Carbon-loaded super-small-size precious metal nanoparticle catalyst and preparation method

A nanoparticle and precious metal technology, which is applied in the field of supporting extremely small particle size precious metal nanoparticle catalysts and its preparation, can solve the problems of not being able to guarantee full loading of precious metal nanoparticles, increasing the preparation cost, and increasing production links, etc., and achieves excellent catalytic ability, high Effective catalytic active area, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A kind of preparation method of the catalyst of activated carbon surface loading ultra-small size noble metal of the present invention, comprises the following steps:

[0041]1) First, commercial activated carbon is mixed with a noble metal precursor, and the noble metal contained in the noble metal precursor is one or any two of Pt, Pd, Ru or Rh (the mass ratio of the two noble metals is any ratio); the added The mass ratio of the noble metal contained in the noble metal precursor to the activated carbon is (0.5-5):100. The corresponding soluble noble metal salts are chloroplatinic acid (H 2 PtCl 6 ·nH 2 O), potassium chloroplatinite (K 2 PtCl 4 ), potassium chloroplatinate (K 2 PtCl 6 ); Potassium chloropalladate (K 2 PdCl 4 ), palladium nitrate (Pd(NO 3 ) 2 ·nH 2 O), potassium chloropalladate (K 2 PdCl 6 ), palladium chloride (PdCl 2 ), sodium tetrachloropalladate (Na 2 PdCl 4 ); ammonium chlororuthenate ((NH 4 ) 2 RuCl 6 ), ruthenium trichloride (...

Embodiment 1

[0045] First, weigh 50 g of commercial activated carbon and noble metal precursor potassium chloropalladate (K 2 PdCl 4 ) mixed, the mass ratio of noble metal palladium (Pd) contained in the added noble metal precursor to commercial activated carbon is 0.5:100. Then add water and ethanol according to the mass ratio of the mixture of commercial activated carbon and noble metal precursor to water and ethanol 10:45:45 to form a suspension containing 10% solids. After fully ultrasonically dispersed, pass it into the spray dryer. Keep the flow rate of the suspension at 200ml / h, set the drying temperature range of the dryer at 100°C, perform rapid atomization drying, and collect the powdery solid precursor. Subsequently, the obtained solid precursor was placed in a muffle furnace, and calcined at 5°C / min to 450°C for 3 hours in a mixture of hydrogen and argon with a mixing ratio of 5:95. The calcined product is C- Pd catalyst.

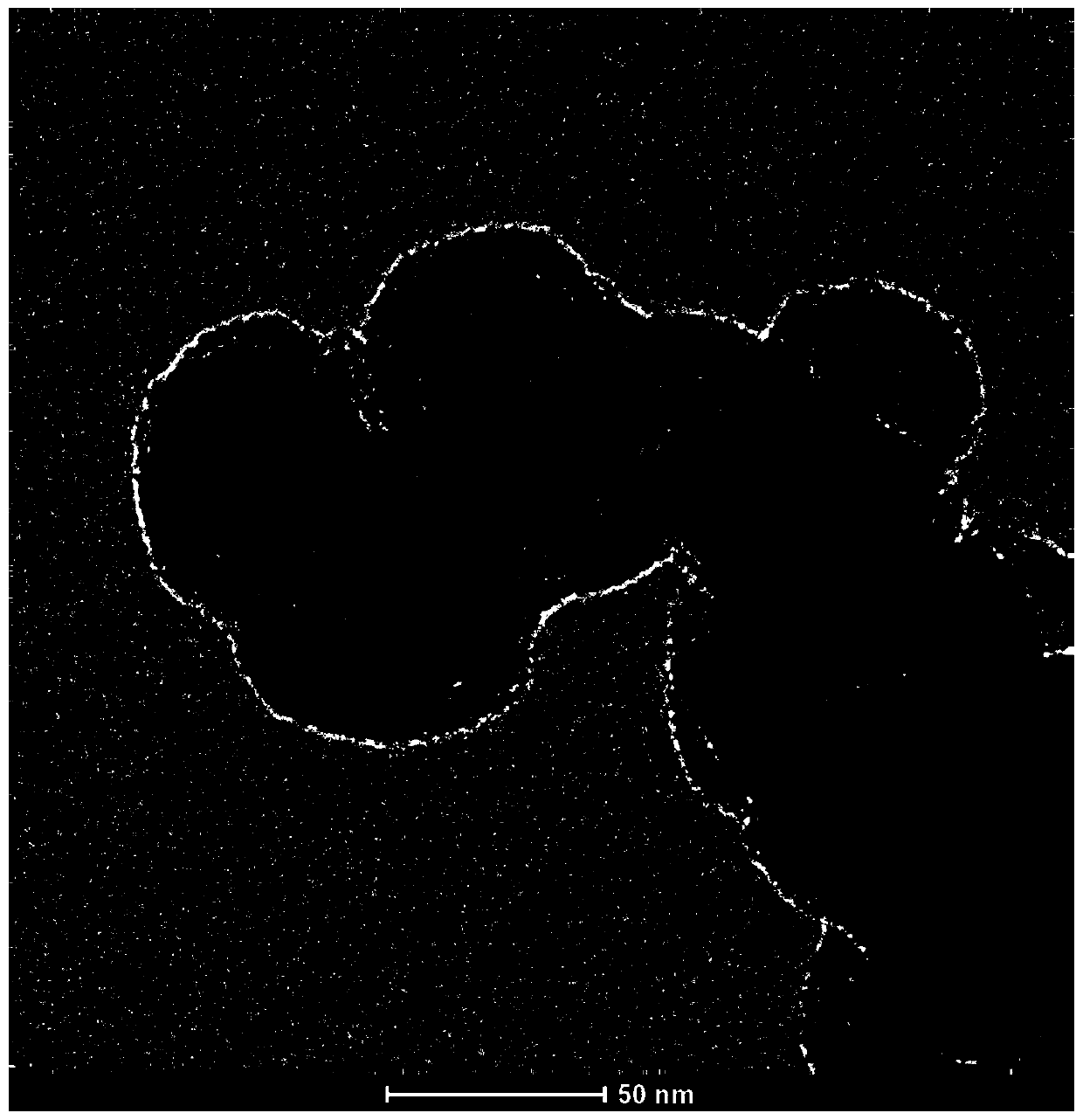

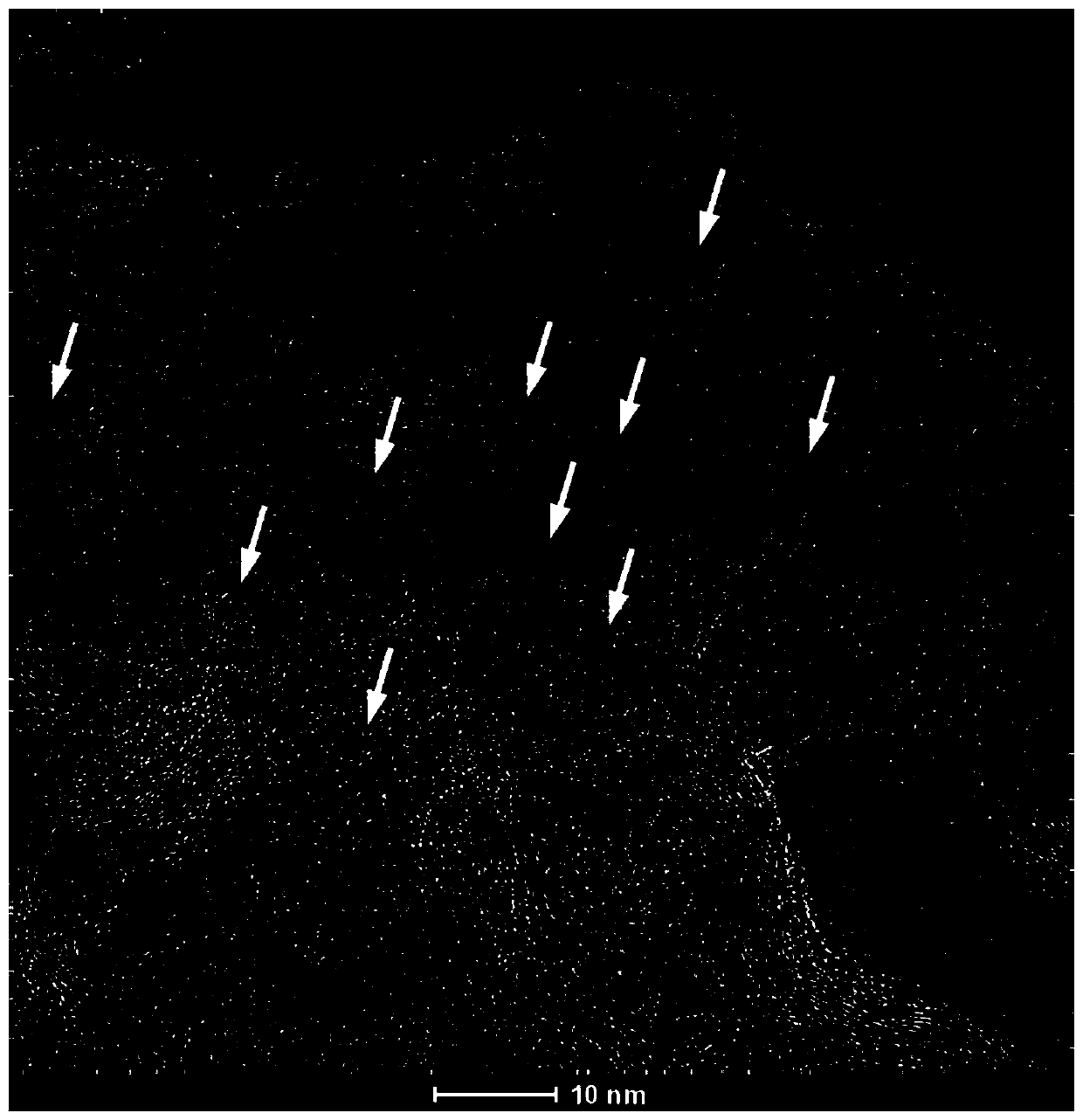

[0046] figure 1 It is a transmission electron micr...

Embodiment 2

[0048] First, weigh 50 g of commercial activated carbon and noble metal precursor chloroplatinic acid (H 2 PtCl 6 ·nH 2 O) mixing, the mass ratio of noble metal platinum (Pt) contained in the added noble metal precursor to activated carbon is 1:100. Then add water and ethanol according to the mass ratio of the mixture of activated carbon and noble metal precursor to water and ethanol 10:45:45 to form a suspension containing 10% solids. After fully ultrasonically dispersed, pass it into a spray dryer and keep The flow rate of the suspension is 100ml / h, and the drying temperature of the dryer is set at 140°C for rapid atomization and drying to collect the powdery solid precursor. Subsequently, the obtained solid precursor was placed in a muffle furnace, and calcined at 5°C / min to 300°C for 7 hours in a mixture of hydrogen and nitrogen with a mixing ratio of 5:95, and the calcined product was C-Pt catalyst.

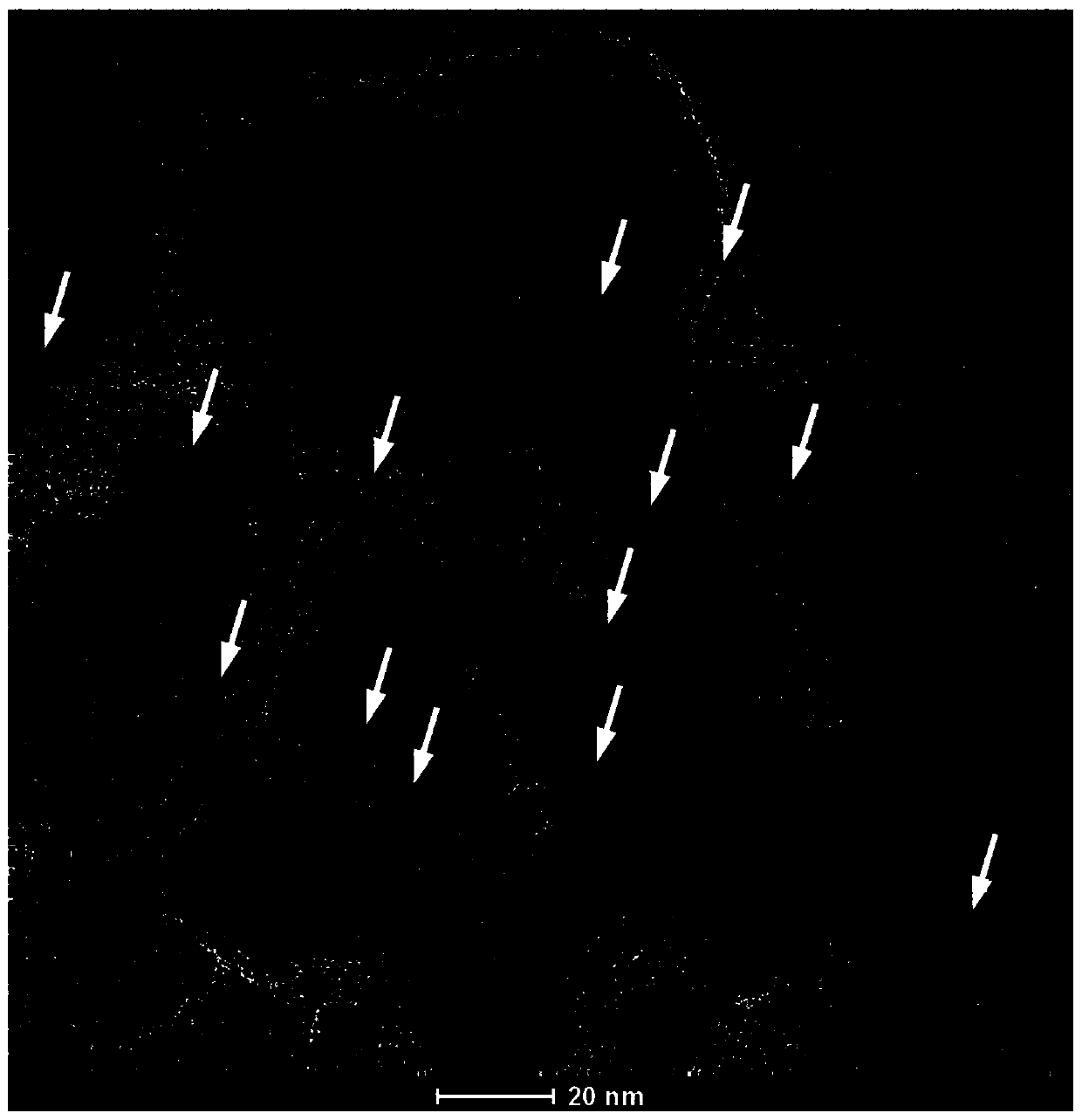

[0049] image 3 It is a transmission electron microscope image of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com