Boring, scraping and rolling integrated compound cutter with adjustable axial distance

An axial distance, compound tool technology, applied in the direction of tools used in lathes, manufacturing tools, accessories of tool holders, etc., can solve problems such as damage, inability to ensure high-precision machining of surface quality, and achieve a high degree of operation automation and overall Good structural reliability and damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

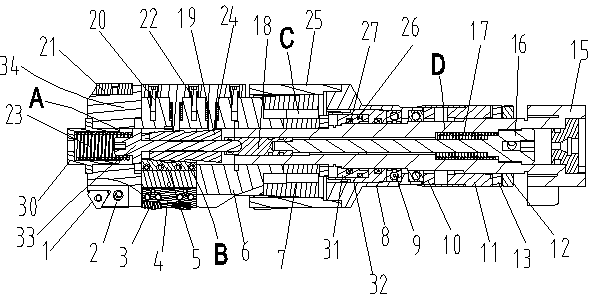

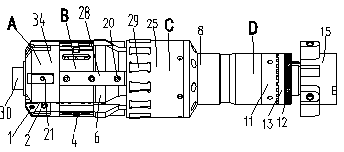

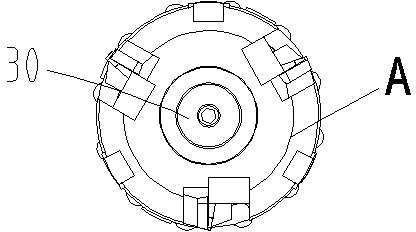

[0030] Such as Figure 1 to Figure 4 As shown, the icon numbers are as follows: Boring head assembly A, scraping head assembly B, roller head assembly C, connecting assembly D, boring blade 1, boring block 2, scraping blade 3, scraper block 4, adjustment support block 5, scraping block Head body 6, core 7, retaining sleeve base 8, rolling bearing 9, adjusting rotary washer 10, adjusting ring 11, locking ring 12, adjusting snap ring 13, hydraulic plug 14, mandrel 15, stroke ejector rod 16, The first spring 17, the spherical connecting rod 18, the sliding core 19, the connecting screw 20, the boring tool supporting guide block 21, the third spring 22, the fourth spring 23, the second spring 24, the retaining sleeve 25, the star seal ring 26 , Rod sealing ring 27, scraper support block 28, needle roller 29, boring head plug body 30, first cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com