Large-sized bridge type gantry mixed machining machine tool and machining method thereof

A processing machine tool and bridge technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to control the production cycle, affecting the innovation and development of the industry, and high equipment requirements, so as to improve the processing quality and speed. Responding to customer needs, high efficiency and precision machining

Pending Publication Date: 2017-09-29

NANJING GONGDA CNC TECH

View PDF9 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the other hand, with the further improvement of the industrial system, the demand for large-scale molds and other non-traditional products is becoming more and more extensive, such as the manufacture of wind power blade molds, yacht bases, super-large tires, etc. Large, the length can reach more than 100m, the manufacturing cycle is relatively long, and the requirements for equipment are also very high

The production cycle of end customers' products is difficult to control, and the manufacturing cost increases, which affects the innovation and development of the industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0039] A processing method using the large-scale bridge-type gantry hybrid processing machine tool is characterized in that it includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

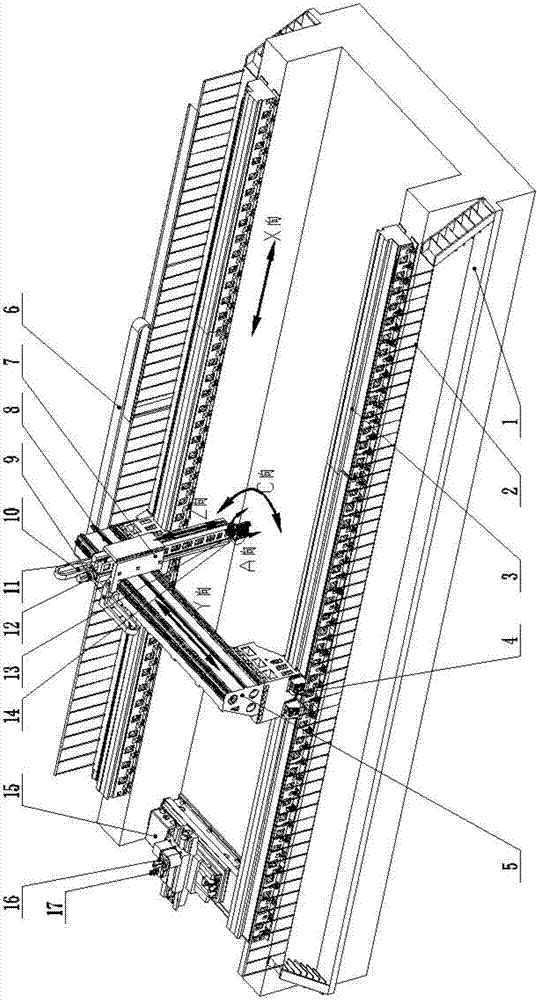

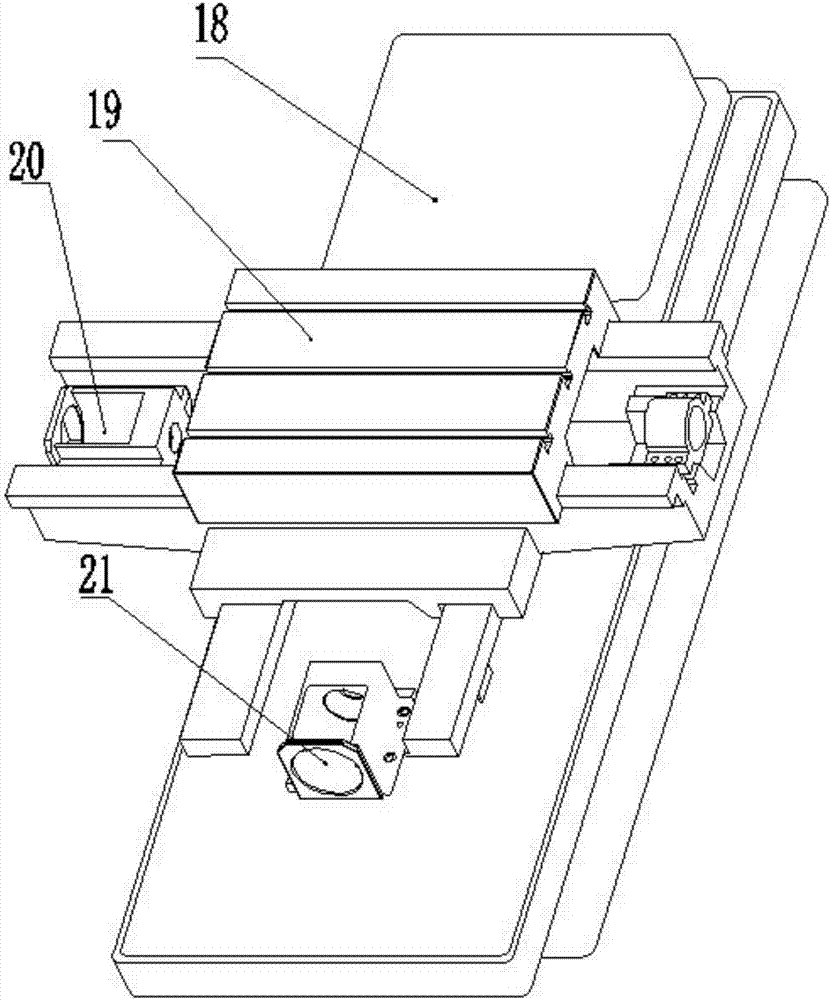

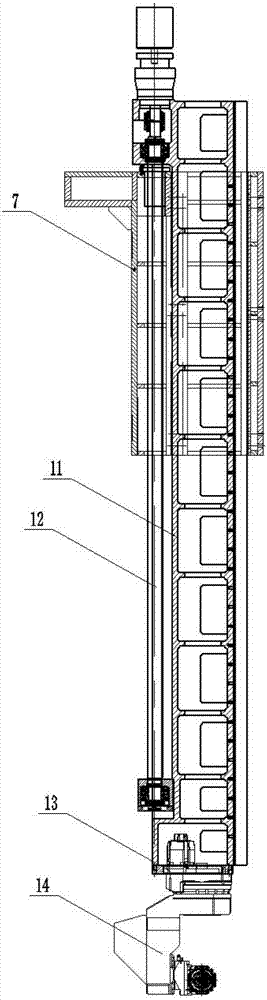

The invention discloses a large-sized bridge type gantry mixed machining machine tool which is characterized by comprising a base (1), a working corridor (2), a machine tool body (3), an X-axis feeding system (4), a cross beam (5), a Y-axis feeding system (8), a slide carriage (7), a square ram (11), a Z-axis feeding system (12), a C-axis feeding system, an A-axis feeding system, an actuation mechanism interface (13) and an actuation unit library (15). By combination of a modern additive manufacturing process and a milling process, efficient and precision machining of a large-size die is realized, and the efficiency is 10 times or much higher than that of machining with a conventional die, but the cost is only 30 percent of that of a conventional process; and the large-sized bridge type gantry mixed machining machine tool meets a customization requirement and intelligence and flexibility requirements in the future and has good prospect. The large-sized bridge type gantry mixed machining machine tool replaces a conventional casting die, can quickly make a response to a demand of a client, and saves the die investment by 60 percent or above.

Description

technical field [0001] The invention relates to a large-scale bridge-type gantry hybrid processing machine tool and a processing method thereof. Its actuator can realize material-adding manufacturing and material-reducing processing, and has an on-machine detection function, belonging to the field of advanced manufacturing equipment. Background technique [0002] Molds can be divided into casting molds, forging molds, die-casting molds, stamping molds and other non-plastic molds, as well as plastic molds. Due to the diversity, complexity and applicability of mold manufacturing, the mold industry is an important part of the manufacturing industry. The mold manufacturing equipment is an important branch of the equipment manufacturing industry, and the country has clearly proposed an important policy of increasing the development of the equipment industry and promoting the localization of key equipment. The mold industry is an important field of high-tech industrialization. Hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P23/04B23Q17/00

CPCB23P23/04B23Q17/00

Inventor 方成刚张金黄筱调

Owner NANJING GONGDA CNC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com