as those of the above embodiment. Further, the magnetic isolation cover 600 includes an annular magnetic isolation main body 650 and a third cover plate 660, the magnetic isolation main body 650 is arranged on the shaft body 400, and the magnetic isolation main body 650 is provided with an annular housing Cavity 651, one side of the accommodating cavity 651 is open, and the third cover plate 660 is provided at the opening of the accommodating cavity 651;

[0085] The first electromagnetic coil 100 , the magnetostrictive element 200 and the second electromagnetic coil 300 are all disposed in the accommodating cavity 651 , and when the magnetostrictive element 200 expands and contracts axially, the third cover plate 660 Due to the expansion and contraction of the magnetostrictive element 200 , it moves along the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com