Process method for cancelling central coke charging

A process method, coke technology, applied in the direction of bell and funnel arrangement, furnace, blast furnace details, etc., can solve the problems of poor gas utilization rate and high fuel ratio, and achieve the improvement of gas utilization rate, uniform feeding, and prolongation of the forward cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with example, the present invention will be further described.

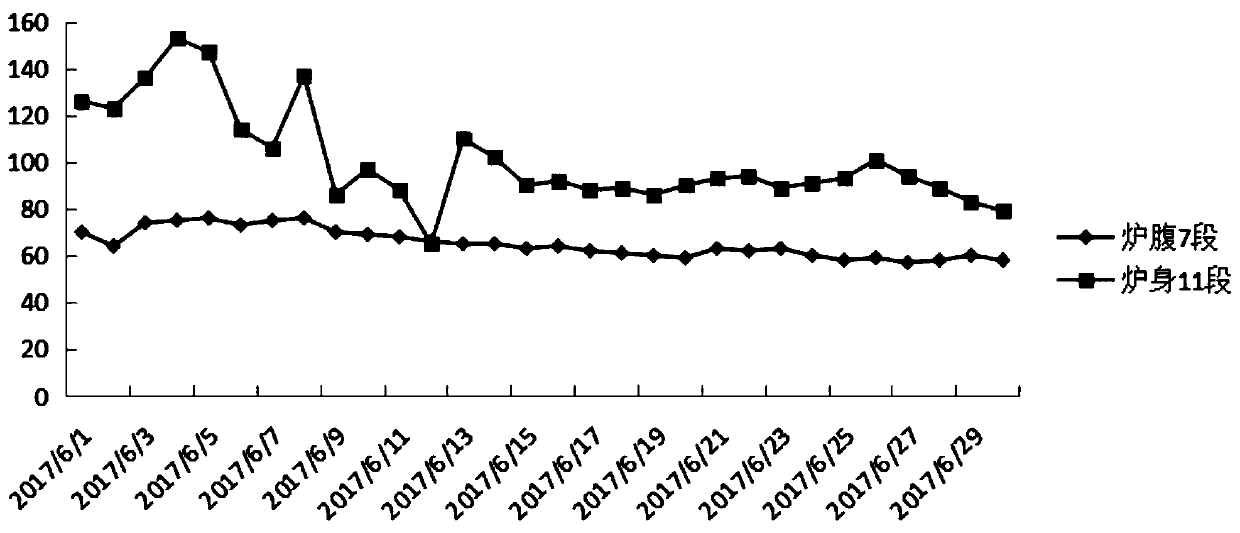

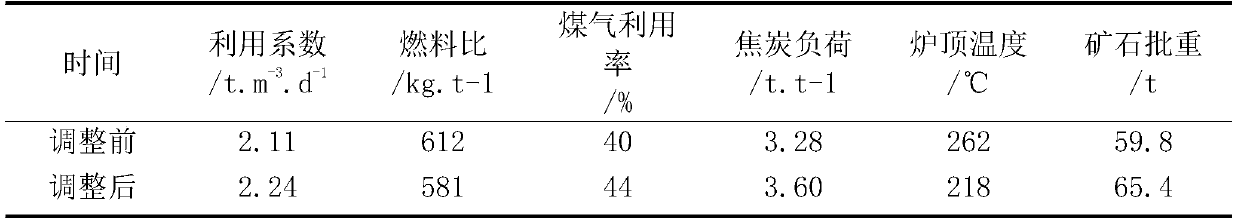

[0018] Since a blast furnace in Baotou Steel was put into production, it has long used the central coke distribution mode. Although the stability is good, the gas utilization is poor and the fuel consumption is high. A reasonable operation policy and adjustment plan have been established, especially the in-depth research on the fabric pattern, and the fabric pattern has successfully transitioned from the center-focused type to the "platform + funnel" type.

[0019] The first stage: On the premise of stabilizing the central airflow, reduce the ore platform and loosen the edge airflow. Starting from June 7, 2017, the end angle of coke distribution changed from 23° to 33°, the batch weight of ore increased from 59.8t to 60.6t, and the batch weight of ore gradually increased to 62.6t in the next two days, and the distribution matrix changed from tweak to Reduce 1 level of ore, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com