Structured light hand-eye calibration method based on coordinate system servo alignment

A technology of hand-eye calibration and structured light, which is applied in the field of computer vision, can solve the problems that the calibration accuracy depends on the professional level of the operator, the result consistency is poor, and the accuracy is insufficient, so as to achieve a high degree of automation, good consistency, and reduce the dependence on the technical level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

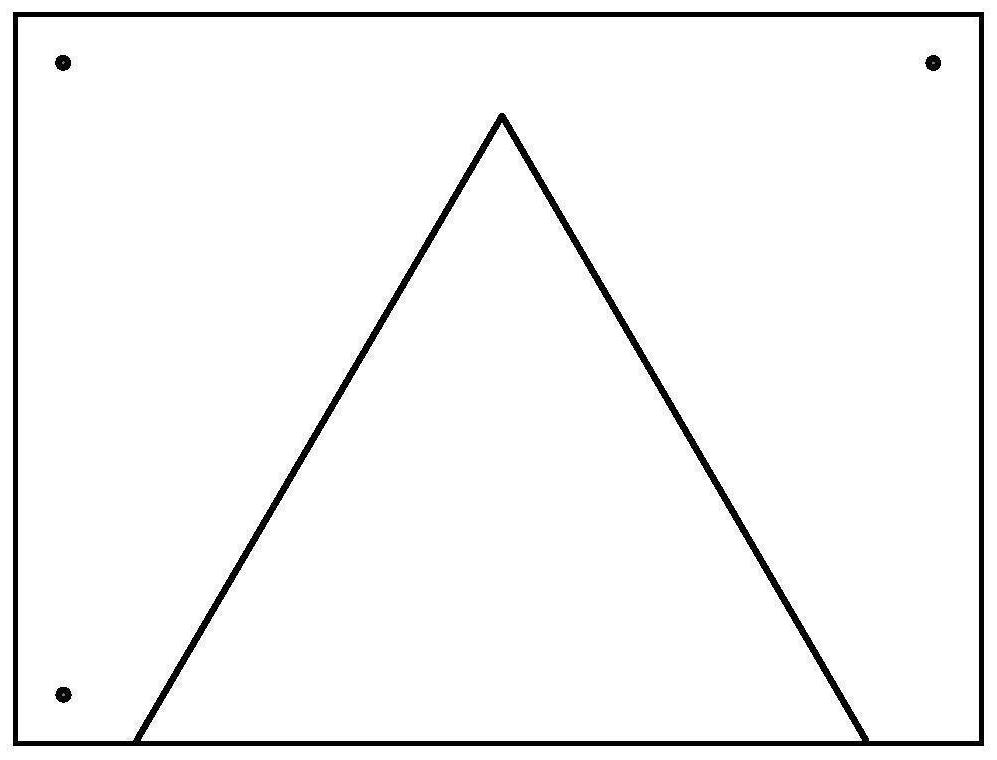

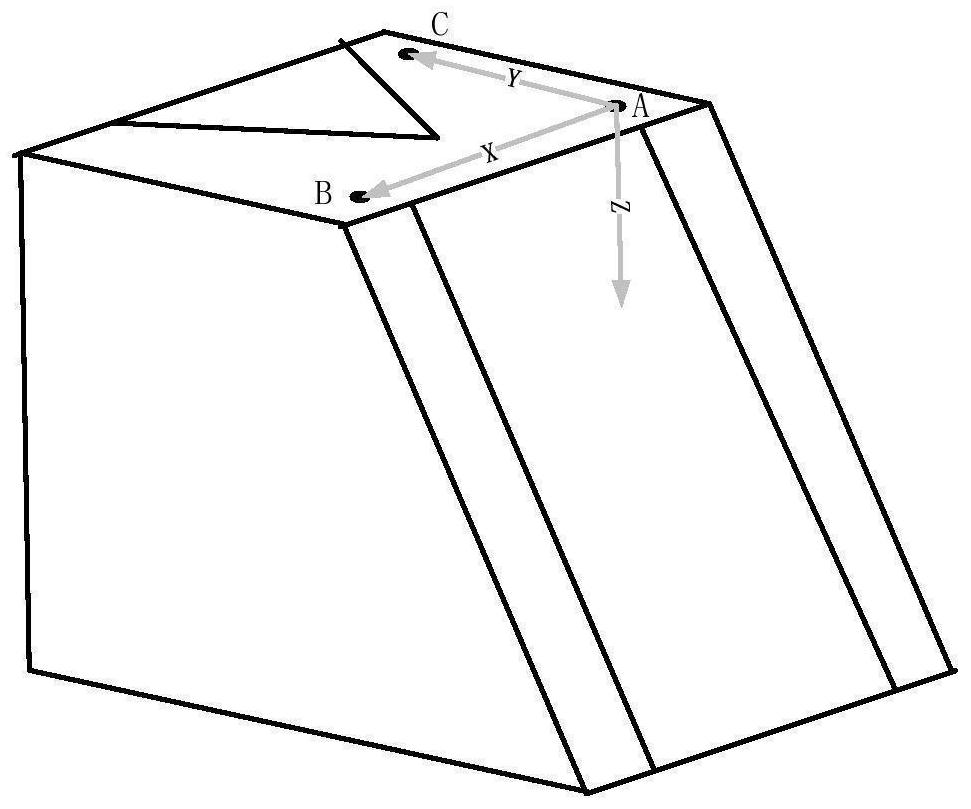

[0051] The invention will be further described in detail below with reference to the accompanying drawings and examples.

[0052] Establish design and user coordinate system 1. The calibration block

[0053] Light applied to the robot structure and a three-dimensional hand-eye camera calibration method, using a calibrated geometrical information block of specially designed, highly accurately estimate a three-dimensional structure of the light relative pose of the camera coordinate system; calibration block mainly comprising a special design on the surface and the ramp surface, the surface having three circular holes and grooves of an isosceles triangle, with a ramp surface on which the parallel groove; figure 1 Shows a schematic view of the surface of the calibration block, three circular holes is used to establish the robot coordinate system user (user coordinate system calibration block), is also used to estimate the relative attitude offline rx, rz, isosceles triangle recess fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com