Preparation method of organic-inorganic hybrid material coated nickel silicate nanotube catalyst

A hybrid material, nickel silicate technology, applied in the direction of physical/chemical process catalysts, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of reducing active centers, reducing reactivity, affecting molecular diffusion of reactants and products, etc. Achieve the effects of inhibiting nucleation, improving anti-carbon performance, good stability and anti-carbon performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

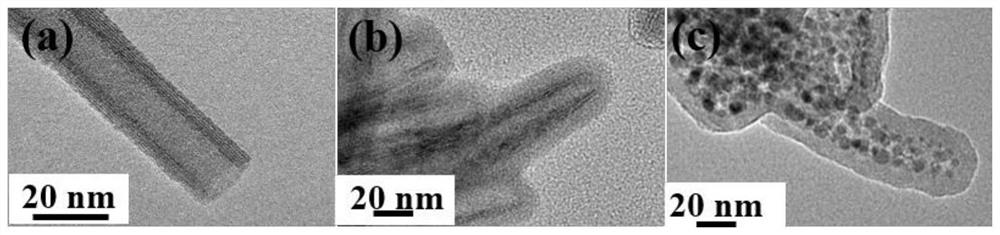

[0035] Preparation of nickel silicate nanotubes 40 milliliters of 0.5mol / L sodium silicate solution was poured into 150 milliliters of 0.7mol / L NiCl under stirring conditions 2 ·6H 2 O aqueous solution, after 10 minutes, 29g NaOH was added to the above mixed solution at one time, stirred for 10 minutes, put into a crystallization kettle for crystallization at 210°C for 24 hours. The obtained precipitate was washed three times with water and washed with alcohol three times, and then dried overnight at 60° C. to obtain a nickel silicate nanotube precursor.

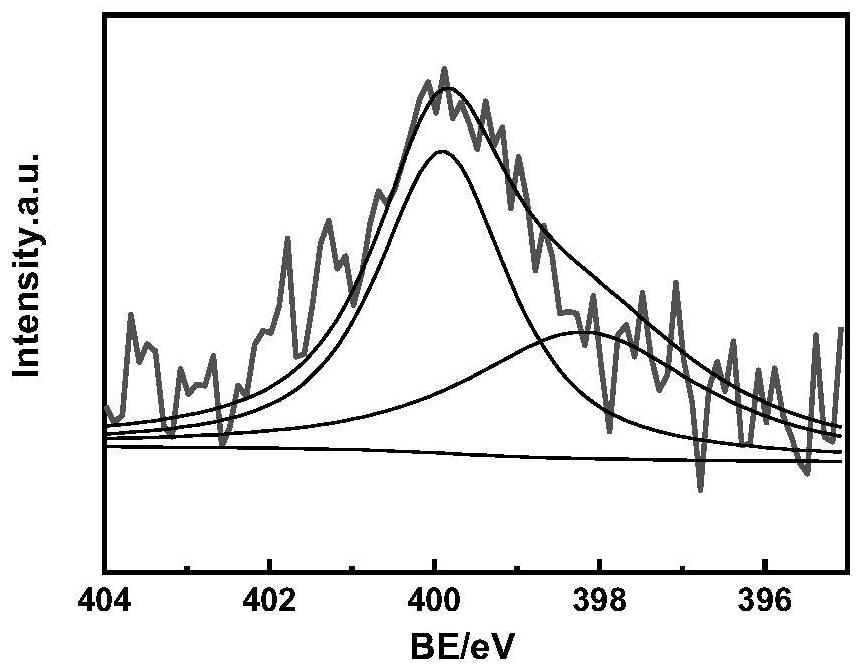

[0036] Organic-inorganic hybrid material-coated nickel silicate nanotube catalyst was prepared by direct synthesis and functionalization: 0.1g nickel silicate nanotube and 0.4g hexadecyltrimethylammonium bromide were dispersed in 30ml deionized water and 90ml anhydrous In the mixed solution of ethanol, sonicate for 2h. Then, under stirring, 3 ml of ammonia water was introduced. Mix 112.5 μL 3-aminopropyltriethoxysilane (A...

Embodiment 2

[0040] Preparation of nickel silicate nanotubes: 40 milliliters of 0.5mol / L sodium silicate solution was poured into 150 milliliters of 0.7mol / L NiCl under stirring conditions 2 ·6H 2 O aqueous solution, after 10 minutes, 29g NaOH was quickly added to the above mixed solution, stirred for 10 minutes, and placed in a crystallization kettle for crystallization at 210°C for 24 hours. The obtained precipitate was washed three times with water and washed with alcohol three times, and then dried overnight at 60° C. to obtain a nickel silicate nanotube precursor.

[0041] Post-synthesis functionalization Synthesis of organic-inorganic hybrid material coated nickel silicate nanotube catalyst, 0.1g nickel silicate nanotube and 0.4g hexadecyltrimethylammonium bromide dispersed in 30ml deionized water and 90ml absolute ethanol In the mixed solution, ultrasonic 2h. Then, under stirring, 3 ml of ammonia water was introduced. Mix 112.5 μL tetraethyl orthosilicate in 25 ml absolute ethano...

Embodiment 3

[0044] The other steps were the same as in Example 1, changing the addition amount of APTES to 75 μL and the addition amount of TEOS to 225 μL, the methane conversion rate dropped to 72% after 60h activity evaluation, resulting in 1.51% carbon deposition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com