Manufacturing method of insulated gate bipolar transistor (IGBT)

A technology of bipolar transistors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as complex processes, achieve the effect of suppressing diffusion efficiency and improving turn-off rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

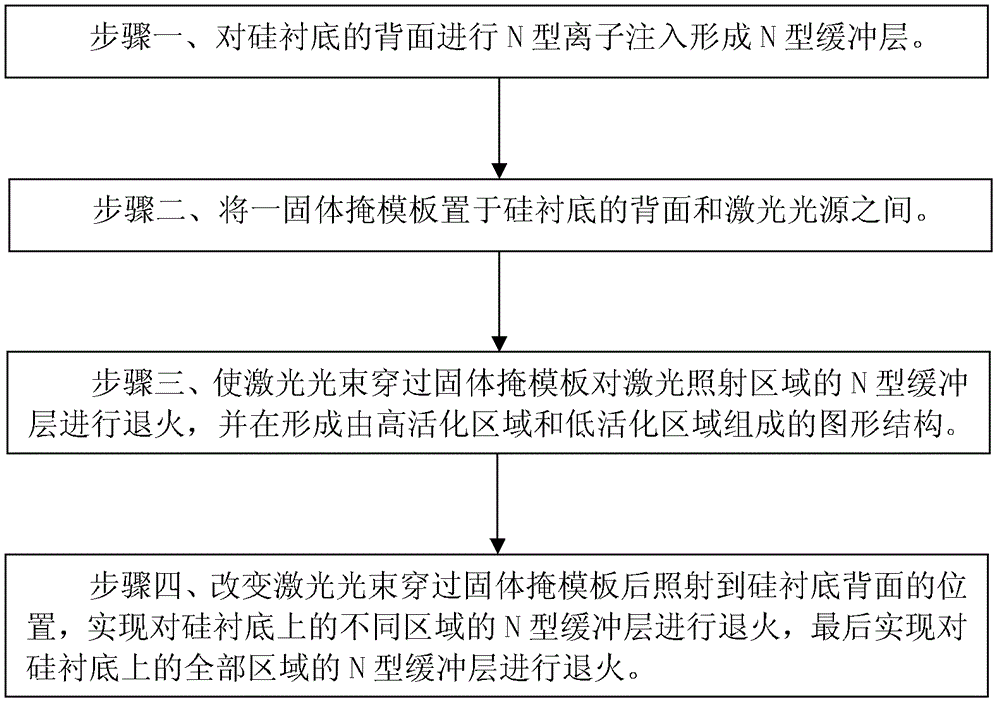

[0032] Such as image 3 Shown is a flow chart of the manufacturing method of the IGBT of the embodiment of the present invention. The manufacturing method of the IGBT of the embodiment of the present invention comprises the following steps:

[0033] Such as Figure 4 As shown, the front side process of the insulated gate bipolar transistor is first carried out on the silicon substrate.

[0034] The front process includes the following steps:

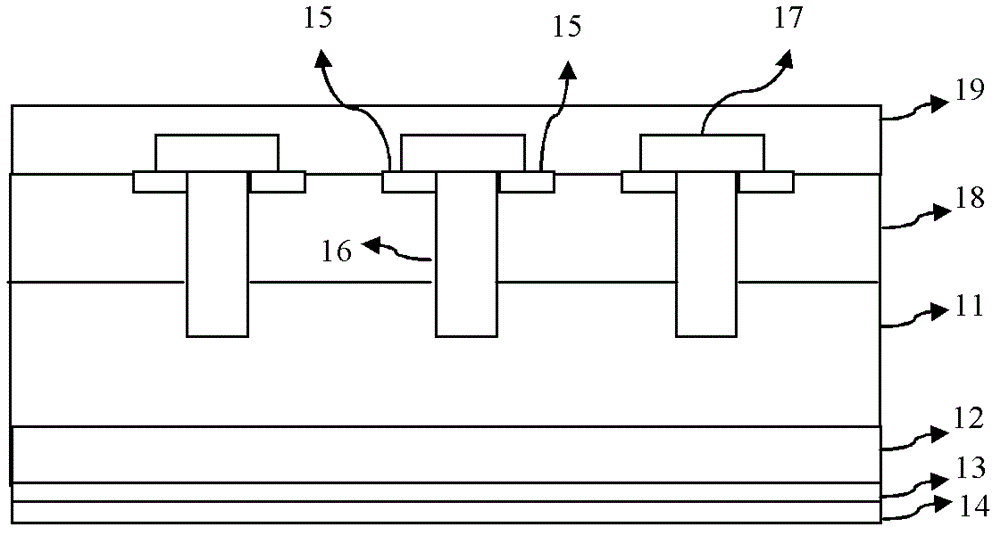

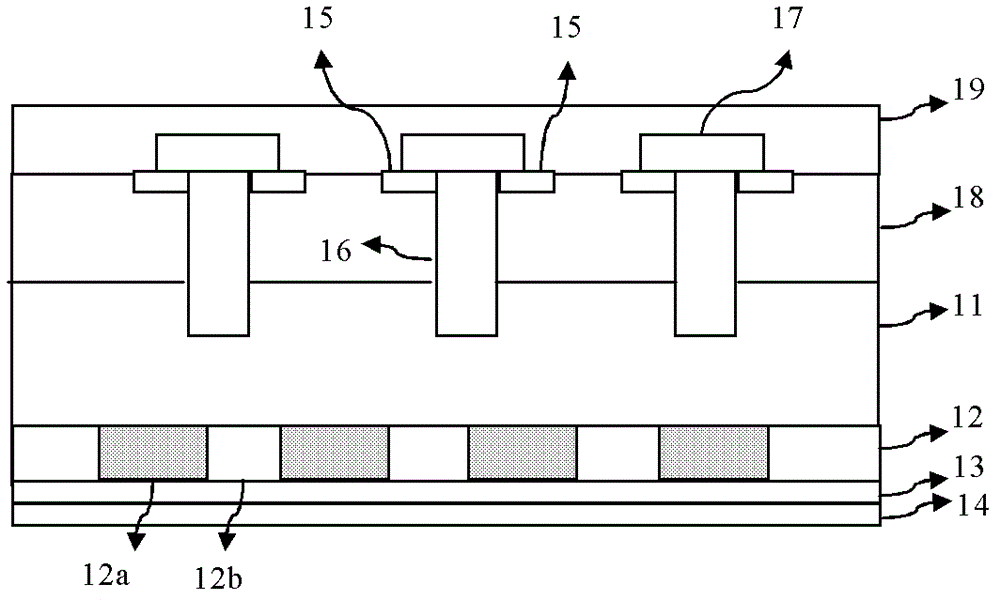

[0035] An N-type drift region 11 is formed on the silicon substrate.

[0036] A P-type base region 18 is formed on the N-type drift region 11 .

[0037] A deep trench is formed on the silicon substrate, and polysilicon is filled in the deep trench to form a gate 16 . The gate 16 passes through the P-type base region 18 and enters into the N-type drift region 11 .

[0038] N-type ion implantation is performed in the P-type base region 18 on both sides of the gate 16 to form an N+ doped emitter region 15 . The gate 16 covers the P-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com