Self-checking circuit, self-checking method and self-checking system for photosensitive element as well as air conditioner

A technology of photosensitive devices and self-test circuits, applied in heating and ventilation control systems, heating and ventilation safety systems, instruments, etc., can solve problems such as lowering equipment reliability, low brightness, and violation of intelligent design, and achieve simple processing, Avoid false control and facilitate the effect of controlling the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

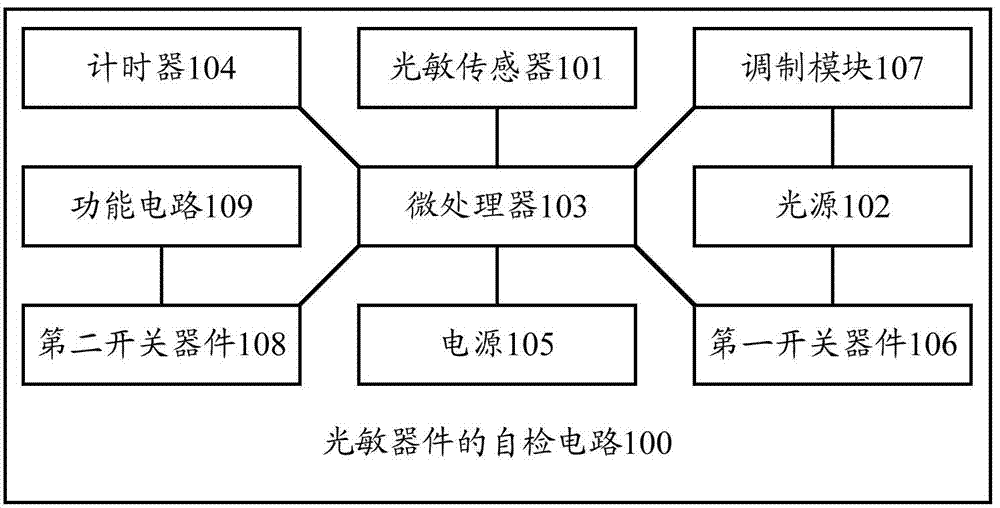

[0066] like figure 1 As shown, the photosensitive device self-test circuit 100 according to the embodiment of the present invention includes: a photosensitive sensor 101; A detection light source 102 is provided to the photosensitive sensor 101 in the middle; a microprocessor 103, connected to the light source 102, is used to realize the self-test process of the photosensitive device by controlling the light source 102 to be turned on.

[0067] According to the self-checking circuit of the photosensitive device according to the embodiment of the present invention, by arranging the light source 102 in the photosensitive device to provide the detection light source 102 to the photosensitive sensor 101, the self-checking process of the photosensitive device is realized, so as to conveniently judge whether the photosensitive device is working effectively, and in addition , to judge the reliability of the photosensitive device in time, so that the microprocessor 103 can accurately ...

Embodiment 2

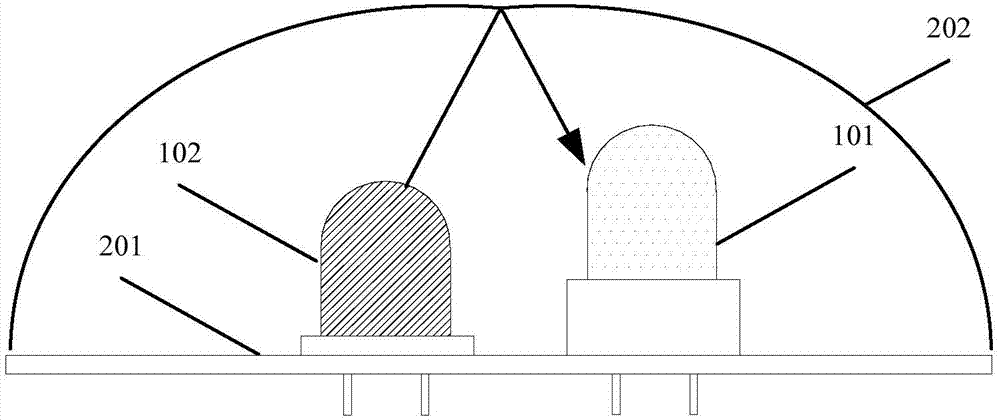

[0086] like figure 2 As shown, the photosensitive device self-checking circuit according to the embodiment of the present invention includes: fixing the light source 102 and the photosensitive sensor 101 on the PCB substrate 201, after the light source 102 is turned on, the light is reflected to the photosensitive sensor 101 through the panel 202, wherein, in order to In order to reduce the loss during the operation of the light source, an anti-reflection coating can be provided in the reflection area of the panel 202. Specifically, the anti-reflection processing is performed for the wavelength band of the light source, without affecting the sensing of the ambient light outside the panel 202 by the photosensor 101. In addition, in order to enhance the photosensitive characteristics of the photosensitive sensor 101, the skirt of the photosensitive sensor 101 is increased, or the height of the fixing base of the photosensitive sensor 101 is increased.

Embodiment 3

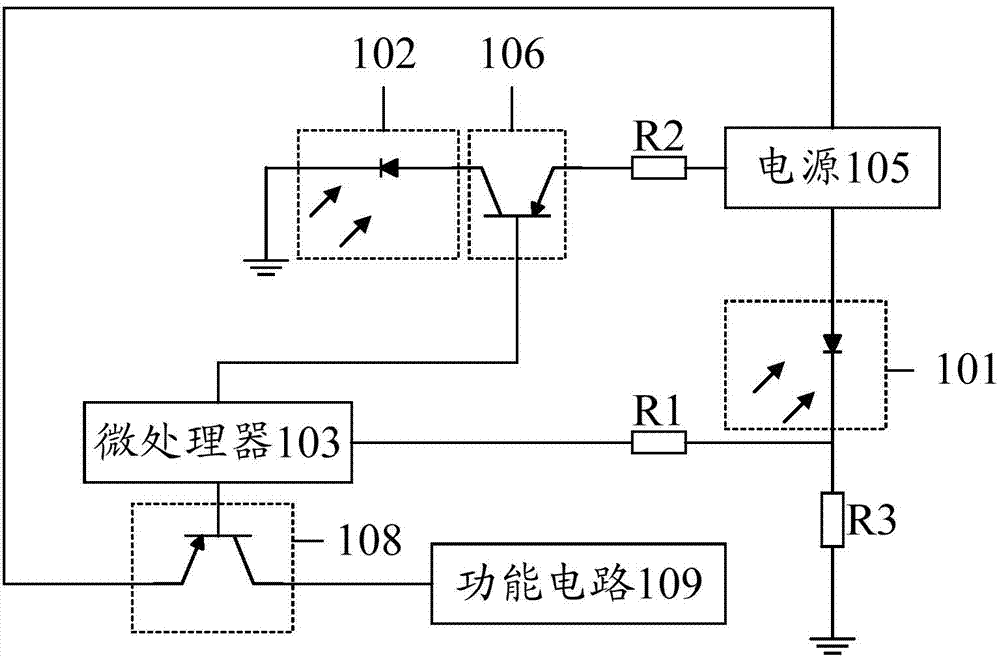

[0088] like image 3 As shown, the photosensitive device self-checking circuit according to the embodiment of the present invention includes: taking the microprocessor 103 as the core component, controlling the opening and closing of the light source 102 through the first switching device 106, and the other side of the first switching device is connected to to the resistor R2 and the power supply 105, wherein the power supply 105 is also used to provide a working voltage to the second switching device 108 and the photosensor 101, and the second switching device 108 is used to control the working state of the functional circuit 109 according to the instruction of the microprocessor 103, Among them, R1 and R3 are used to perform voltage division processing on the output voltage of the photosensitive sensor 101, and send the voltage after voltage division processing to the microprocessor for calculation and control.

[0089] like Figure 4 to Figure 5 As shown, the photosensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com