Ultrasonic vibration assisted electrolysis matrix oblique square hole processing system and method

An ultrasonic vibration and hole processing technology, applied in the field of cavity and electrolytic grinding, deep hole, can solve the problems of stray corrosion, inability to design electrode clamps, etc., to promote breakdown, improve processing accuracy and processing efficiency, The effect of improving machining accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

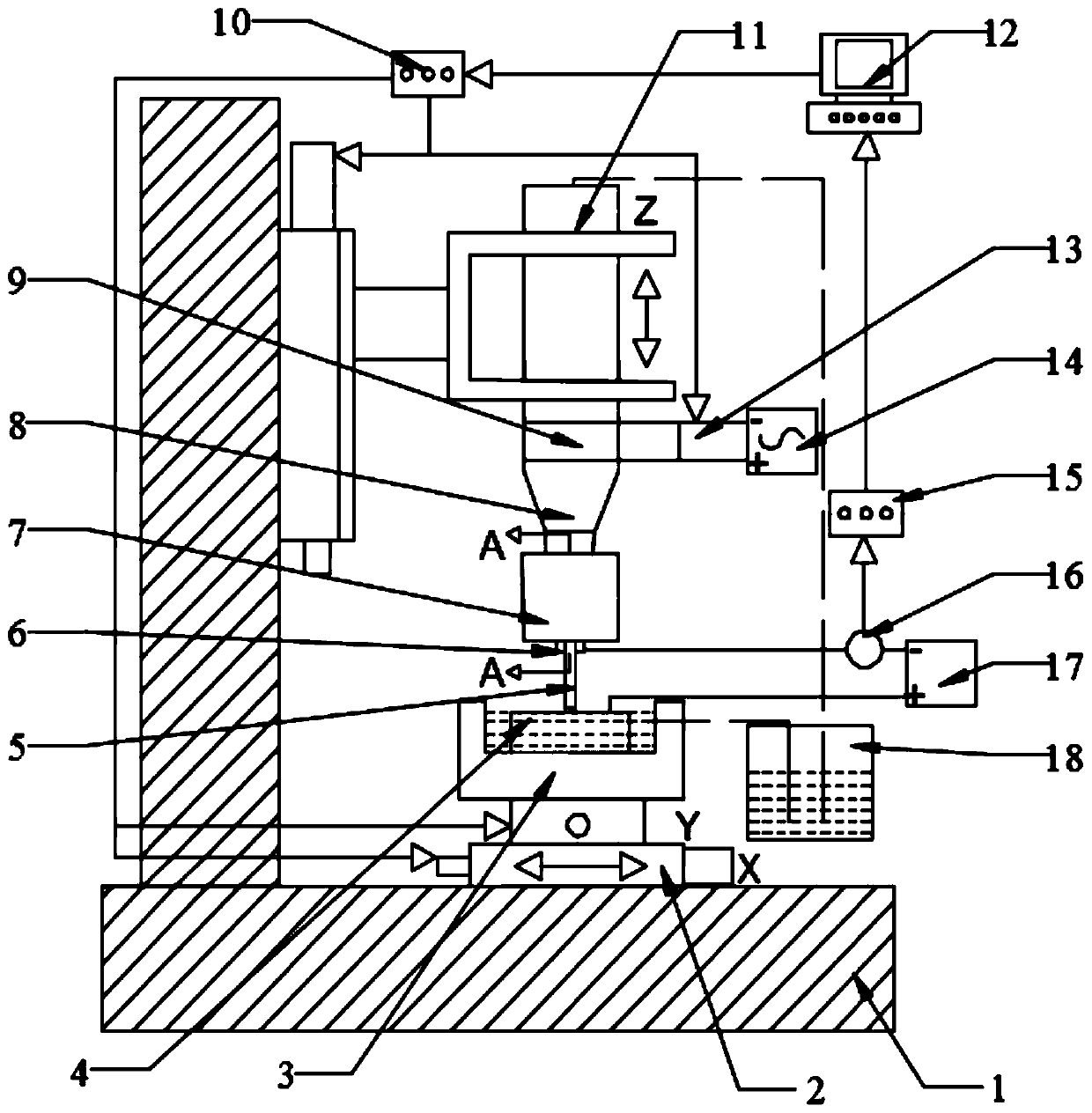

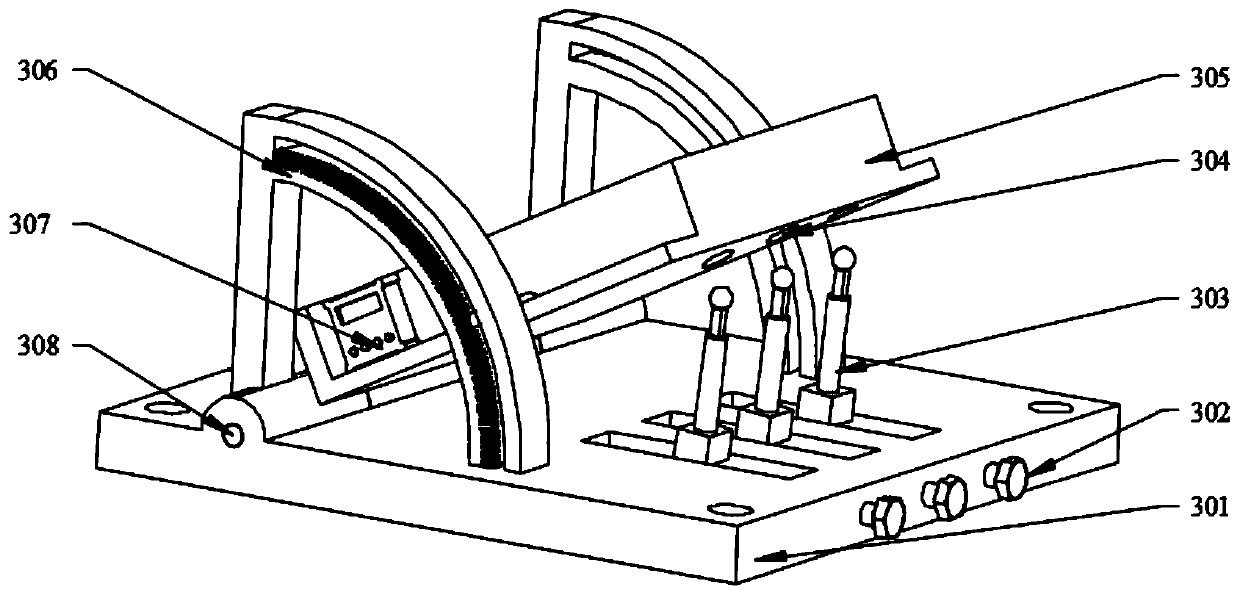

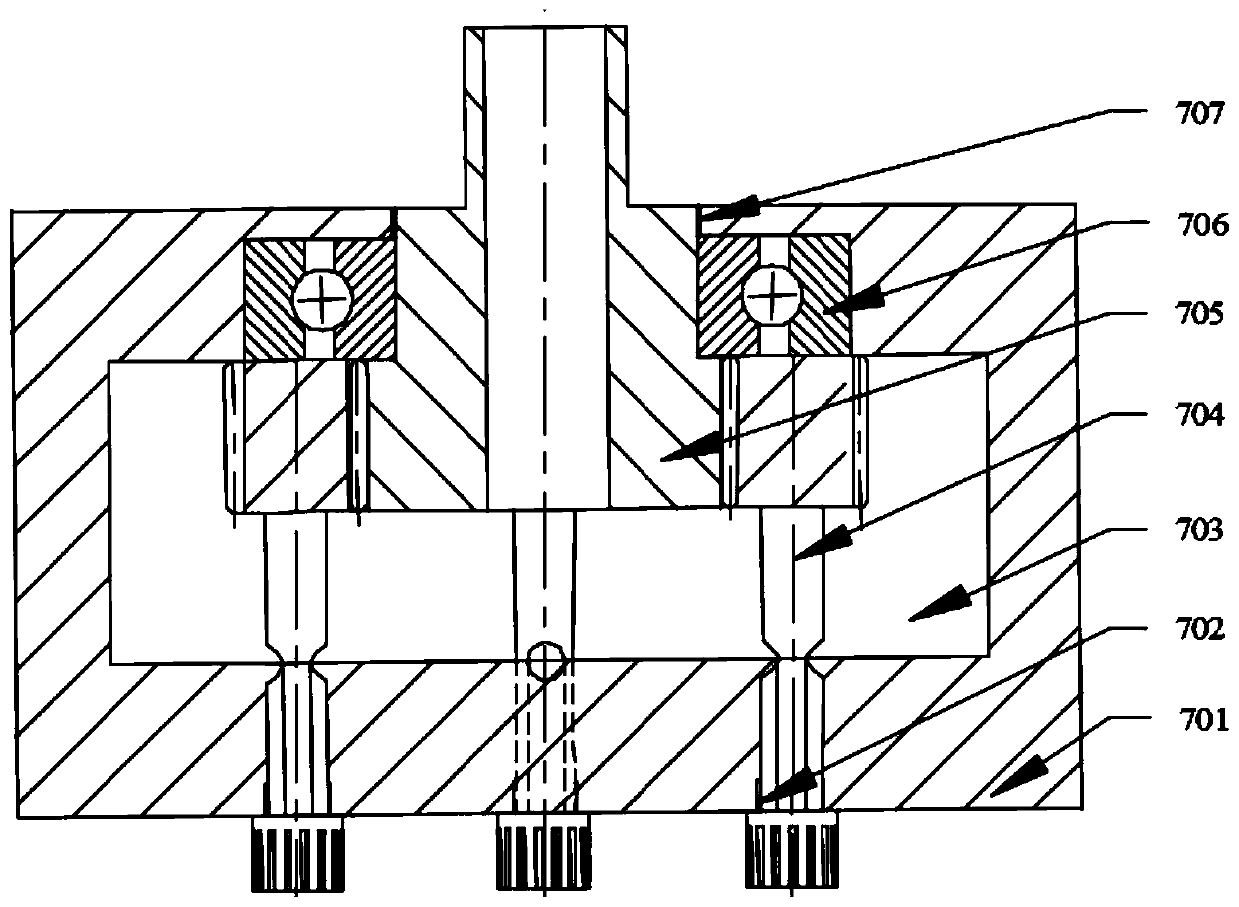

[0049] Such as figure 1 As shown, an ultrasonic vibration-assisted electrolysis matrix oblique hole processing system includes: a column (1), a moving block (2) in X, Y, and Z directions, a workbench (3) (for carrying the workpiece to be processed (4) ), tube electrode (5), conductive ring (6), adapter device (7), horn (8), transducer (9), motion control card (10), hollow electric spindle (11), industrial control Machine (12), ultrasonic generator (13), AC power supply (14), data acquisition card (15), voltage sensor (16), pulse power supply (17), electrolyte circulation device (18). Wherein, the column (1) is provided with movement blocks (2) in X, Y, and Z directions for controlling and driving the movement of the hollow electric spindle (11). A workbench (3) is arranged on the upper end surface of the movement block in the Y direction, and the workbench (3) fixes the workpiece (4) through a clamp. The hollow electric spindle (11) is provided with a transducer (9), the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com