Self-check method, device and system of high-voltage loop of power battery

A power battery and high-voltage circuit technology, which is applied in the field of self-inspection of the high-voltage circuit of the power battery, can solve the problems of affecting the service life of the relay, affecting the safety of the whole vehicle, and the safety loopholes of the high-voltage circuit of the power battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

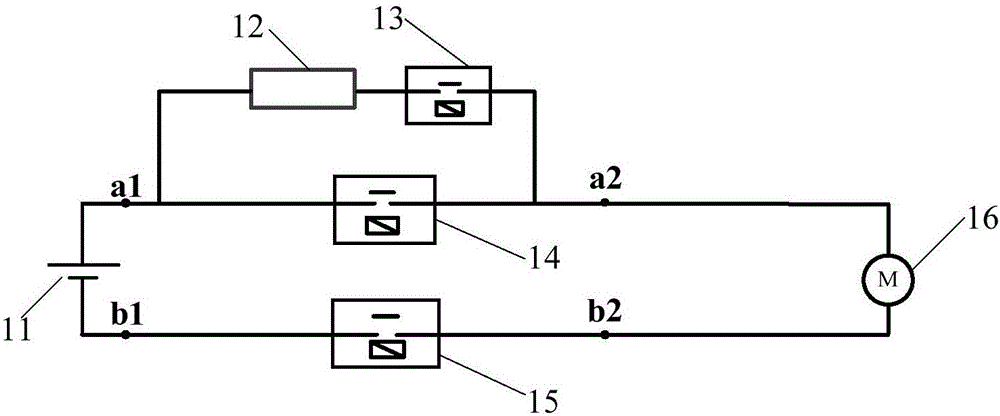

[0070] figure 1 It is a schematic structural diagram of a power battery high-voltage circuit provided by the embodiment of the present application.

[0071] Such as figure 1 As shown, the power battery high-voltage circuit at least includes: a power battery 11; a pre-charging relay 13 connected to the negative pole of the power battery 11 through a pre-charging resistor 12 at one end; A high-voltage main positive relay 14 with one end connected to the other end of the pre-charging relay 13; one end connected to the common end of the pre-charging relay 13 and the high-voltage main positive relay 14, and the other end connected to the positive pole of the power battery through the high-voltage main negative relay 15 16.

[0072] The above is only the preferred solution of the embodiment of the present application. Specifically, the power battery high-voltage circuit includes but is not limited to include the power battery 11, the pre-charging resistor 12, the pre-charging rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com