Secondary combustion chamber air-distribution device of hazardous waste incineration system

A technology of air distribution device and secondary combustion chamber, which is applied to incinerators, combustion types, combustion equipment, etc., can solve the problems of increasing the diameter and height of secondary combustion chambers, increasing installation and maintenance costs, and increasing the distance traveled by flue gas. , to achieve reasonable air distribution, improve combustion effect, and reduce the effect of equipment installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

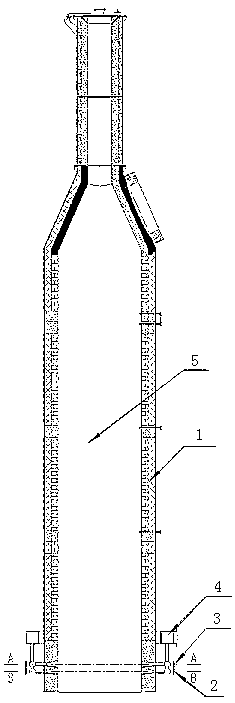

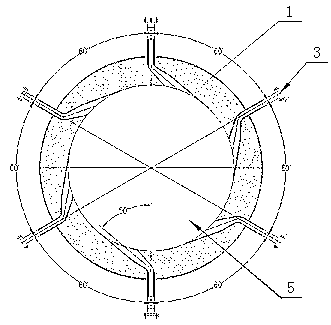

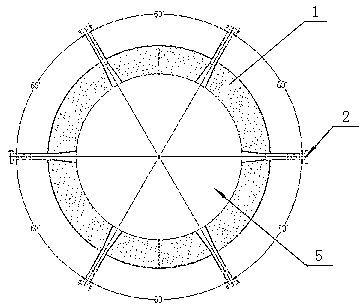

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a secondary combustion chamber 1, the bottom of the secondary combustion chamber 1 is provided with bottom air inlets 2 and upper layer air inlets 3 distributed in upper and lower layers, and the bottom air inlets 2 and upper layer air inlets 3 are respectively evenly distributed in the second combustion chamber 1 There are several of the same cross-section of the furnace wall, the bottom air inlet 2 is perpendicular to the furnace wall of the second combustion chamber 1 and enters the furnace 5 along the radial direction, and the upper layer air inlet 3 is connected to the second combustion chamber 1 in a clockwise direction along the inner wall of the furnace 5 to enter.

[0022] The flue gas produced by incineration is powered by the fan 4 and enters the secondary combustion chamber 1. The structure of the secondary combustion chamber 1 is a vertical hollow cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com