Fuel heater

A fuel heater and fuel technology, which is applied to heating/cooling equipment, machines/engines, air handling equipment, etc., can solve the problems of uneven intake air distribution, large flue gas flow resistance, and easy generation of flocculation, and achieve improvement. Vaporization ignition conditions and combustion conditions, improving the utilization rate of heat, and improving the effect of ignition conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

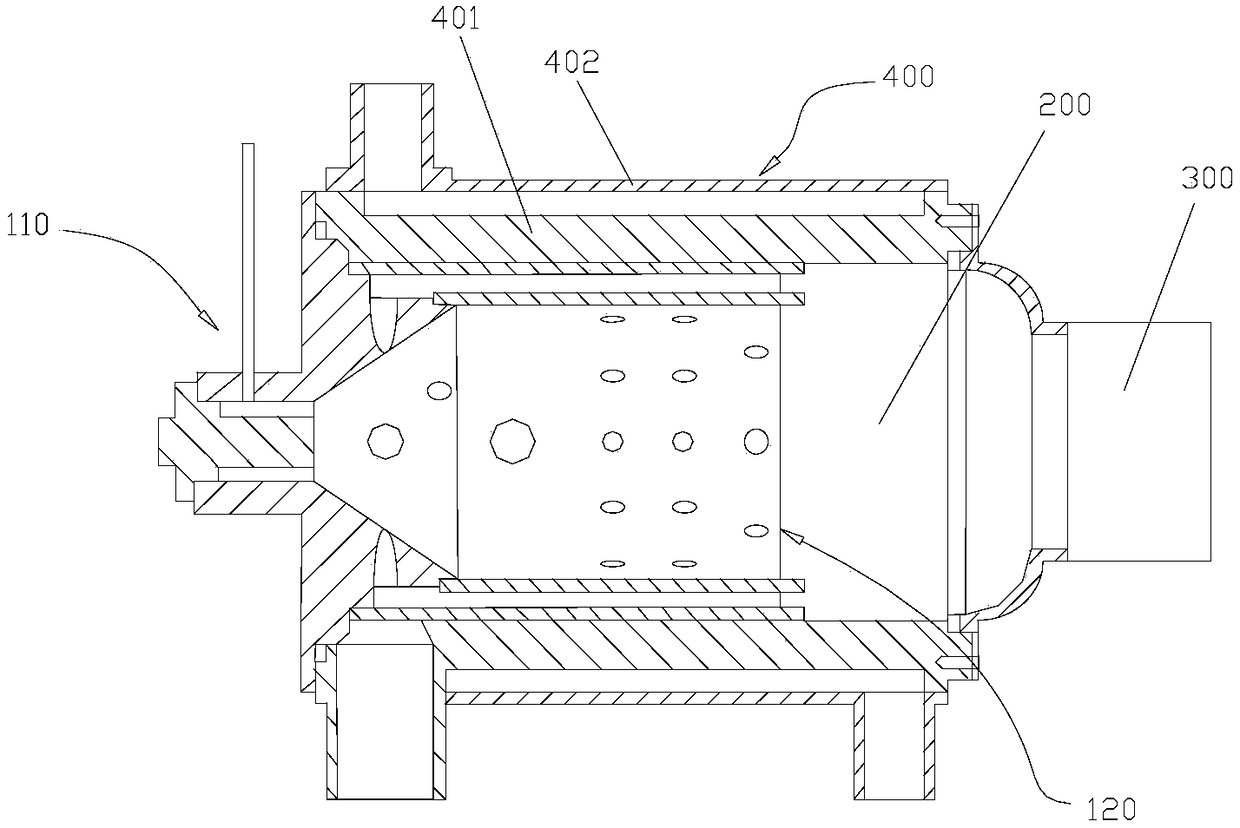

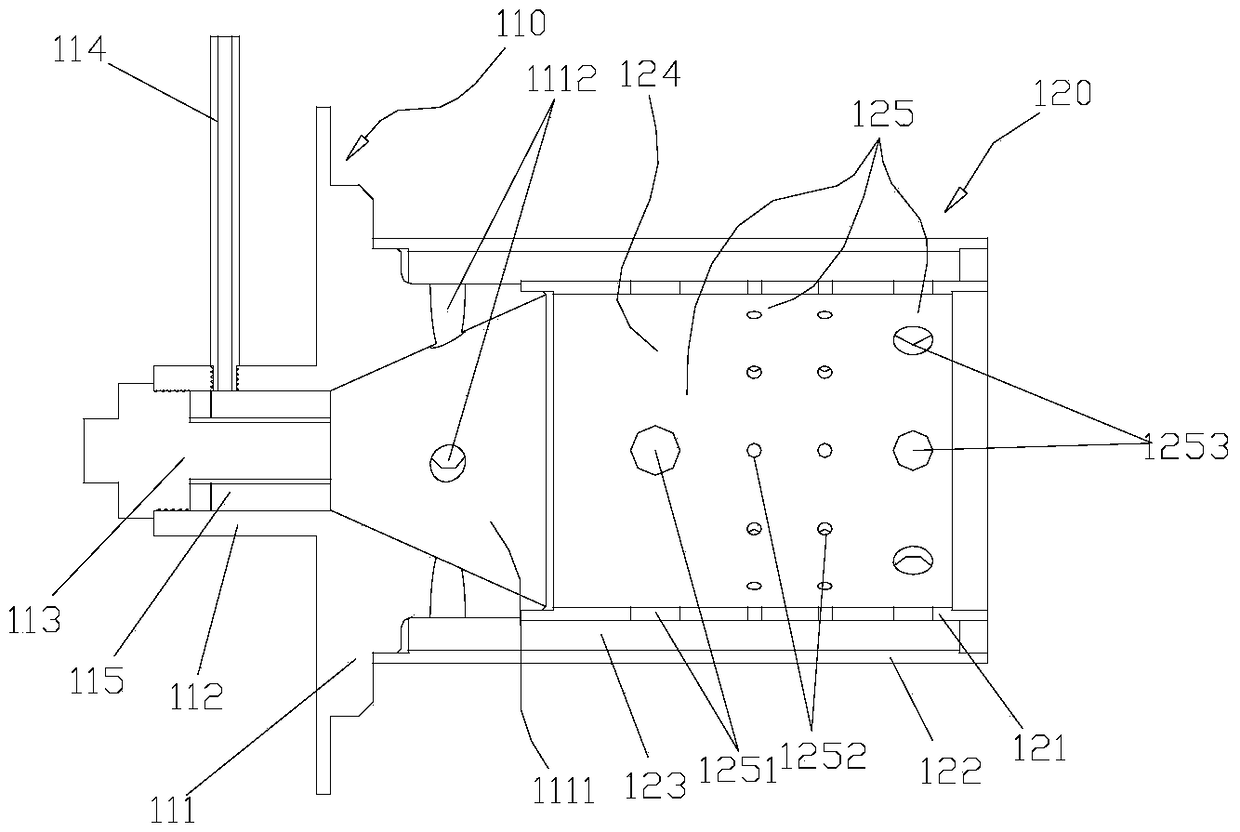

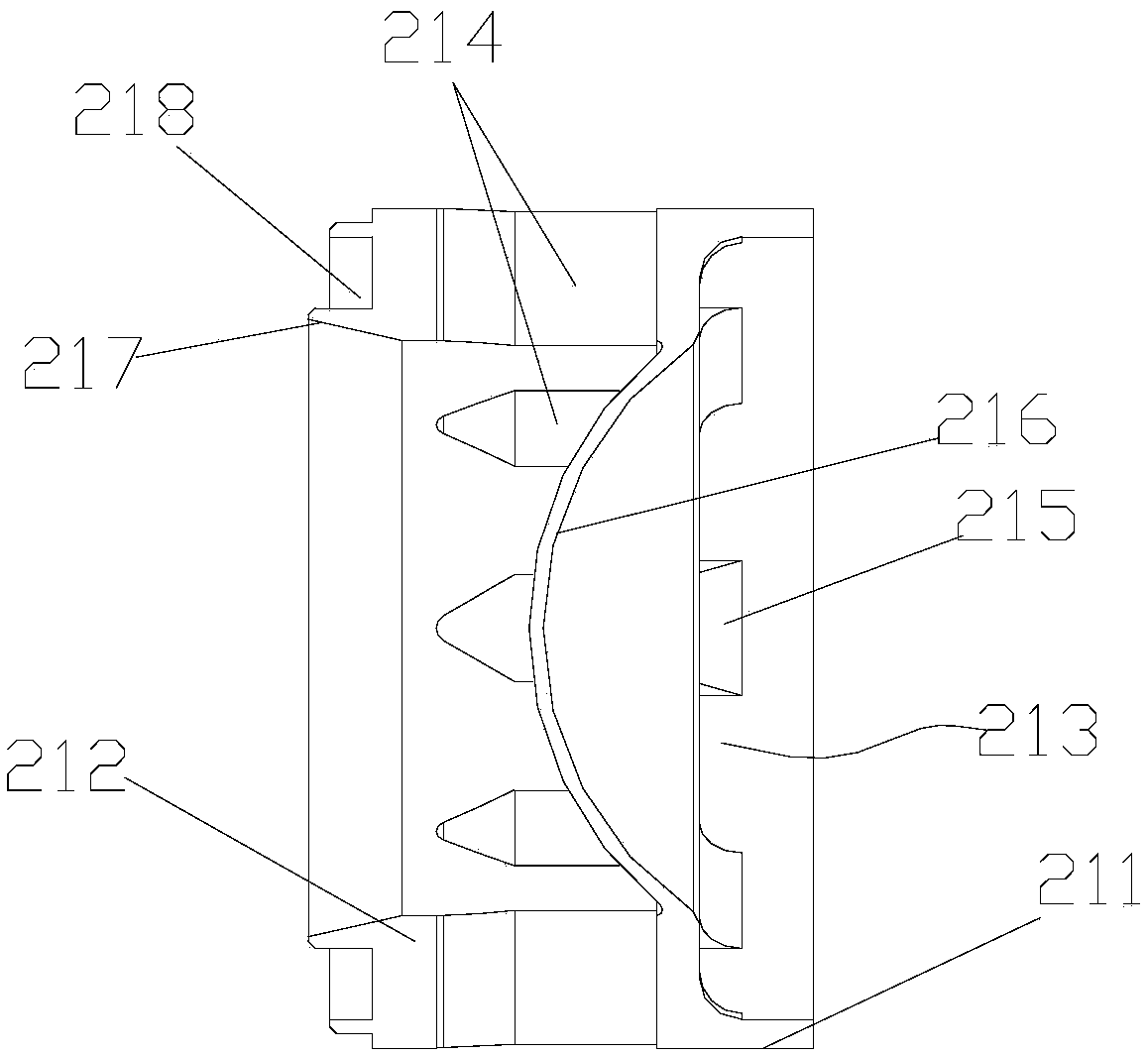

[0047] Such as figure 1 and figure 2 As shown, the embodiment of the present invention discloses a fuel heater, which includes a vaporization mechanism 110 , a combustion mechanism 120 , an air blowing mechanism 300 and a heat exchange mechanism 400 . The combustion mechanism 120 has a combustion chamber 124, the vaporization mechanism 110 is used to provide vaporized fuel for the combustion chamber 124 so that the fuel is combusted in the combustion chamber 124; the blower mechanism 300 is used to provide air for the combustion chamber 124 and the vaporization mechanism 110; the heat exchange mechanism 400 is used to export the heat generated by fuel combustion. Wherein: the combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com