Grid plate beam uniform air supply structure

A grate plate and air supply technology is applied in the field of uniform air supply structure of grate plate beams for cement clinker coolers to achieve the effects of energy saving and reasonable air distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

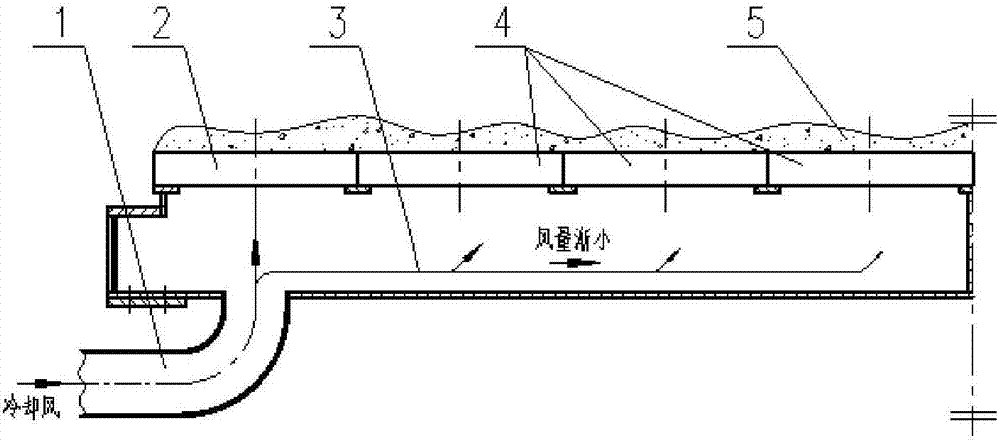

[0015] Such as figure 1 As shown (half of the complete mirror image), in the grate cooler in the cement plant at present, its air supply pipe 1 sends the cold wind sent by the cooling fan to the two ends of the outer sides below the grate beam 3, so that the grate near the air inlet The wind that the side grate plate 2 supplies is more than the middle grate plate 4 far away from the air supply port, and the more the middle grate plate 4 in the middle supplies less wind.

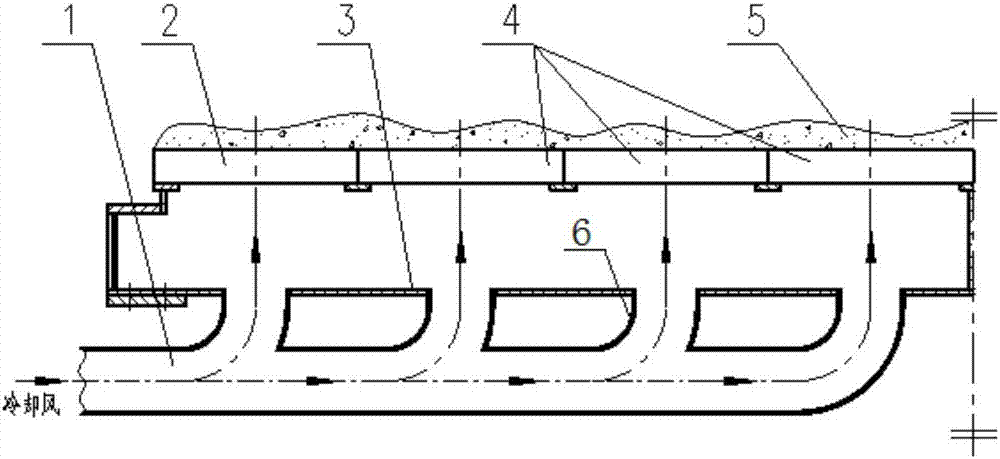

[0016] In order to make all the side grate plates 2 and middle grate plates 4 on the same grate plate beam 3 obtain a uniform air supply, the present invention changes the original single air supply pipe 1 into an air supply pipe in the form of multiple forked pipes. (Such as figure 2 As shown), the air volume of the cooling air can be evened before entering the side grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com