Electrolytic machining method, cathode for electrolytic machining and electrolytic machining device

A processing method and technology of processing device, which are applied in the direction of processing electrodes, electric processing equipment, electrochemical processing equipment, etc., can solve the problems of inner wall roughness, slag and foreign matter that are not easy to handle, slag and foreign matter in the flow channel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

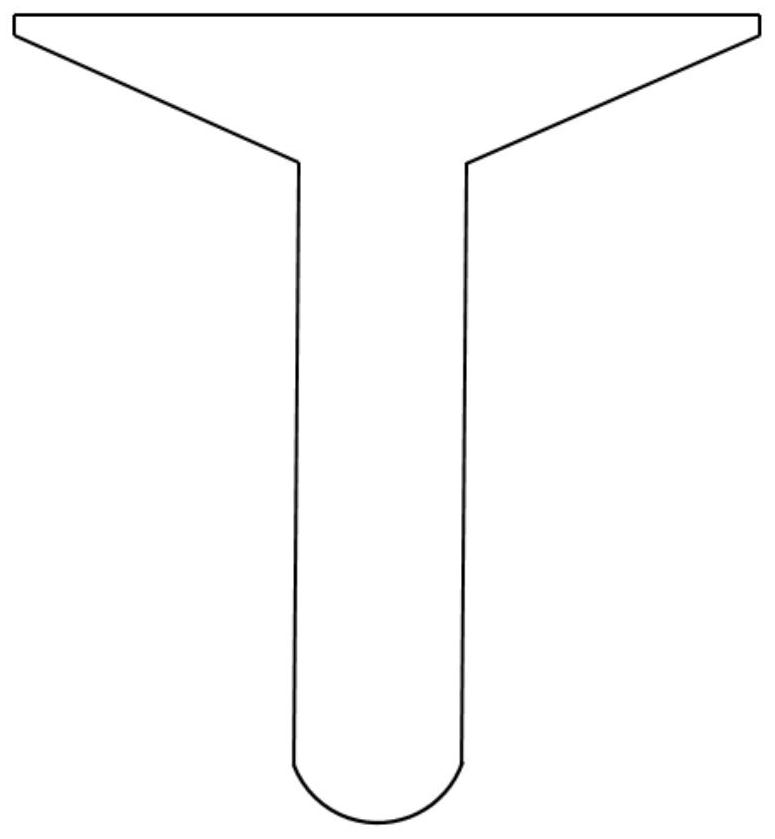

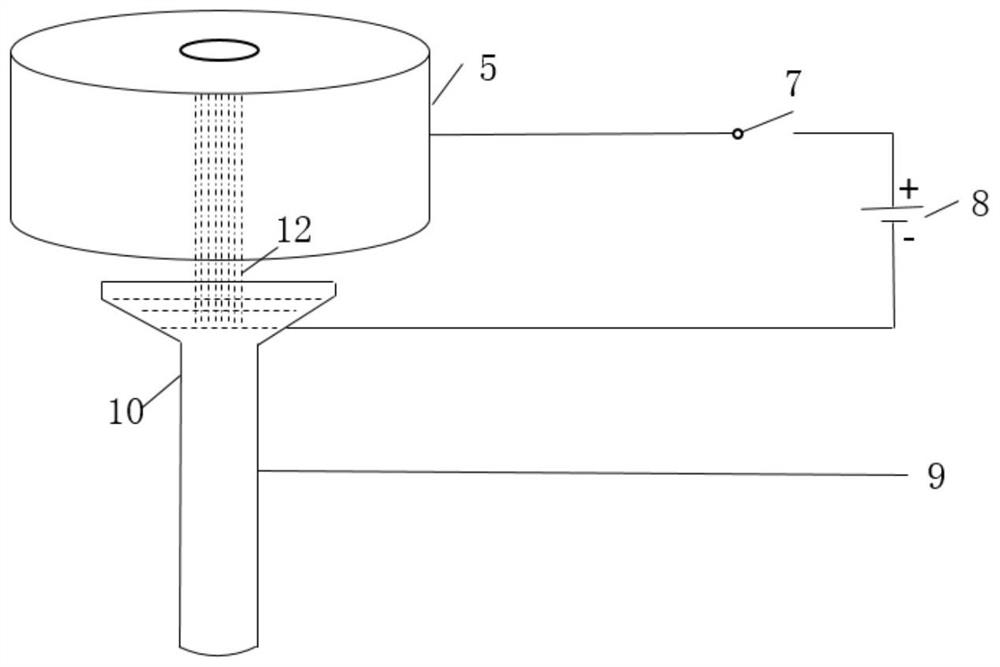

Embodiment Construction

[0026] Unless otherwise specified, terms herein are to be understood according to the knowledge of those of ordinary skill in the relevant art.

[0027] Directional or directional terms such as "inner", "surface", "upper", "lower", "left", "right" described herein are consistent with the corresponding directions or orientations in the accompanying drawings.

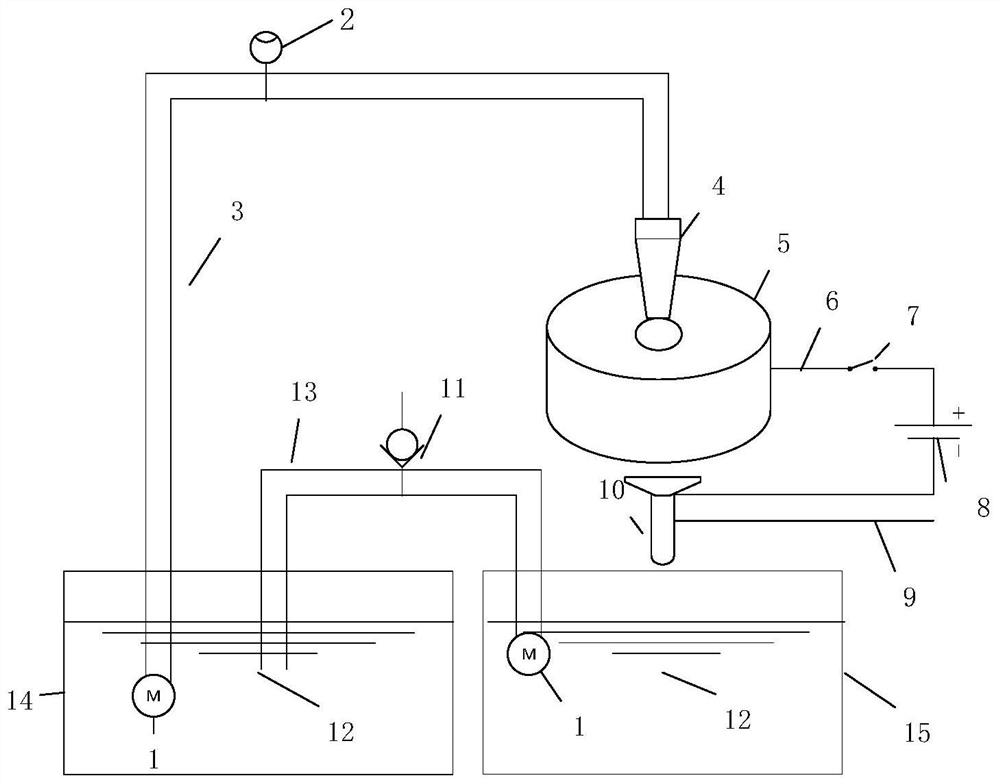

[0028] The electrolyte in the processing method of the present invention is an electrolyte capable of reacting with the rough structure, hanging slag, residual material slag and foreign matter in the internal structure of the part without destroying the original internal structure of the part. Those skilled in the art can make a choice according to the material of the parts in combination with the solutions and effects of the present invention. such as but not limited to NaCl and NaNO 3 mixed solution.

[0029] The cathode material of the present invention is not limited, and conventional cathode materials can be select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com