A high-frequency and high-speed pcb grinding device with automatic cleaning function

An automatic cleaning and functional technology, applied in grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve the problems of flying impurities, pollution on the processing site, recycling and cleaning of difficult-to-pump structures, etc., to improve grinding efficiency , the effect of reducing pollution and simplifying the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

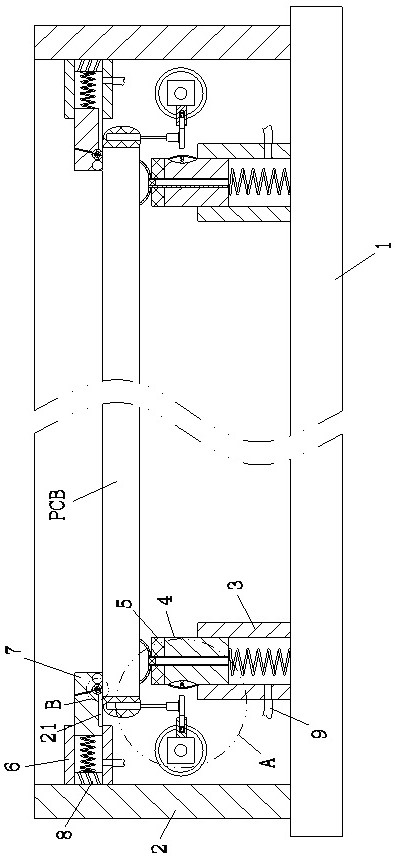

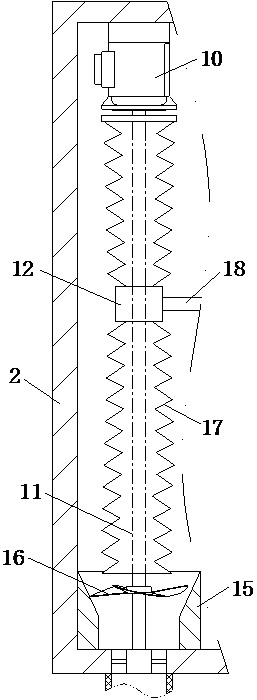

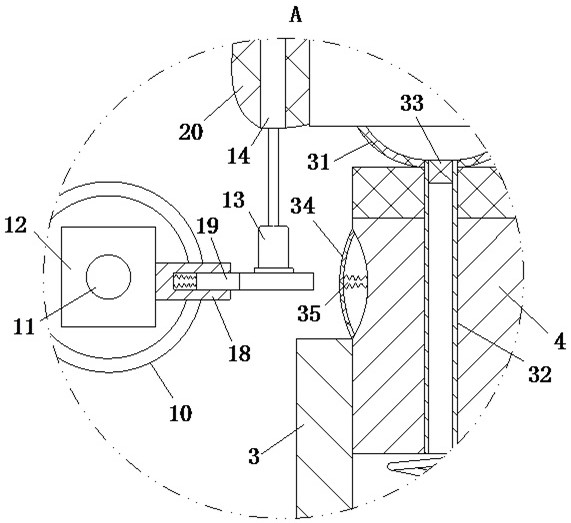

[0028] see Figure 1-Figure 4 As shown in the figure, a high-frequency and high-speed PCB grinding device with automatic cleaning function according to the embodiment of the present invention includes a support plate 1; two sets of baffles 2 are symmetrically connected on the support plate 1, and the support plate 1 is close to the A sliding cavity 3 is symmetrically arranged on the top surface of the baffle 2, the top of the sliding cavity 3 is slidably connected with a sliding plate 4 that fits with its inner wall, the top of the sliding plate 4 is connected with an elastic layer 5, and the sliding plate 4 is connected with the sliding plate 4. A No. 1 spring is connected between the bottom end of the cavity 3, a support cavity 6 is connected to the side wall of the baffle plate 2 corresponding to the top side of the sliding cavity 3, and the support cavity 6 is slidably connected to the inner wall of the support cavity 6. The limit plate 7 is connected with a No. 2 spring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com