A preparation method of nano carbide reinforced aluminum matrix composite welding wire

A composite material and enhanced aluminum-based technology, applied in the field of aluminum alloy materials, can solve the problems of low production efficiency, high price of carbide nanoparticles, and high comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

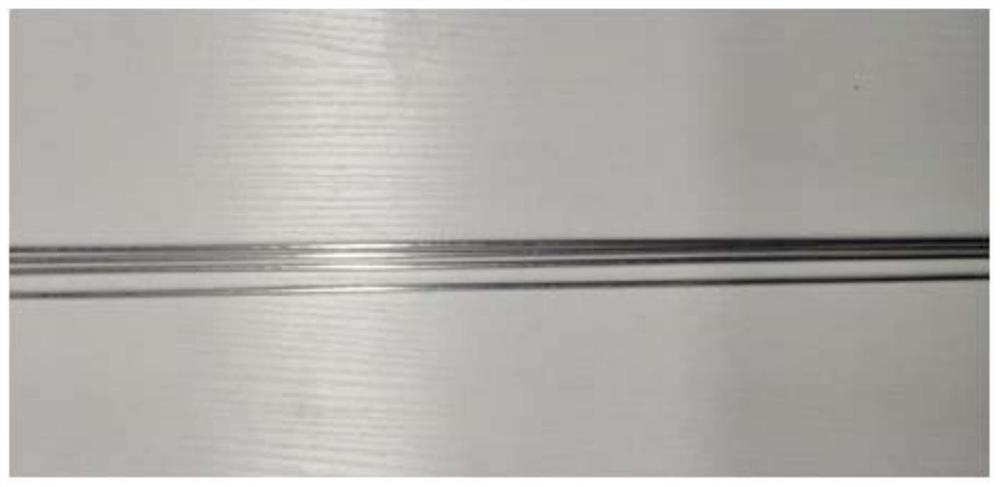

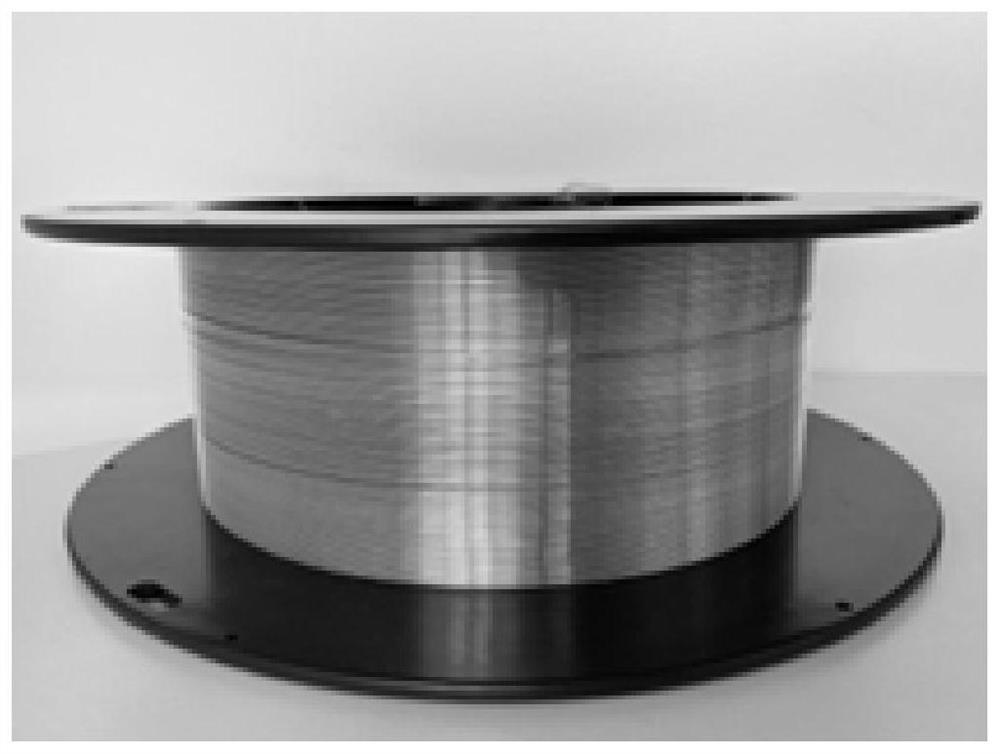

[0039] In this embodiment, a new type of nanometer titanium carbide (TiC) ceramic particle reinforced aluminum matrix composite welding wire includes the following components by mass ratio: 7075 (5.1%-6.1% Zn, 2.1%-2.9% Mg, 1.2%-2.0 %Cu, the rest is Al, the content of each element is based on the total weight of various metal elements), 2% (the content of nanoparticles is based on the total weight of nanoparticles and metal matrix), the diameter is 40-110nm (the average diameter is 100nm below) of TiC nanoparticles. The production process is divided into three parts, first in-situ synthesis of titanium carbide nanoparticles reinforced pure aluminum composite material, the mass fraction of TiC nanoparticles in the pure aluminum composite material is 10%, and then the pure aluminum composite material is used to configure the alloy and prepare the ingot Finally, the ingot is extruded and wire-drawn to obtain nano-carbide ceramic particle-reinforced aluminum matrix composite weldi...

Embodiment 2

[0054] In this embodiment, a new type of nano-zirconium carbide (ZrC) ceramic particle reinforced aluminum matrix composite material welding wire includes the following components by mass ratio: 2024 (3.8%-4.9% Cu, 1.2%-1.8% Mg, the rest is Al, The content of each element is based on the total weight of various metal elements), and 2% (the content of nanoparticles is based on the total weight of nanoparticles and metal matrix) ZrC nanoparticles with a diameter of 60-120nm (average diameter below 100nm).

[0055] The production process is divided into three parts, first in situ synthesis of zirconium carbide nanoparticles reinforced pure aluminum composite material, the mass fraction of ZrC nanoparticles in the pure aluminum composite material is 15%, and then the pure aluminum composite material is used to configure the alloy and prepare the ingot Finally, the ingot is extruded and wire-drawn to obtain nano-carbide ceramic particle-reinforced aluminum matrix composite welding w...

Embodiment 3

[0069] In this embodiment, a new type of nano-zirconium carbide (ZrC) ceramic particle reinforced aluminum matrix composite material welding wire includes the following components by mass ratio: 2024 (3.8%-4.9% Cu, 1.2%-1.8%, Mg and the rest are Al, The content of each element is based on the total weight of various metal elements), and 2% (the content of nanoparticles is based on the total weight of the nano particles and the metal matrix) ZrC nanoparticles with a diameter of 40-100nm.

[0070] The production process is divided into three parts, first in situ synthesis of zirconium carbide nanoparticles reinforced pure aluminum composite material, the mass fraction of ZrC nanoparticles in the pure aluminum composite material is 20%, and then the pure aluminum composite material is used to configure the alloy and prepare the ingot Finally, the ingot is extruded and wire-drawn to obtain nano-carbide ceramic particle-reinforced aluminum matrix composite welding wire.

[0071] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com