Production method for food-grade potassium metabisulfite

A technology of potassium pyrosulfite and its production method, which is applied in the chemical industry and can solve problems such as inability to filter, failure to meet use requirements, and difficulty in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

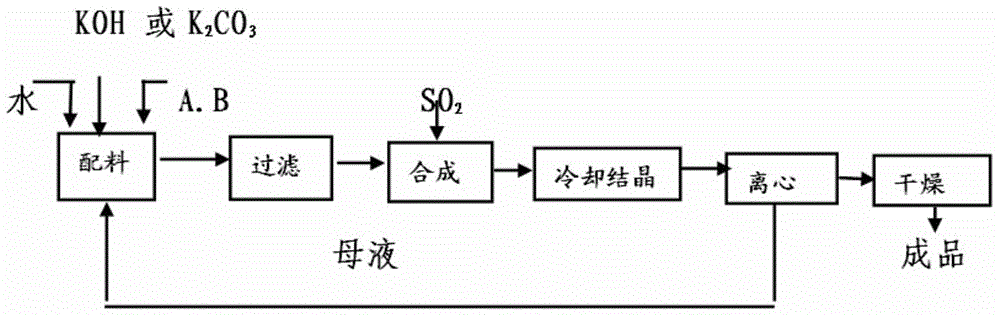

Method used

Image

Examples

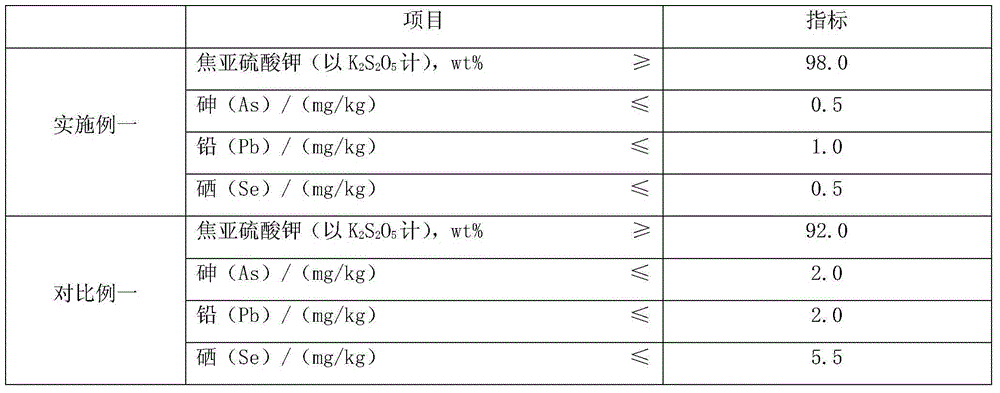

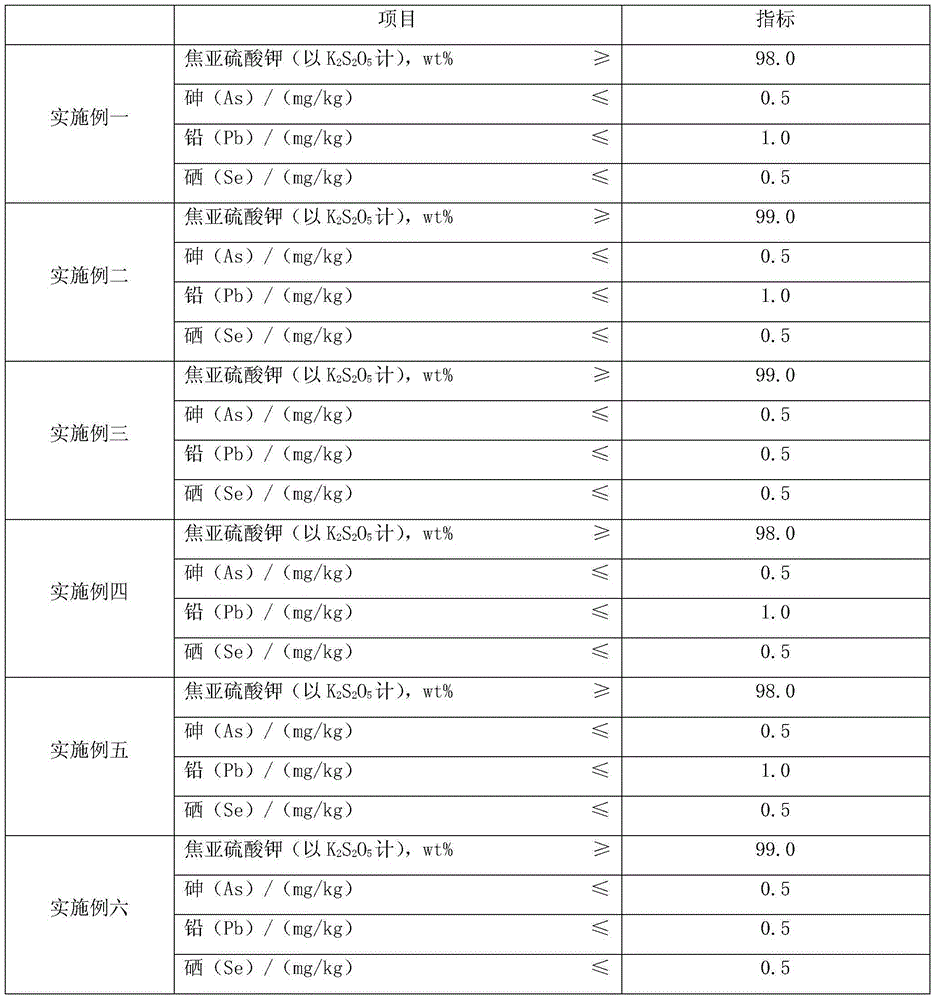

Embodiment 1

[0043] (1) Potassium metabisulfite mother liquor and potassium hydroxide are used to form a solution, wherein the solution contains K + 400g / L, add impurity remover A, auxiliary agent B, preferably, impurity remover A adopts activated carbon, auxiliary agent B adopts modified diatomite, and the weight ratio of activated carbon to modified diatomite is 2:1, and then Filter through a microporous filter device with a pore size of 5 μm to obtain a clear solution.

[0044] Gas SO 2 , when the pH value is 4.5, the absorption reaction reaches the end point, and the reaction temperature is 50°C.

[0045] Then sub-cooling to 25 ° C, stirring speed 40 rpm, to control the formation rate of crystal nuclei and crystal growth rate, so that when the content of potassium bisulfite in the solution reaches the supersaturated concentration, potassium pyrosulfite crystals are precipitated. A slurry containing potassium metabisulfite was obtained.

[0046] (2) Centrifuging the potassium metabis...

Embodiment 2

[0049] (1) Form a solution with tap water and potassium hydroxide ingredients, wherein the solution contains K + 300g / L, add impurity remover A and auxiliary agent B, preferably, impurity remover A adopts activated carbon, auxiliary agent B adopts modified diatomite, and the weight ratio of activated carbon to modified diatomite is 1:1. A clear solution was obtained by filtering through a microporous filter device with a pore size of 0.1 μm.

[0050] Liquid SO 2 , when the pH value is 3.2, the absorption reaction reaches the end point, and the reaction temperature is 42°C.

[0051] Then sub-cooling to 15°C, stirring at a speed of 30 rpm, to control the formation rate of crystal nuclei and the growth rate of crystals, so that when the content of potassium bisulfite in the solution reaches a supersaturated concentration, potassium pyrosulfite crystals are precipitated. A slurry containing potassium metabisulfite was obtained.

[0052] (2) centrifuging the potassium metabisulf...

Embodiment 3

[0055] (1) Potassium metabisulfite mother liquor potassium hydroxide batching is used to form a solution, wherein K is contained in the solution + 100g / L, add impurity remover A and auxiliary agent B, preferably, impurity remover A adopts activated carbon, auxiliary agent B adopts modified diatomite, and the weight ratio of activated carbon to modified diatomite is 1:2, and then Filter through a microporous filter device with a pore size of 10 μm to obtain a clear solution.

[0056] Gas SO 2 , when the pH value is 2.0, the absorption reaction reaches the end point, and the reaction temperature is 80°C. Then sub-cooling to 25 ° C, stirring speed 40 rpm, to control the formation rate of crystal nuclei and crystal growth rate, so that when the content of potassium bisulfite in the solution reaches the supersaturated concentration, potassium pyrosulfite crystals are precipitated. A slurry containing potassium metabisulfite was obtained.

[0057] (2) Centrifuging the potassium m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com