Front-located cation bed cation regenerating column

A pre-cationic bed and cation technology, which is applied in the direction of ion exchange regeneration, ion exchange, ion exchange water/sewage treatment, etc., can solve the problems of inadaptability, frequent regeneration, and insufficient drainage, so as to achieve reasonable air distribution, The effect of uniform collection of waste liquid and high regeneration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

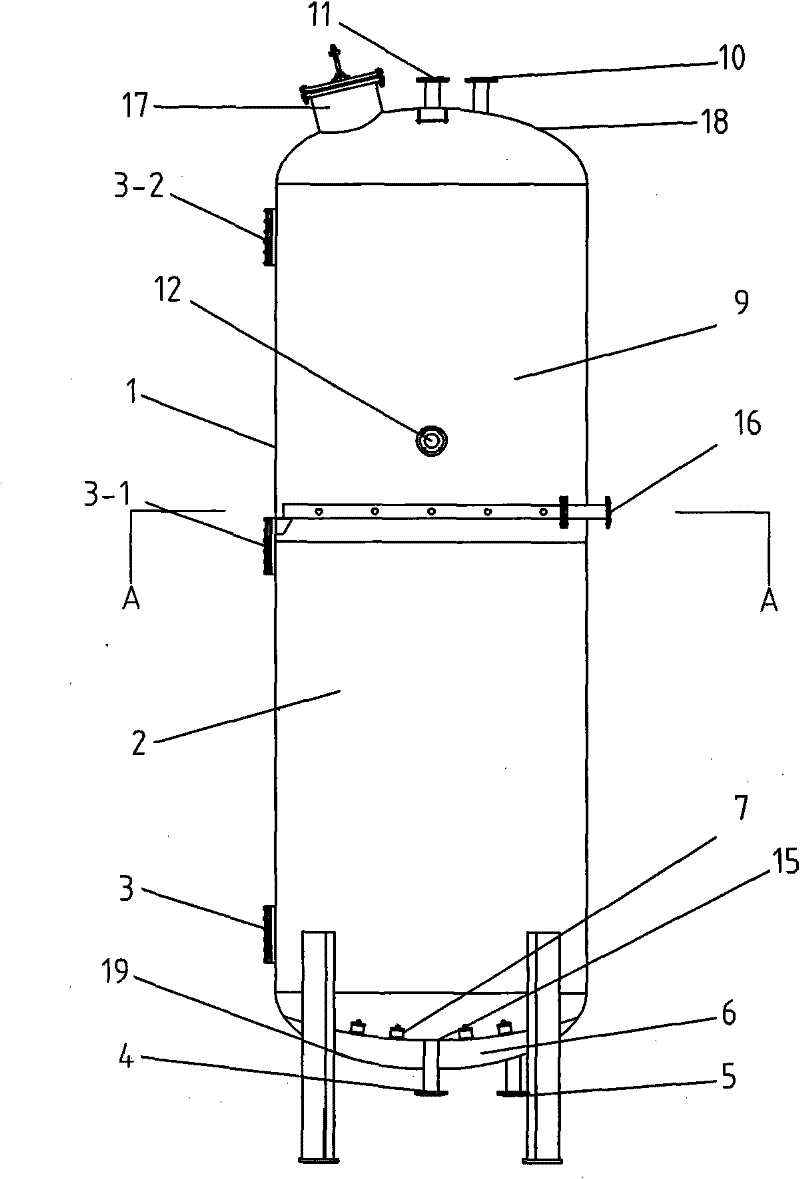

[0023] Embodiment 1: as Figures 1 to 3 As shown, the main body of this embodiment is the housing 1,

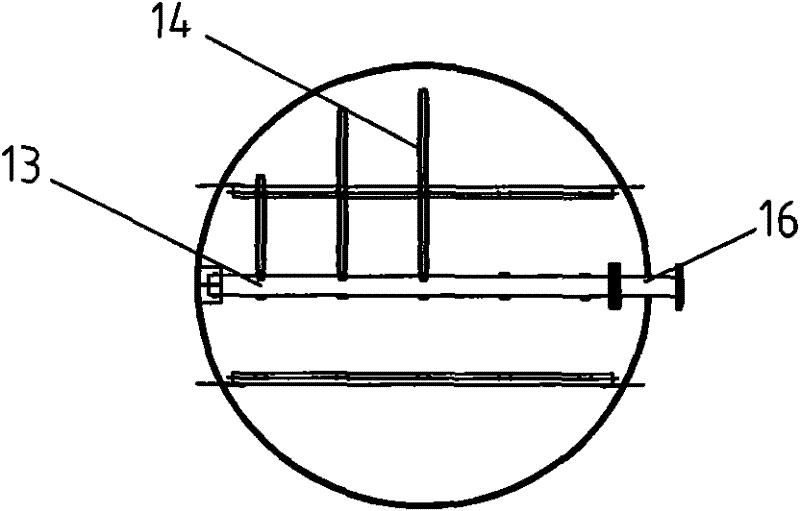

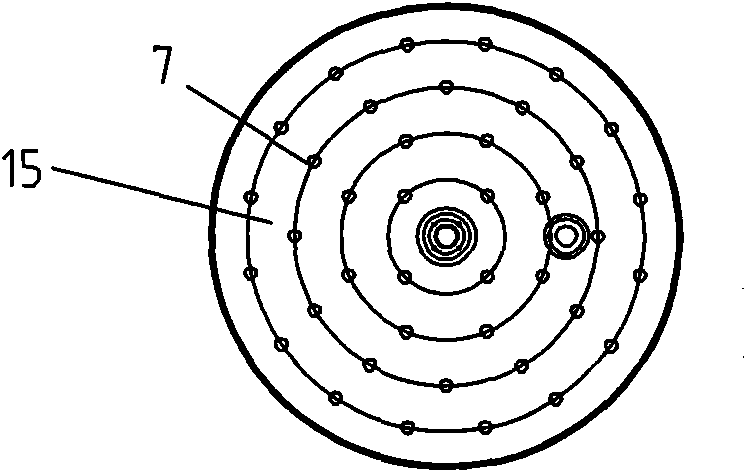

[0024] Shell 1, resin layer 2, lower viewing mirror 3, resin outlet pipe 4, backwash water inlet and outlet 5, bottom distribution device 6, water collection cap 7, distribution and collection device, resin expansion space 9, air inlet and outlet 10, positive Washing water inlet 11, resin inlet 12, main pipe 13, branch pipe 14, spherical orifice plate 15, regeneration liquid inlet and outlet 16, manhole 17, middle viewing mirror 3-1, upper viewing mirror 3-2, upper elliptical head surface 18. The curved surface of the lower ellipse head 19.

[0025] Housing 1 is provided with resin inlet 12, resin outlet pipe 4, air inlet and outlet 10, front washing water inlet 11, backwash water inlet and outlet 5, regeneration liquid inlet and outlet 16, upper peep mirror 3-2, middle peep mirror 3 -1, the lower viewing mirror 3 and the manhole 17. The housing 1 is provided with a distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com