Whisker strengthening toughening halogen-free flame retardance phenolic aldehyde foamed plastic and preparation method thereof

A phenolic foam plastic, strengthening and toughening technology, applied in the field of polymer thermal insulation material preparation, can solve the problem that strength and toughness cannot be both, and achieve the effects of reducing slag removal rate, maintaining excellent performance and improving fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

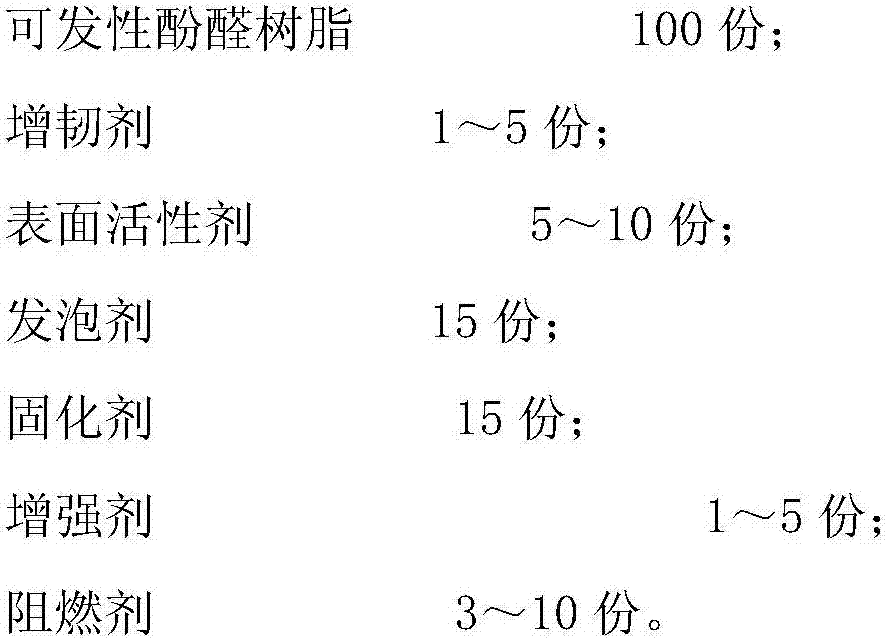

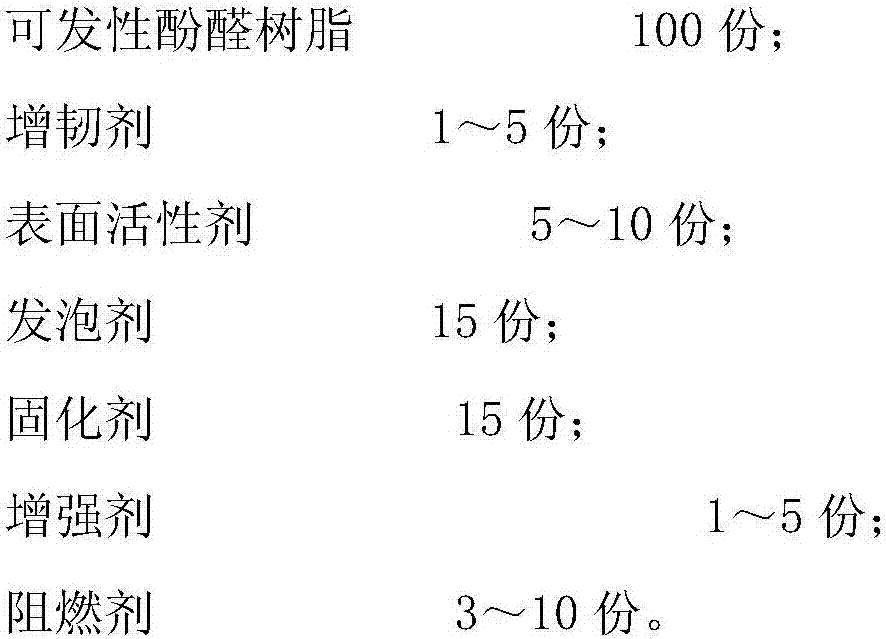

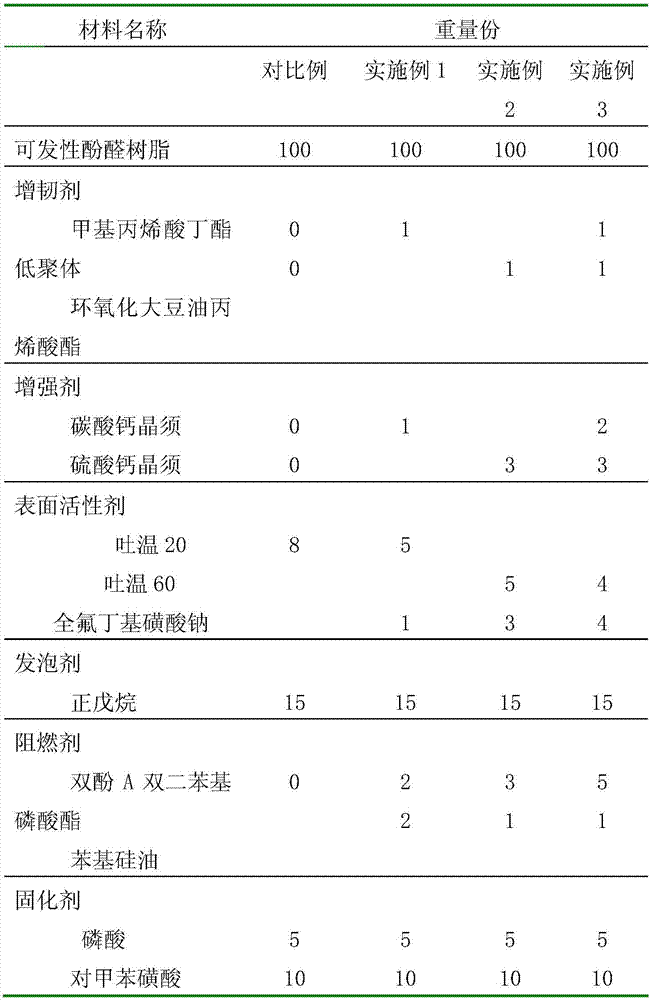

Method used

Image

Examples

preparation example Construction

[0022] An embodiment of the present invention provides a method for preparing whisker-reinforced and toughened halogen-free flame-retardant phenolic foam, which is used to prepare the above-mentioned whisker-reinforced and toughened halogen-free flame-retardant phenolic foam, comprising the following steps:

[0023] Get and prepare each component of whisker-reinforced and toughened halogen-free flame-retardant phenolic foamed plastics according to the above-mentioned formula;

[0024] Preheat the expandable phenolic resin to 30-40°C, add toughening agent, surfactant, flame retardant, reinforcing agent and foaming agent, stir for 10-30 minutes under the action of ultrasonic waves, then add curing agent and stir evenly for 10 minutes Minutes, then quickly pour into the mold, foam and solidify at 70-90°C for 1-3 hours to obtain whisker-reinforced and toughened halogen-free flame-retardant phenolic foam.

[0025] In the above method, the dispersibility of components such as whiske...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com