High-frequency and high-speed PCB polishing device with automatic cleaning function

An automatic cleaning and functional technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of recovery and cleaning of difficult air extraction structures, impurities flying around, pollution on the processing site, etc., so as to improve the grinding efficiency , reduce pollution, simplify the effect of the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

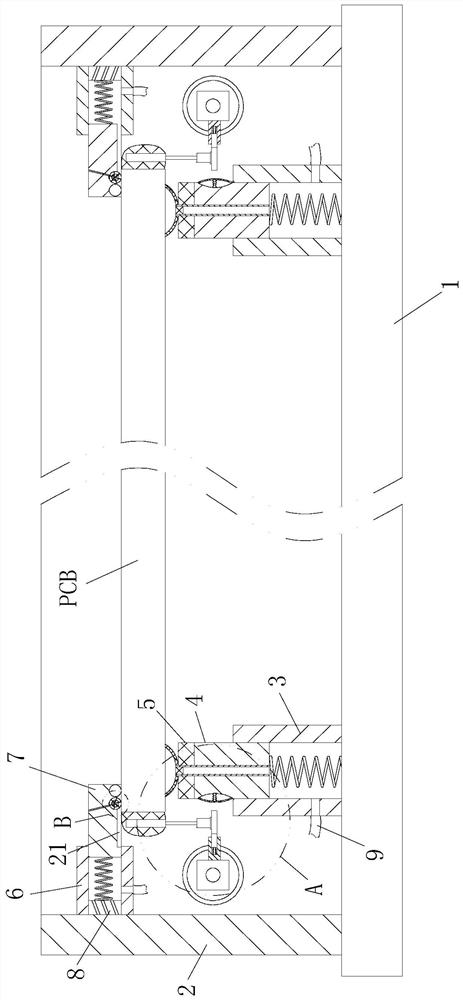

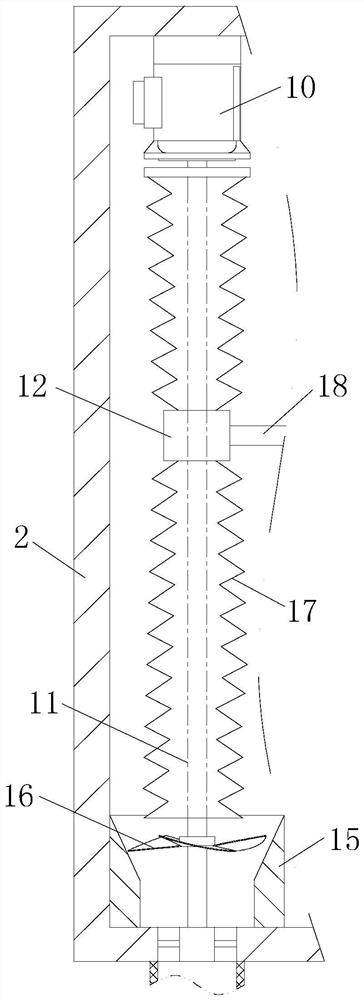

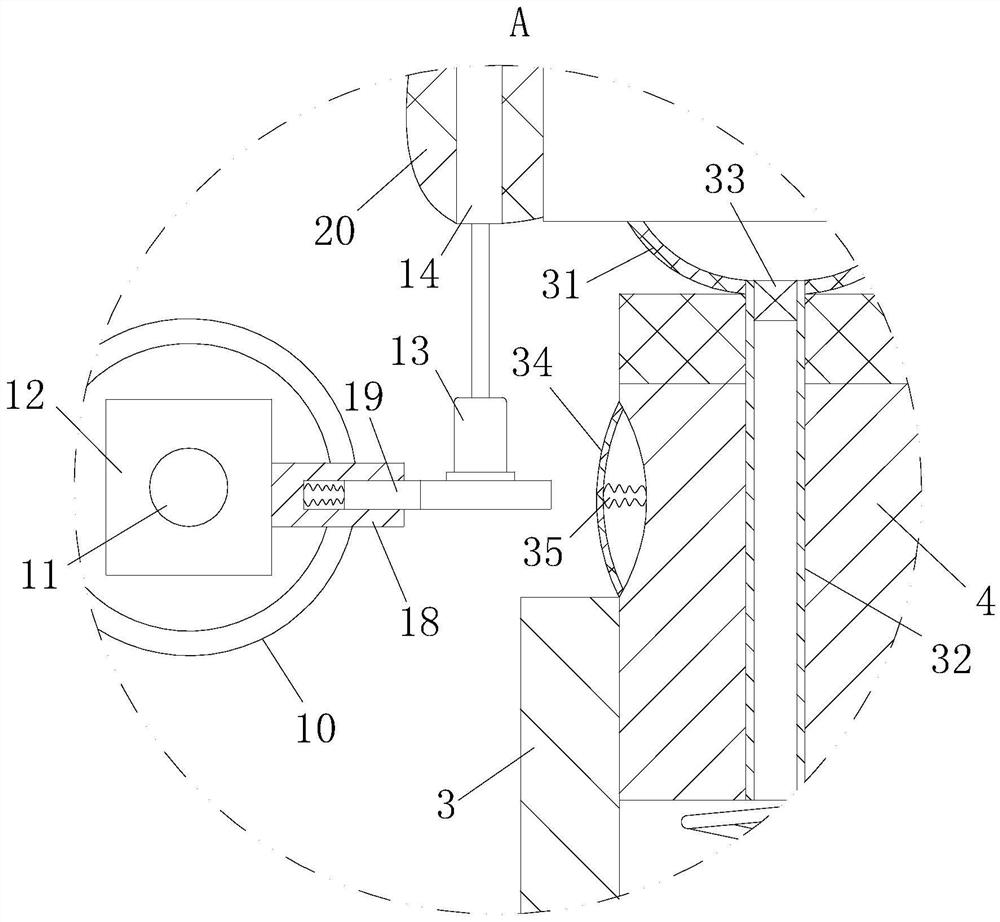

[0030] see Figure 1-Figure 4 As shown, a high-frequency and high-speed PCB polishing device with automatic cleaning function described in the embodiment of the present invention includes a support plate 1; two sets of baffle plates 2 are symmetrically connected to the support plate 1, and the support plate 1 is close to The top surface of the baffle plate 2 is symmetrically provided with a slide chamber 3, the top of the slide chamber 3 is slidably connected with a slide plate 4 that fits the inner wall, the top of the slide plate 4 is connected with an elastic layer 5, and the slide plate 4 is connected to the slide plate 4. There is a No. 1 spring connected between the bottom ends of the cavity 3, and a support cavity 6 is connected to the side wall of the baffle plate 2 corresponding to the top side of the sliding cavity 3, and the inside of the support cavity 6 is slidably connected to fit the inner wall. The limiting plate 7, the No. 2 spring is connected between the lim...

Embodiment 2

[0040] Such as Figure 5 As shown in Comparative Example 1, another embodiment of the present invention is: an arc-shaped sleeve 36 is embedded in the nozzle hole, and a gap is opened on the side of the arc-shaped sleeve 36 close to the inner end of the groove. The inside of the arc-shaped sleeve 36 is connected with a cylindrical rotating post 37 through a torsion spring, the side wall of the rotating post 37 fits with the inner wall of the arc-shaped sleeve 36, and the side wall of the rotating post 37 is provided with a gap connected to the air outlet hole 38, the end of the air outlet hole 38 away from the groove is arranged obliquely downward; The pressure will also drive the rotating column 37 to rotate by applying frictional resistance to the rotating column 37, so that the gas inside the groove is ejected in a rotating manner from the rotating air outlet hole 38, thereby increasing the cleaning area of the eardrum 34 for impurities. Further promote the recovery of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com