Electric spark milling and mechanical grinding composite machining tool electrode

A compound machining and EDM technology, applied in the direction of electric machining equipment, electrode manufacturing, manufacturing tools, etc., to achieve the effect of avoiding stable arc discharge, reducing processing cost, and reducing grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

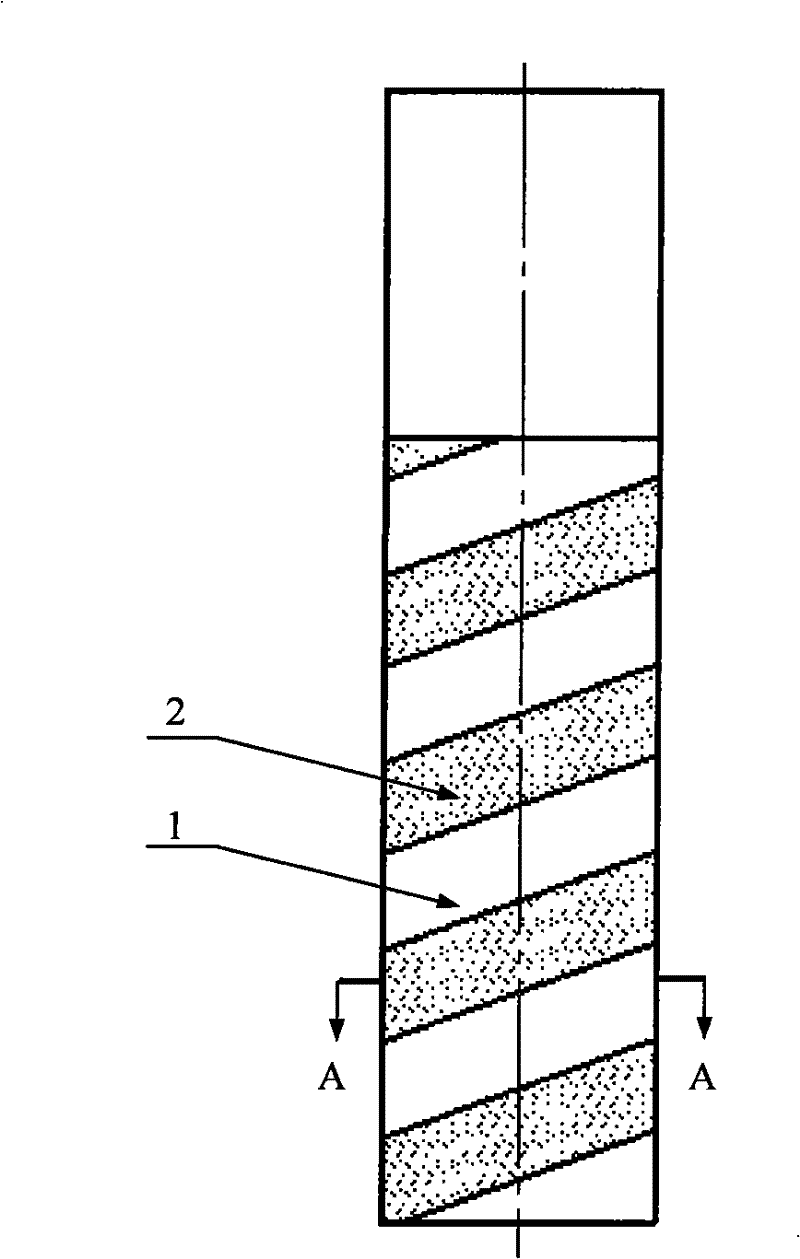

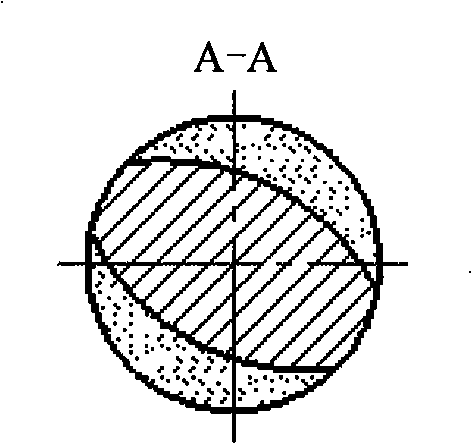

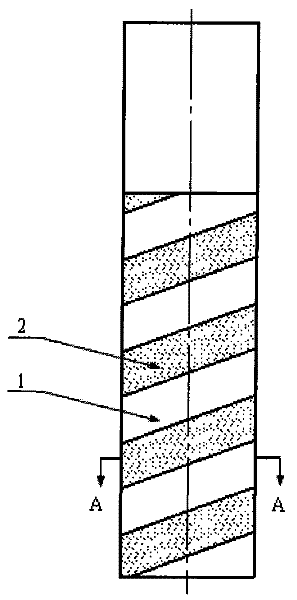

[0014] See attached picture. The combined electric discharge milling and mechanical grinding tool electrode of the present invention includes two parts: a metal tool electrode 1 and a grinding body 2 . First process a metal rod according to the size requirements, then process a spiral groove on the metal rod, and leave the installation length of the tool electrode on the metal rod to make a metal tool electrode 1; It is filled in the spiral groove of the metal tool electrode 1, and the metal tool electrode 1 and the grinding body 2 are consolidated together by sintering or heating; finally, the outer circle of the consolidated tool electrode is ground on a grinding machine to produce an electric Spark milling and mechanical grinding compound processing tool electrode.

[0015] During processing, the tool electrode and the workpiece of the present invention are respectively connected to the two poles of the pulse power supply, and the metal tool electrode 1 in the tool electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com