Preparation method and application of artificial humus/iron mineral co-precipitated composite material

A composite material and iron mineral technology, applied in the field of iron mineral composite material preparation, can solve the problems of unfavorable popularization and application, high preparation cost, single synthesis method, etc., and achieve the goal of reducing dispersion, improving recovery efficiency and increasing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

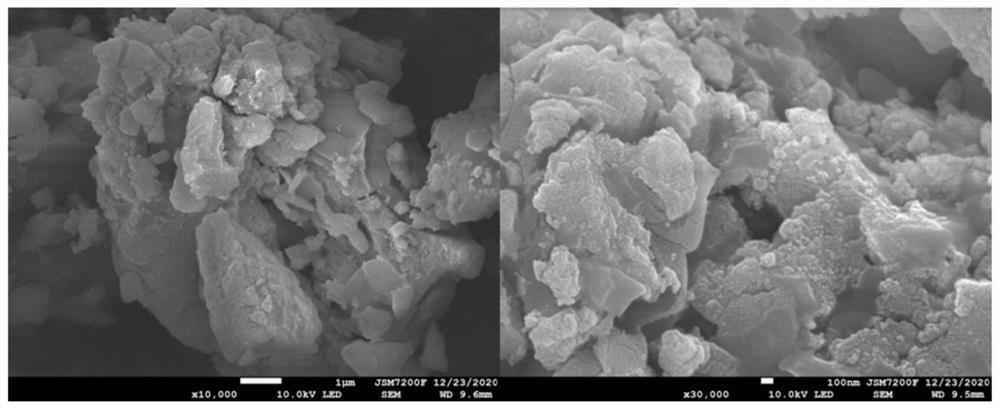

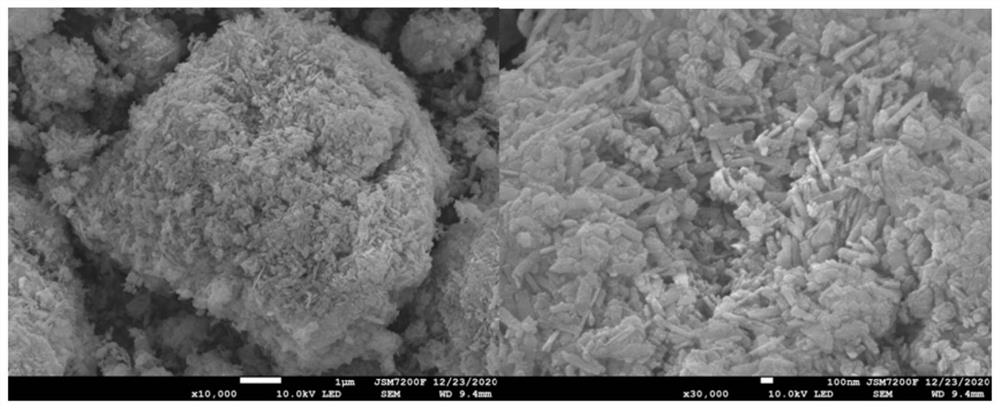

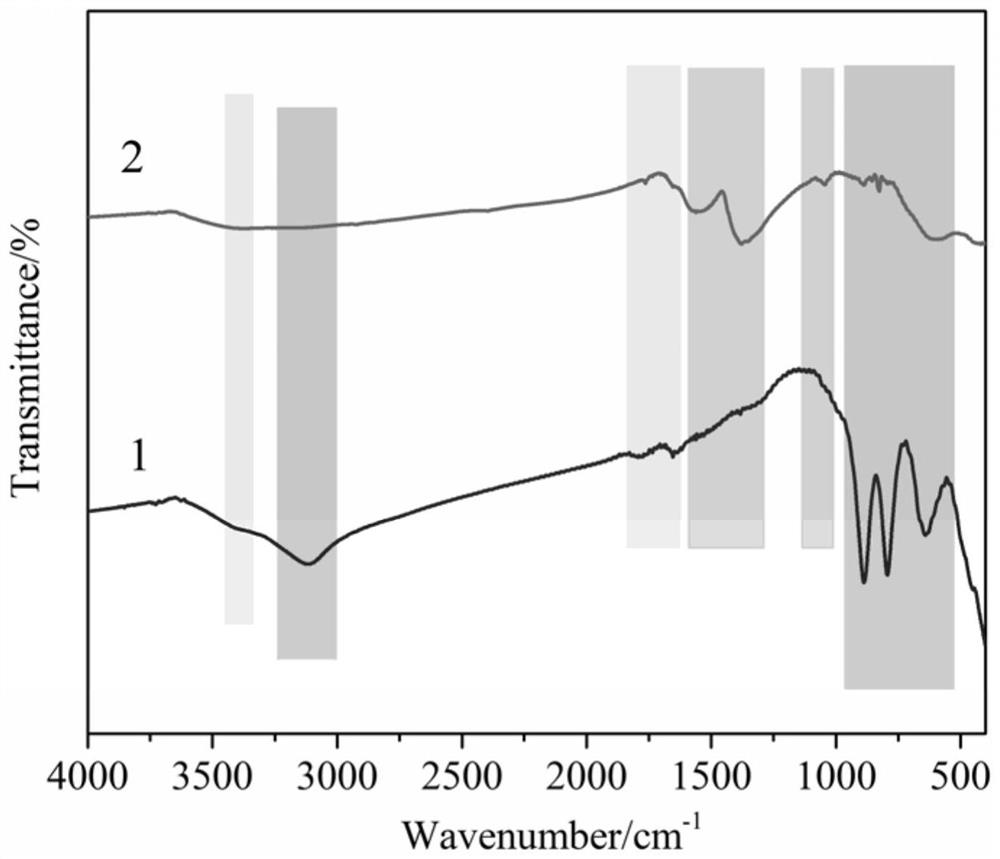

Image

Examples

specific Embodiment approach 1

[0041] Specific embodiment one: this embodiment is a kind of preparation method of artificial humus / iron mineral co-precipitation state composite material is completed according to the following steps:

[0042] 1. First, wash, dry and grind the biomass waste, then add the biomass powder into the strong alkaline aqueous solution, and transfer it to a high-pressure reactor for hydrothermal humification reaction to obtain the reaction product I; The reaction product I is filtered, and the liquid is collected to obtain a hydrothermal humification liquid product;

[0043] 2. Dissolving the solid iron metal salt in water first, and then strengthening the alkaline solution drop by drop until the pH value of the solution reaches 12-14 to obtain the iron mineral precursor;

[0044] 3. Add the hydrothermal humification liquid product dropwise to the iron mineral precursor, stir, and then age in a water bath at a constant temperature to obtain the reaction product II; centrifuge the reac...

specific Embodiment approach 2

[0048] Embodiment 2: This embodiment differs from Embodiment 1 in that the biomass waste described in step 1 is leaves, rice straw, corn straw or soybean straw. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0049] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the strong alkaline aqueous solution described in step one is that strong base is dissolved in deionized water, wherein the quality of strong base is the same as that of deionized water The volume ratio is (1g~6g):(100mL~220mL); the strong base is NaOH or KOH. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com