Processing method for grinding circular ring end surface through grinding rod with large slenderness ratio and weak rigidity

A technology with large length-to-diameter ratio and weak rigidity, which is applied in the direction of machine tools suitable for grinding workpiece planes, parts of grinding machine tools, and grinding drive devices, etc. Safety accidents, poor system stability and other problems, to achieve the effect of precise and efficient automatic grinding, easy automation, guaranteed performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

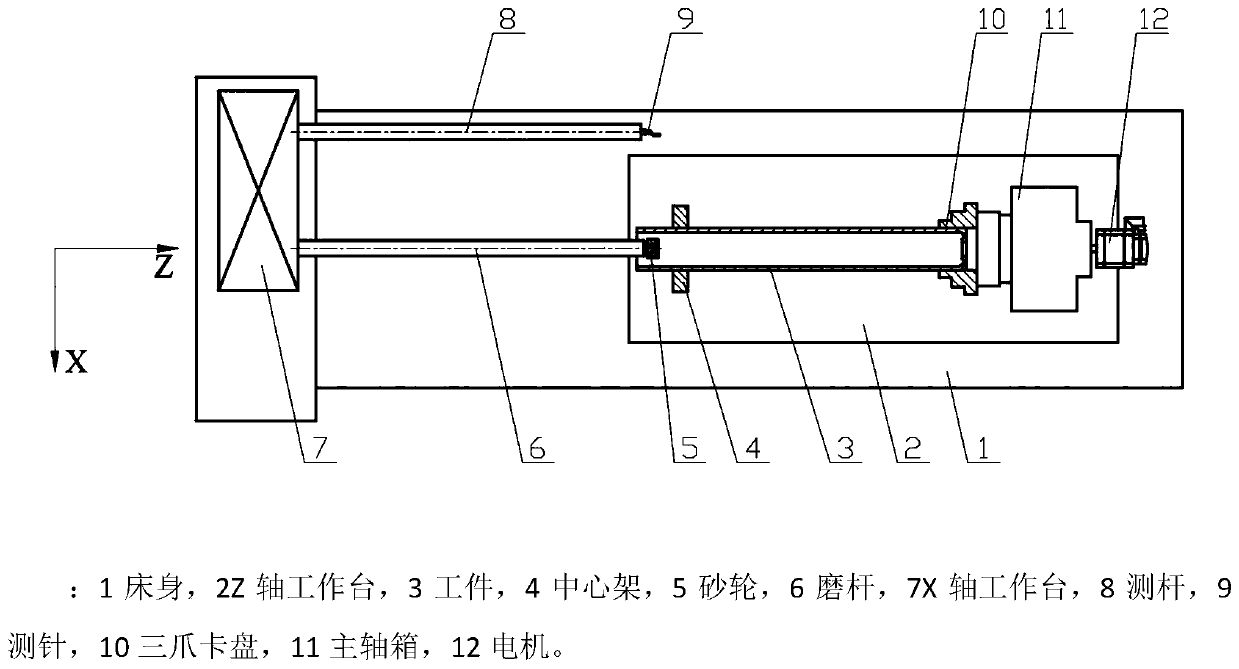

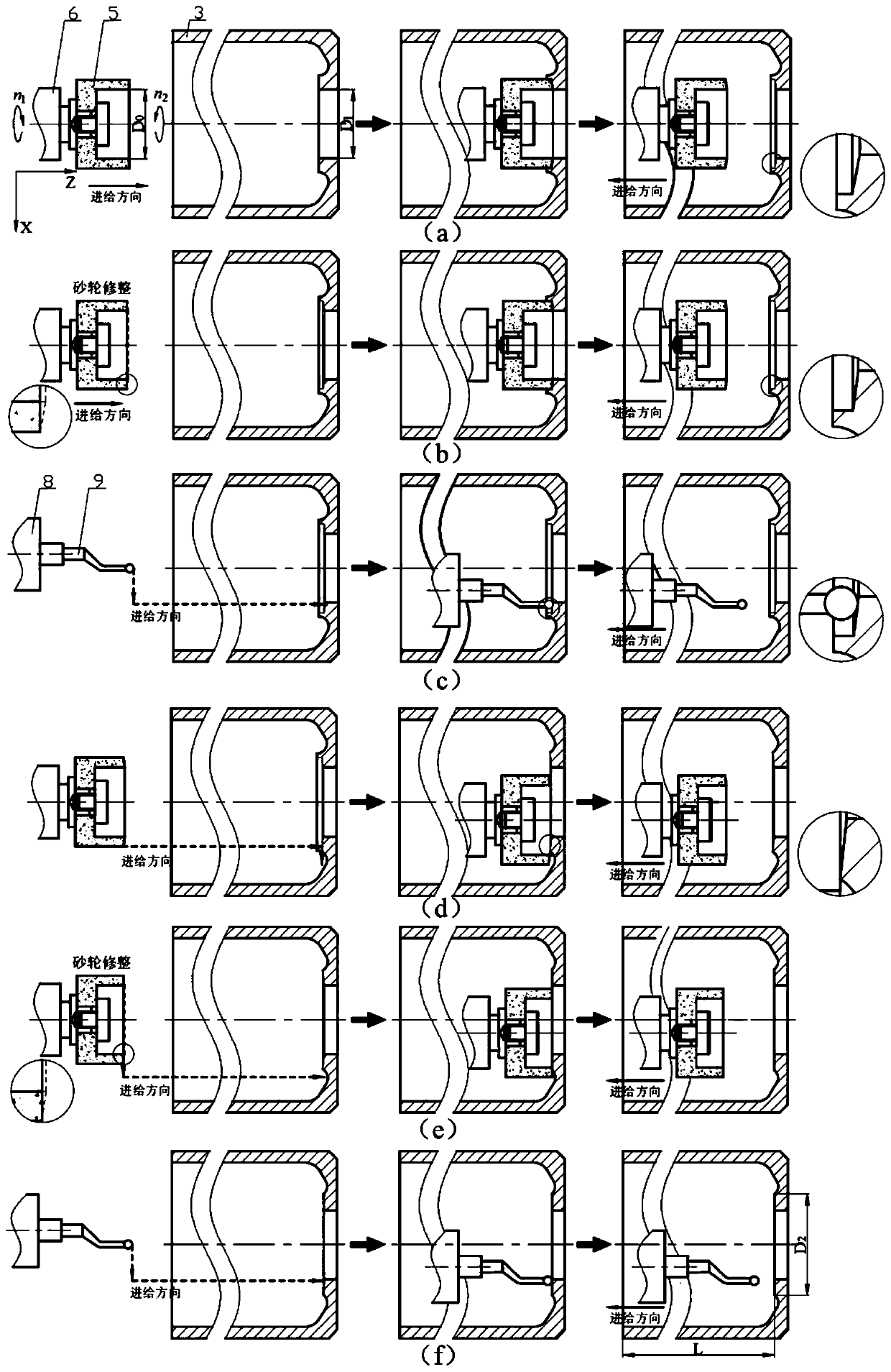

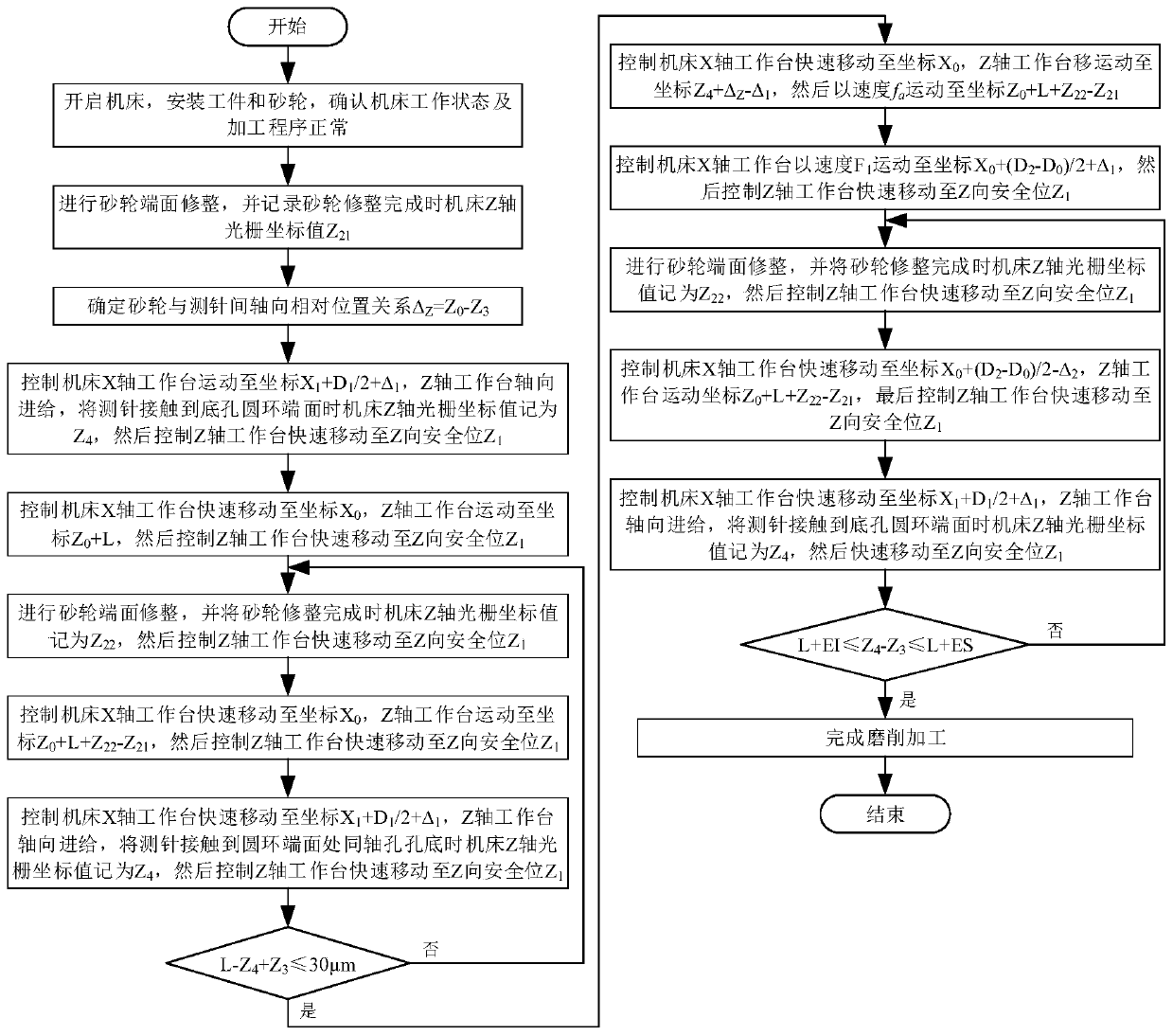

[0051] S1. Turn on the machine tool, install the workpiece 3 and the grinding wheel 5, and confirm that the working status of the machine tool and the processing program are normal.

[0052] S2. Grinding wheel dressing: control the movement of X-axis table 7 and Z-axis table 2 of the machine tool to dress the end face of the grinding wheel 5, and record the Z-axis raster coordinate value Z of the machine tool when the dressing of the grinding wheel 5 is completed 21 .

[0053] S3. Determine the axial relative positional relationship between the grinding wheel 5 and the stylus 9: control the movement of the X-axis table 7 and the Z-axis table 2 of the machine tool so that the right end surface of the grinding wheel 5 touches the left end surface of the workpiece 3, and record the Z-axis grating of the machine tool at this time Coordinate value Z 0 , and then control the X-axis table 7 and Z-axis table 2 of the machine tool to move so that the stylus 9 touches the left end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com