Method of manufacturing high ventilating adsorption lining paper

A manufacturing method and high-permeability technology, applied in the field of paper manufacturing, can solve the problems of low wet strength, various diseases, local temperature rise, etc., and achieve the effects of uniform adsorption, good air permeability and high wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

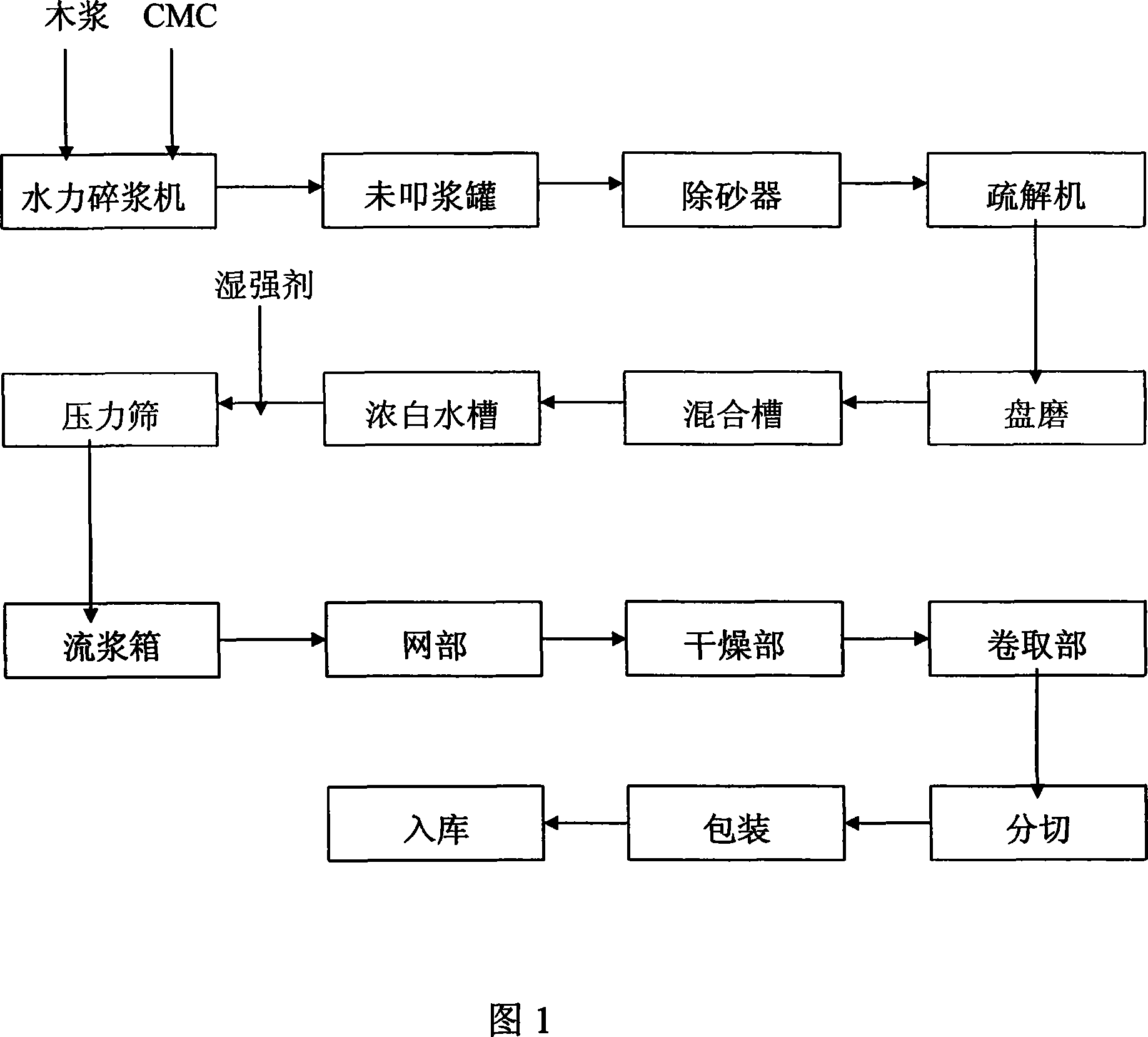

Image

Examples

Embodiment 1

[0011] A method for manufacturing highly air-permeable adsorption backing paper, using natural wood pulp as raw material, including the steps of pulping, desanding, flaking, papermaking, etc., said wood pulp is composed of softwood pulp and hardwood pulp, wherein Coniferous pulp accounts for 80% by weight, hardwood pulp accounts for 20% by weight, and the beating current is 320-340A; the pulp is disintegrated in a hydropulper for 15 minutes, and diluted to a concentration of 3-5% , pumped into the unknocking pulp tank to remove sand, and then into the defiberizing machine for desilting. The decompressed wood pulp enters the double disc mill. After cutting and brooming the fibers, it enters the thick white water tank and is diluted with white water. The slurry goes through the concentrated white water tank to the pressure screen to remove the larger impurities, and finally enters the headbox for online copying, and the concentration of the online copying is 0.05%. Wet strength ...

Embodiment 2

[0013] The present invention is to take bleached wood pulp as production raw material, according to the weight ratio of 90% coniferous pulp: 20% broadleaf pulp is dropped into in the hydraulic pulper, carries out pulping (hydraulic pulper volume is 8m 3 ), adding defoamer at the same time of pulping, adding 250ml per ton of paper, and adding CMC consumption according to 1.5kg / ton of paper; after disintegrating in a hydropulper for 15 minutes, dilute to a concentration of 3-5%. Pumped to the intermediate slurry tank (32m 3 ), and then use the intermediate pump to pump to the uncracked slurry tank (32m 3 ), desanding by high-concentration desander to remove impurities with large proportions such as sand and iron in the raw material; the slurry enters the deflagging machine from the unbeaten pulp, and fully decomposes the fibers, so that the fibers can be fully divided into filaments ;The decomposed wood pulp enters the ¢550mm double disc mill to cut and broom the fibers; after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com