Titanium material, preparation method and application of nano-hydroxyapatite grown in situ on the surface

A nano-hydroxyapatite, in-situ growth technology, applied in chemical instruments and methods, metal material coating technology, tissue regeneration, etc., can solve problems such as thermal expansion coefficient and elastic modulus mismatch, poor bonding strength, etc. Achieve the effect of controllable uniformity, controllable thickness and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

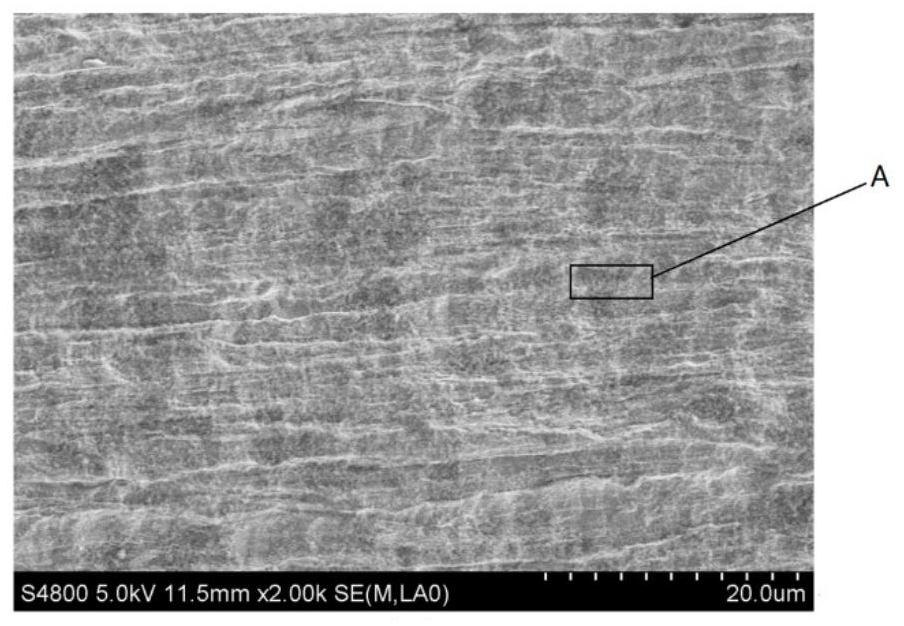

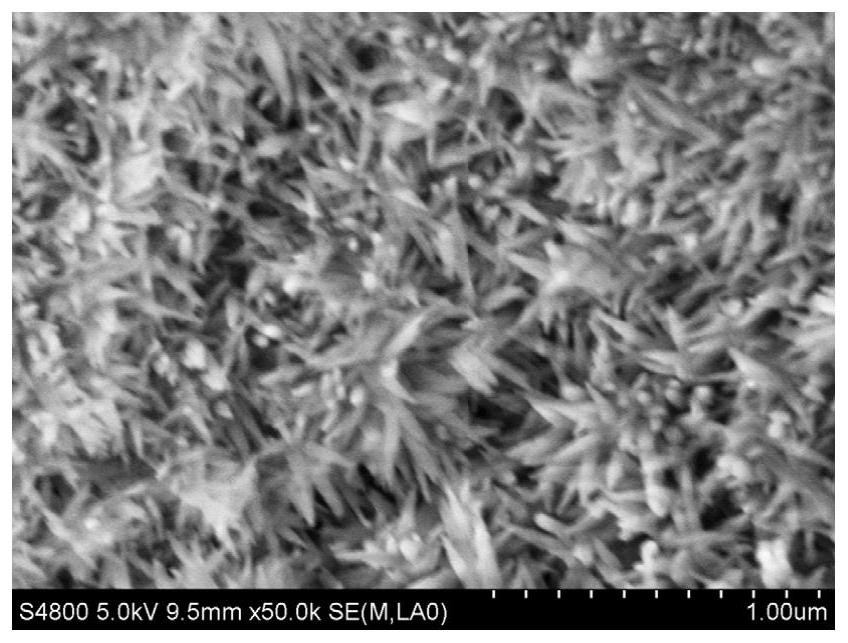

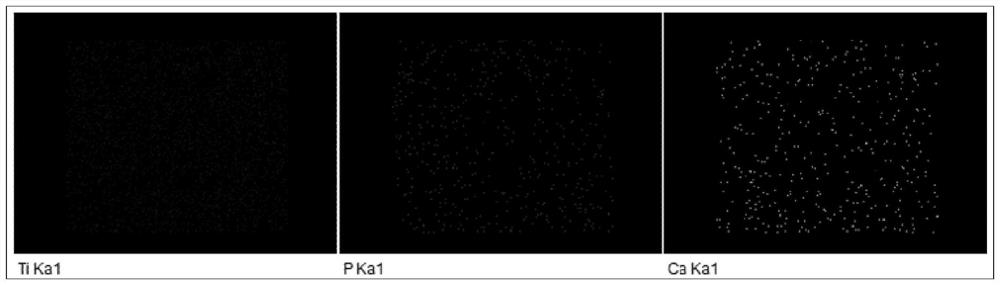

[0059] This embodiment discloses the preparation method of the titanium material with in-situ growth of nano-hydroxyapatite on the surface of the present invention, specifically:

[0060] (1) Cleaning and pretreatment of materials: Cut TA2 pure titanium with filiform crystal topological structure on the surface after rolling and heat treatment into the required structure and size, and use acetone, alcohol, and deionized water for ultrasonication successively Cleaning, each solvent cleaning 30min. Then use 280-1500 mesh sandpaper for grinding, after grinding, clean it again with the above cleaning steps, and then dry it. After the sample is dried, place it in an acid mixture consisting of 5% nitric acid, 3% hydrofluoric acid and 92% deionized water by volume and mass, and ultrasonically clean it for 30 seconds, then wash it with deionized water for 5 minutes, and repeatedly wash it with mixed acid and deionized water. Wash with water 3 times and finally dry.

[0061] (2) Asse...

Embodiment 2

[0071] This embodiment discloses the preparation method of the titanium material with in-situ growth of nano-hydroxyapatite on the surface of the present invention, specifically:

[0072] (1) Cleaning and pretreatment of materials: The surface of TA2 pure titanium will be etched with a femtosecond laser to form a material with a groove depth of 1 micron, a width of 1 micron at the top of the groove, and a 90° angle between the ridge and the bottom of the groove. Then cut into the required structure and size, and use acetone, alcohol, and deionized water to clean ultrasonically, each solvent is cleaned for 30 minutes. Then use 280-1500 mesh sandpaper for grinding, and then clean it according to the above cleaning steps after grinding. After the sample is dried, put it in an acid mixture composed of 8% nitric acid, 7% hydrofluoric acid and 85% deionized water by volume and mass, and ultrasonically clean it for 20s, then wash it with deionized water for 5min, and repeatedly wash ...

Embodiment 3

[0083] This embodiment discloses the preparation method of the titanium material with in-situ growth of nano-hydroxyapatite on the surface of the present invention, specifically:

[0084] (1) Cleaning and pretreatment of materials: Cut the TA2 pure titanium with a filamentous crystal topological structure on the surface after rolling and heat treatment into the required structure and size, and perform ultrasonic cleaning with acetone, alcohol, and deionized water successively. Clean with each solvent for 30 minutes; then polish with 280-1500 mesh sandpaper, and then clean again according to the above cleaning steps. After the material is dried, place it in an acid mixture composed of 8% nitric acid, 5% hydrofluoric acid and 87% deionized water by volume and mass, and ultrasonically clean it for 40 seconds, then wash it with deionized water for 5 minutes, and repeatedly wash it with mixed acid, deionized water, etc. Rinse with deionized water 3 times, and finally dry.

[0085]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com