Underfeed type biomass combustion boiler

A biomass and boiler technology, which is applied in the field of down-feed biomass burning boilers and biomass burning boilers, can solve the problems of unreasonable air distribution, prone to back-burning, insufficient combustion, etc. Reasonable and sufficient fuel combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

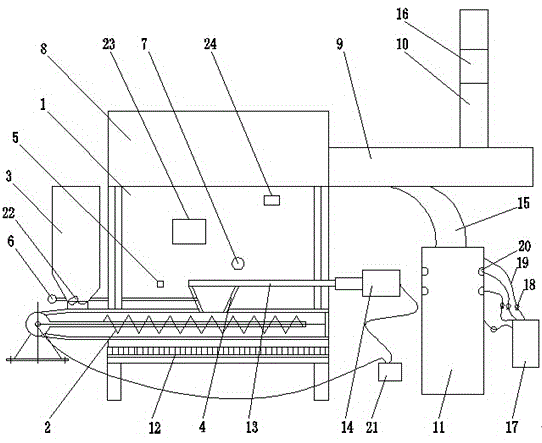

[0029] Specific embodiments: for illustration in conjunction with the accompanying drawings, the feed-down biomass combustion boiler of this embodiment includes a furnace 1, a screw feeder 2 and a feed box 3; the screw feeder 2 is provided with a furnace 1 and a feeder The box 3 and the feed box 3 are located outside the furnace 1; the down-feed biomass combustion boiler also includes a feed tube 4, an automatic igniter 5, a primary air distribution pipe 6, a secondary air distribution pipe 7, a flue 8, and a flue Gas outlet pipe 9, chimney 10, settling chamber 11, support 12, flame retardant plate 13, electric push rod 14, pipeline 15 and induced draft fan 16; Described feeding cylinder 4 is arranged in furnace 1, and feeding cylinder 4 The lower end of the screw feeder 2 communicates with the interior of the screw feeder 2, the primary air distribution pipe 6 passes through the side wall of the furnace 1 and communicates with the feeding cylinder 4, the furnace 1 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com