Al2O3-coated modified lithium nickel manganese oxide positive electrode material and preparation method thereof

A technology of lithium nickel manganate and cathode material, applied in the field of lithium nickel manganate cathode material and its preparation, can solve the problems of uneven coating layer, inconsistent crystal growth rate and nucleation rate, etc., and achieves high safety and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

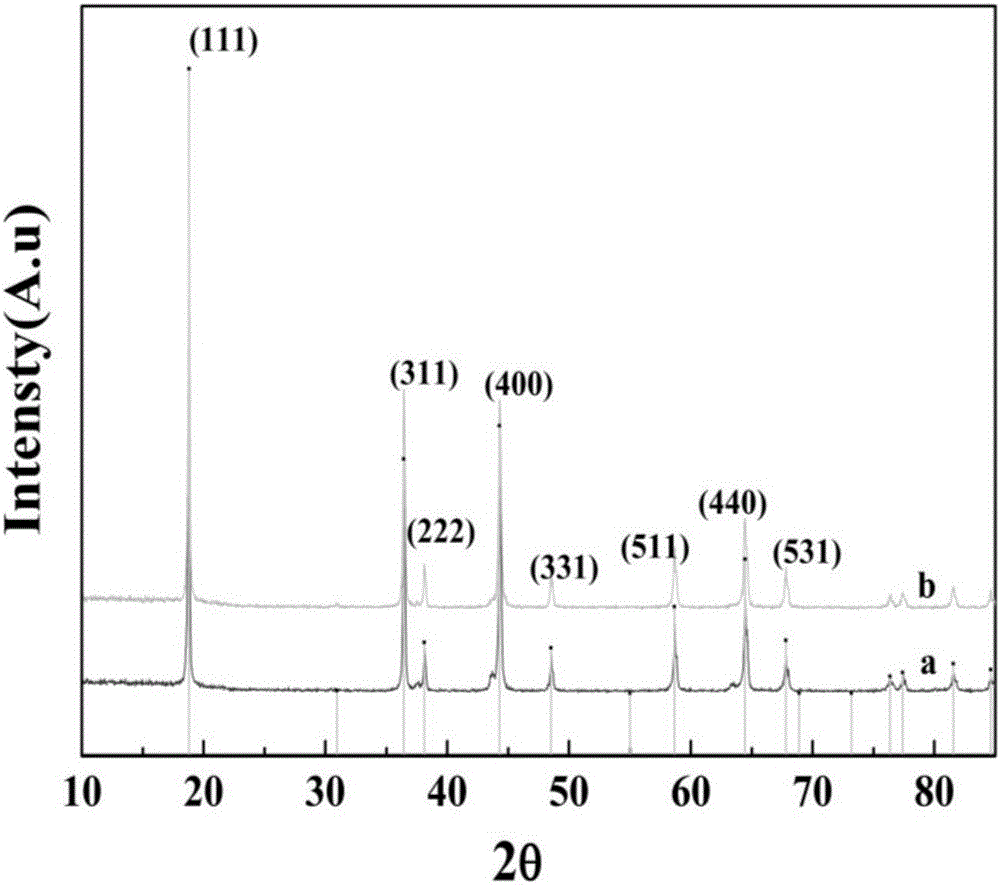

[0034] a kind of Al 2 o 3 Coated modified lithium nickel manganese oxide cathode material, the preparation method of which comprises the following steps:

[0035] (1) with Al 2 o 3 The amount of coating is 1% of the mass of lithium nickel manganese oxide material to calculate the molar number of aluminum element, and then calculate the Al(NO 3 ) 3 , NaAlO 2 The number of moles and mass of Al(NO 3 ) 3 and NaAlO 2 , and were formulated into Al(NO 3 ) 3 solution, 0.5mol / L NaAlO 2 solution;

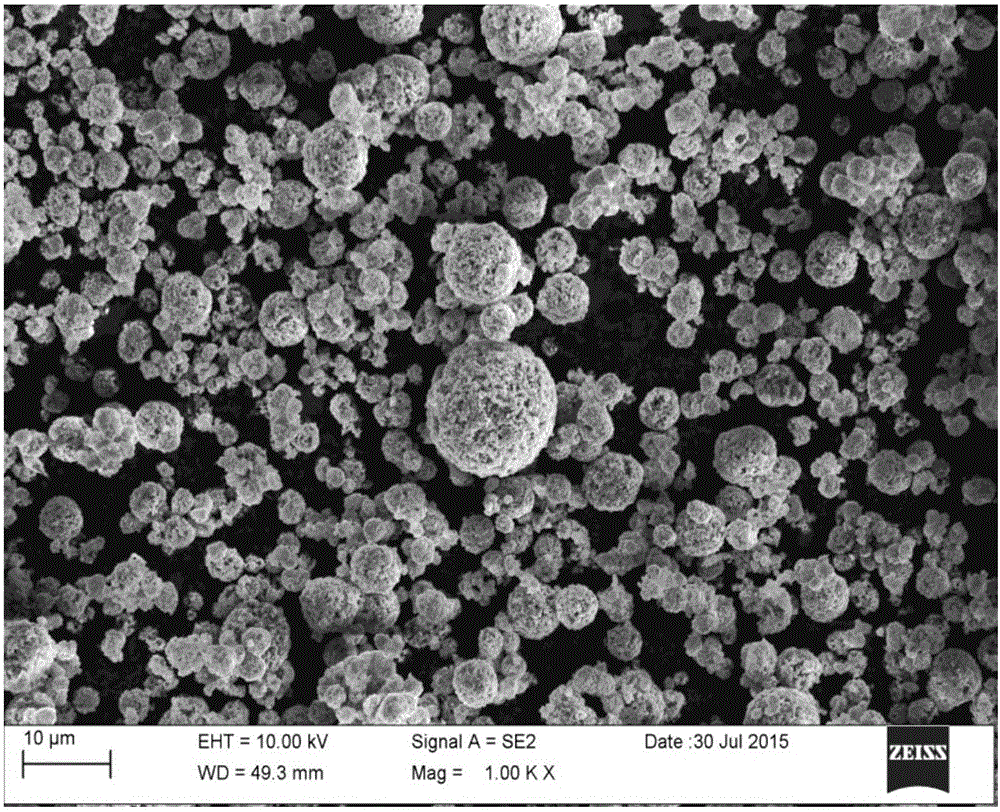

[0036] (2) Weigh lithium nickel manganese oxide, and ultrasonically disperse it in deionized water according to the ratio of lithium nickel manganese oxide: water = 1g: 30mL to form a suspension, and add 1.5% of the mass of lithium nickel manganese oxide to the suspension Sodium dodecylbenzenesulfonate, ultrasonically dispersed for 15min;

[0037] (3) Slowly add the prepared Al(NO 3 ) 3 30% of the volume of the solution, and ultrasonic 15min, then dropwise added the prepared Na...

Embodiment 2

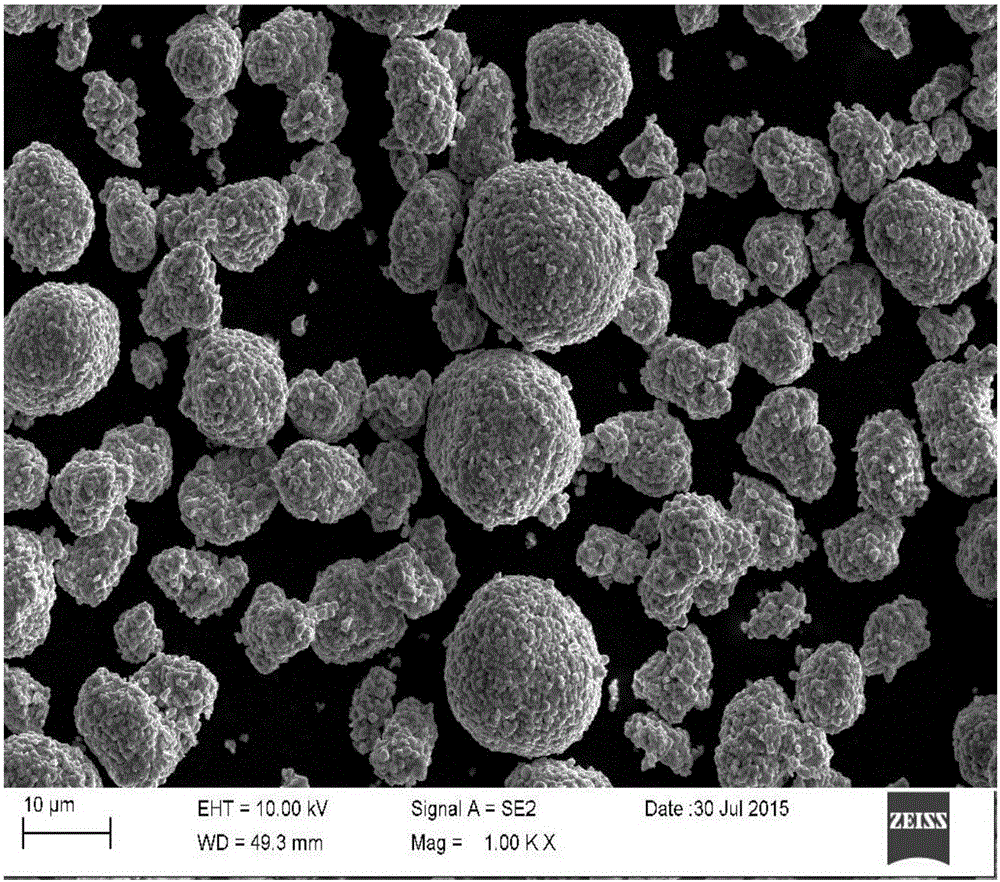

[0043] a kind of Al 2 o 3 Coated modified lithium nickel manganese oxide cathode material, the preparation method of which comprises the following steps:

[0044] (1) with Al 2 o 3 The amount of coating is 3% of the mass of lithium nickel manganese oxide material to calculate the molar number of aluminum element, and then calculate the Al(NO 3 ) 3 , NaAlO 2 The number of moles and mass of Al(NO 3 ) 3 and NaAlO 2 , and were formulated into Al(NO 3 ) 3 solution, 0.5mol / L NaAlO 2 solution;

[0045] (2) Weigh lithium nickel manganese oxide, and ultrasonically disperse it in deionized water according to the ratio of lithium nickel manganese oxide: water = 1g: 30mL to form a suspension, and add 2.5% of the mass of lithium nickel manganese oxide to the suspension Sodium dodecylbenzenesulfonate, ultrasonically dispersed for 20min;

[0046] (3) Slowly add the prepared Al(NO 3 ) 3 30% of the solution volume, and ultrasonic 20min, then dropwise added the prepared NaAlO 2 ...

Embodiment 3

[0054] a kind of Al 2 o 3 Coated modified lithium nickel manganese oxide cathode material, the preparation method of which comprises the following steps:

[0055] (1) with Al 2 o 3 The amount of coating is 5% of the mass of lithium nickel manganese oxide material to calculate the molar number of aluminum element, and then convert Al(NO 3 ) 3 , NaAlO 2 The number of moles and mass of Al(NO 3 ) 3 and NaAlO 2 , and were formulated into Al(NO 3 ) 3 solution, 0.5mol / L NaAlO 2 solution;

[0056] (2) Weigh lithium nickel manganese oxide, and ultrasonically disperse it in deionized water according to the ratio of lithium nickel manganese oxide: water = 1g: 30mL to form a suspension, and add 3.5% of the mass of lithium nickel manganese oxide to the suspension Sodium dodecylbenzenesulfonate, ultrasonically dispersed for 30min;

[0057] (3) Slowly add the prepared Al(NO 3 ) 3 30% of the volume of the solution, and ultrasonic 30min, then dropwise added the prepared NaAlO to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com