Magnetic toughening method for inhibiting machinery damage of hard and brittle materials

A hard and brittle material and toughening technology, which is applied in the quality control field of mechanical processing, can solve problems such as difficult to achieve precise control of heating process, complicated process technology, and thermal damage of workpiece, so as to improve the quality of processed surface, improve surface quality, The effect of improving grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

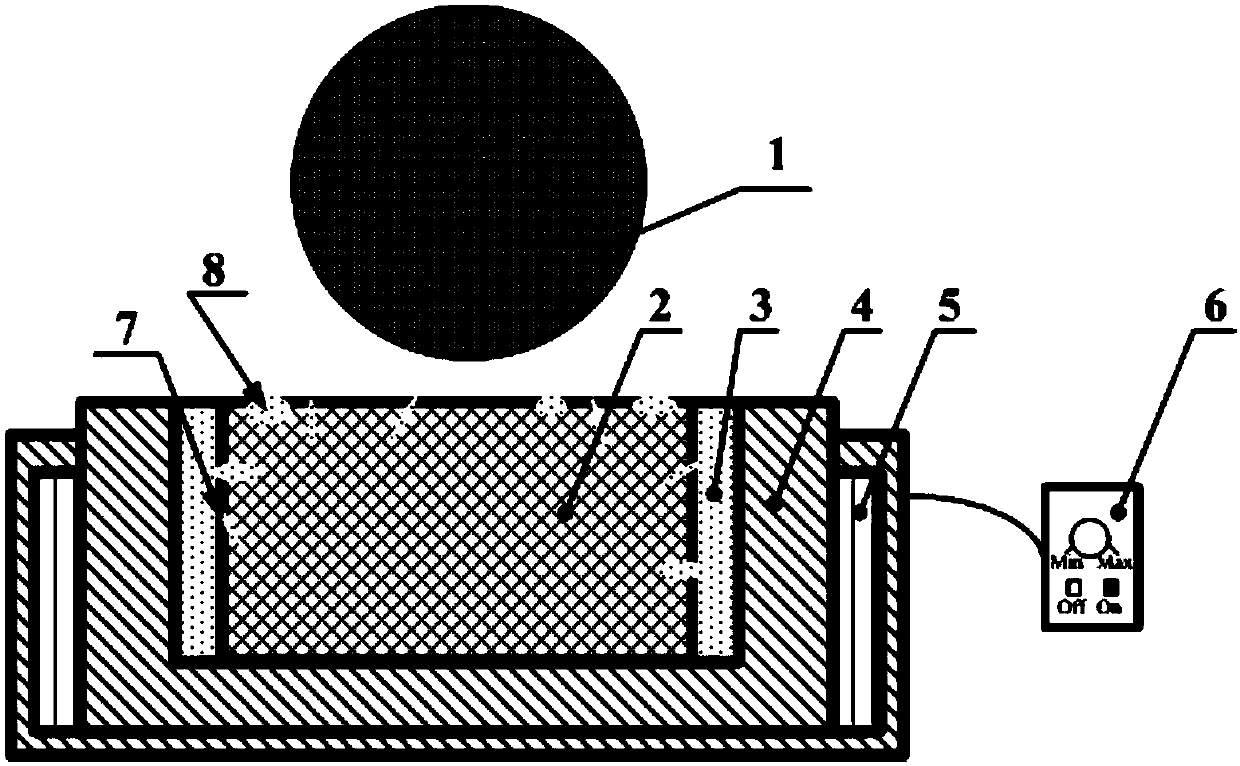

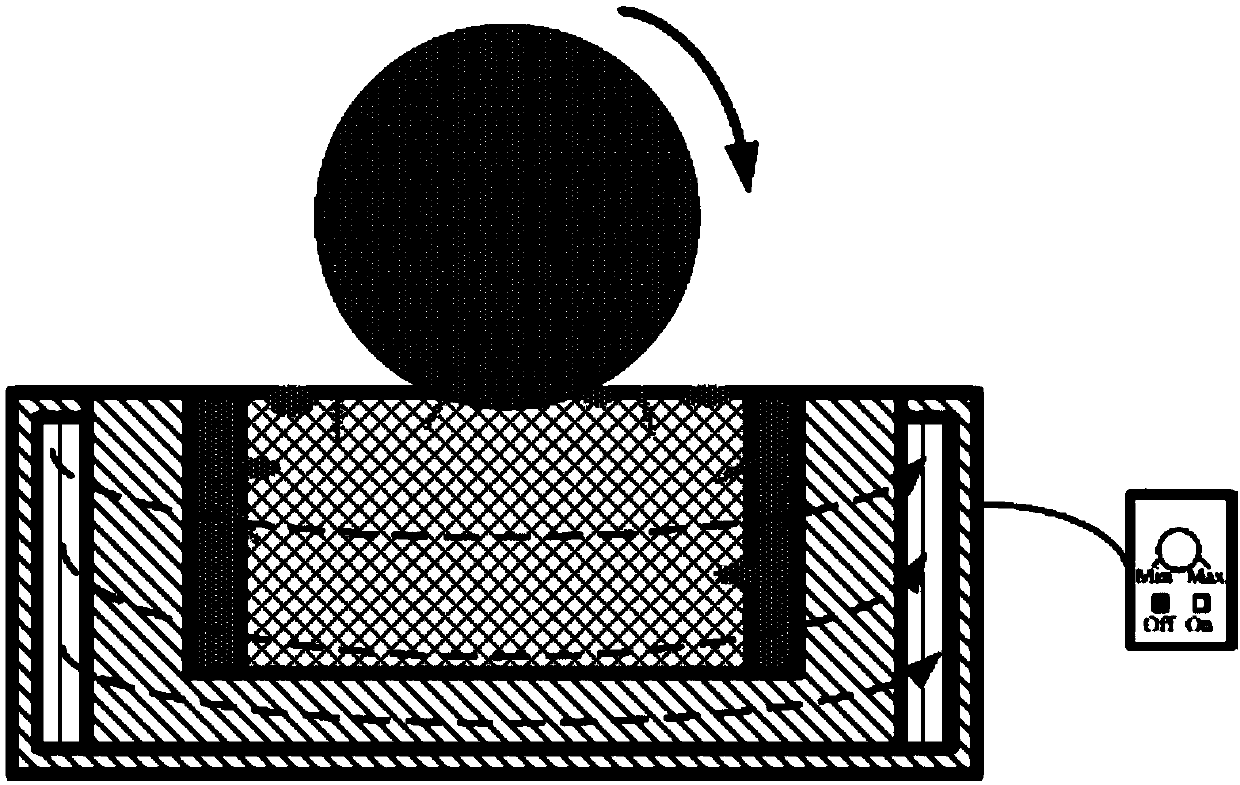

[0016] Magneto-rheological fluid produces magnetorheological effect under the action of an external magnetic field, which can realize continuous and reversible conversion between liquid and solid in an instant, and its liquid-solid phase conversion degree, viscosity and shear yield strength can be controlled by the magnetic field strength. continuous stepless change. As a research hotspot, magnetorheological fluids are currently known to be used in electronic control and mechanical fields such as automotive brakes, clutches, intelligent damping shock absorbers, magnetic polishing of hard and brittle materials, flexible fixtures, and sealing components. Magnetorheological fluid is an emerging intelligent material with great engineering application prospects, and its potential value can be continuously tapped in various fields. The present invention proposes a magnetic toughening method for the first time, cleverly utilizes the magneto-rheological effect, and achieves the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com