Pulverized coal combustion process in annular lime kiln and application thereof

A pulverized coal combustion and annular sleeve technology, which is applied in the field of pulverized coal combustion technology, can solve the problems that the sleeve kiln cannot continue to produce, the refractory material has strong corrosion, and it is easy to form slagging in the combustion chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

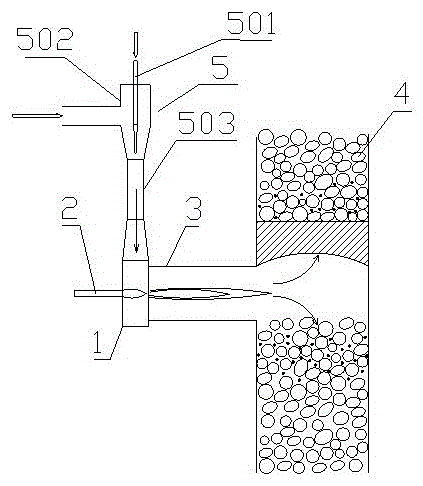

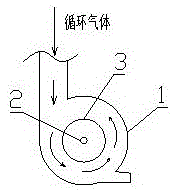

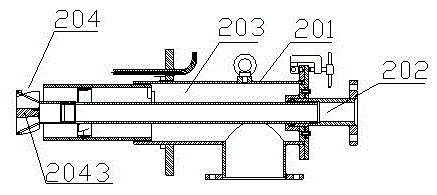

[0026] In the present embodiment, an annular sleeve kiln calcining limestone is used as an example to illustrate a pulverized coal combustion process in an annular sleeve kiln. Entering the volute 1 from the tangential direction to form a circumferential swirling wind, the pulverized coal composed of volatile matter and fixed carbon is ejected from the outlet of the pulverized coal passage of the pulverized coal burner 2 and encounters high temperature circulating gas in the volute 1. The center of the swirl wind formed by the circulating gas is rapidly preheated, dried and ignited. At this time, the oxygen involved in the combustion comes from the combustion-supporting air of the pulverized coal burner and the pulverized coal conveying air. 10% of the air volume (volume fraction), the pulverized coal is burned under oxygen-deficient fuel-rich conditions; (2), the pulverized coal volatiles are burned in the combustion chamber 3: the pulverized coal enters the combustion chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com