Forward and reverse air distribution structure for biomass burner

A burner and biomass technology, applied in the field of biomass burner air distribution structure, can solve the problems of dead air distribution angle, unreasonable air distribution, insufficient combustion of combustible volatiles, etc., to improve fuel heat utilization rate, air distribution reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

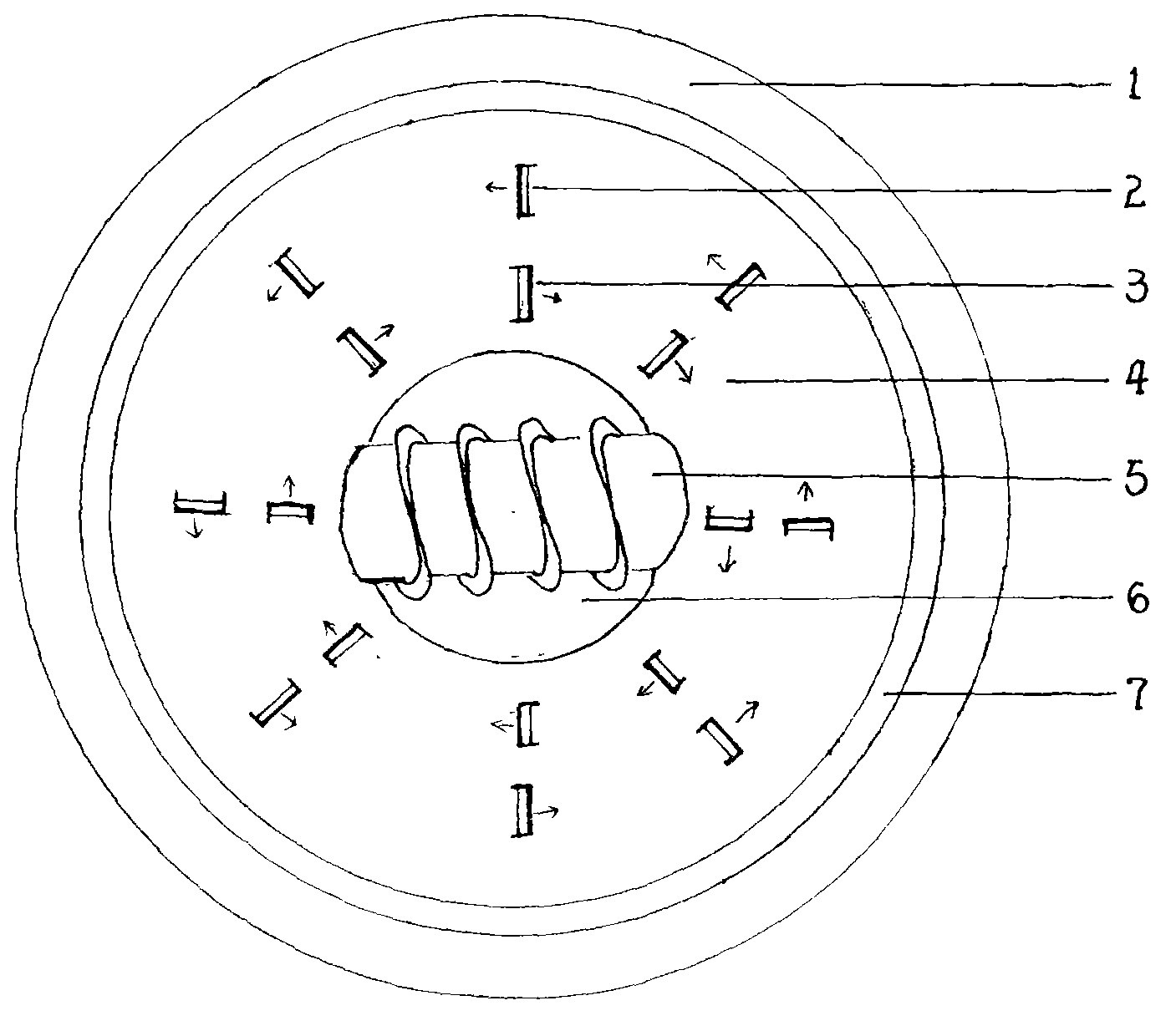

[0007] Example 1: A positive and negative air distribution structure of a biomass burner, including a panel (1), a secondary positive air distribution hole (2), a secondary reverse air distribution hole (3), a combustion chamber (4), and a feed Shaft (5), primary air distribution (6), bellows (7), feed shaft (5) is provided in the middle of the combustion chamber (4), and upper and lower distribution The air holes are respectively the secondary positive distribution air hole (2) layer and the secondary reverse distribution air hole (3) layer. The branch of the secondary positive distribution air hole (2) forms an off-angle with the cut surface of the combustion chamber (4), The deflection angles of the branches of the air distribution holes on the same floor are the same, the deflection angles of the branches of the secondary reverse air distribution holes (3) are opposite to those of the secondary positive air distribution holes (2), and the deflections of the branches of the ...

Embodiment 2

[0008] Example 2: A positive and negative air distribution structure of a biomass burner, including a panel (1), a secondary positive air distribution hole (2), a secondary reverse air distribution hole (3), a combustion chamber (4), and a feed Shaft (5), primary air distribution (6), bellows (7), feed shaft (5) is provided in the middle of the combustion chamber (4), and upper and lower distribution The air holes are respectively the secondary positive distribution air hole (2) layer and the secondary reverse distribution air hole (3) layer. The branch of the secondary positive distribution air hole (2) forms an off-angle with the cut surface of the combustion chamber (4), The deflection angles of the branches of the air distribution holes on the same floor are the same, the deflection angles of the branches of the secondary reverse air distribution holes (3) are opposite to those of the secondary positive air distribution holes (2), and the deflections of the branches of the ...

Embodiment 3

[0009] Example 3: A positive and negative air distribution structure of a biomass burner, including a panel (1), a secondary positive air distribution hole (2), a secondary reverse air distribution hole (3), a combustion chamber (4), and a feed Shaft (5), primary air distribution (6), bellows (7), feed shaft (5) is provided in the middle of the combustion chamber (4), and upper and lower distribution The air holes are respectively the secondary positive distribution air hole (2) layer and the secondary reverse distribution air hole (3) layer. The branch of the secondary positive distribution air hole (2) forms an off-angle with the cut surface of the combustion chamber (4), The deflection angles of the branches of the air distribution holes on the same floor are the same, the deflection angles of the branches of the secondary reverse air distribution holes (3) are opposite to those of the secondary positive air distribution holes (2), and the deflections of the branches of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com