Injector gas fume preheating efficient combustor

An injection-suction and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as difficult control, low thermal efficiency, and inability to reuse flue gas well, and achieve reasonable air distribution and thermal efficiency. The effect of high and good thermal vibration conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

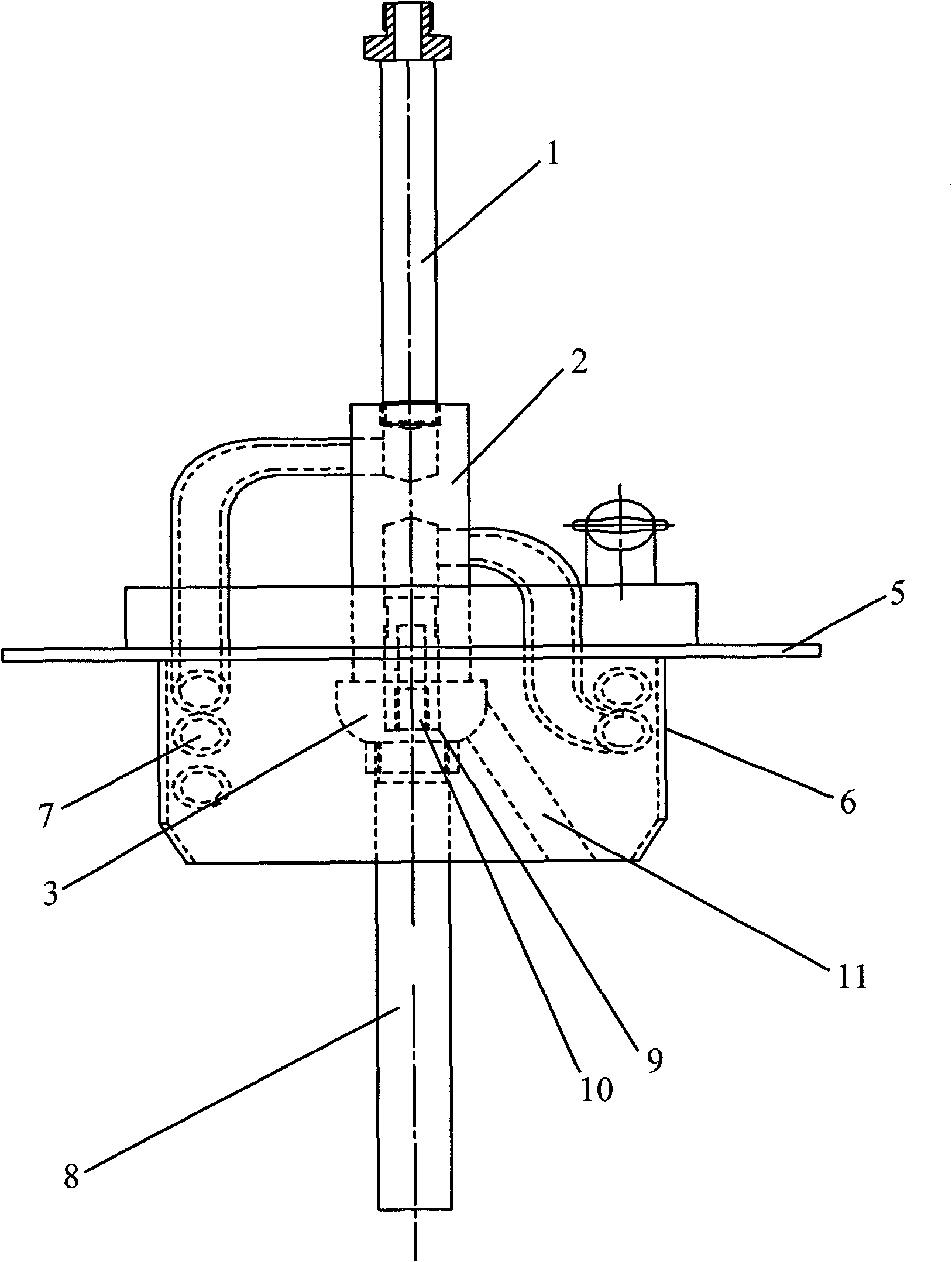

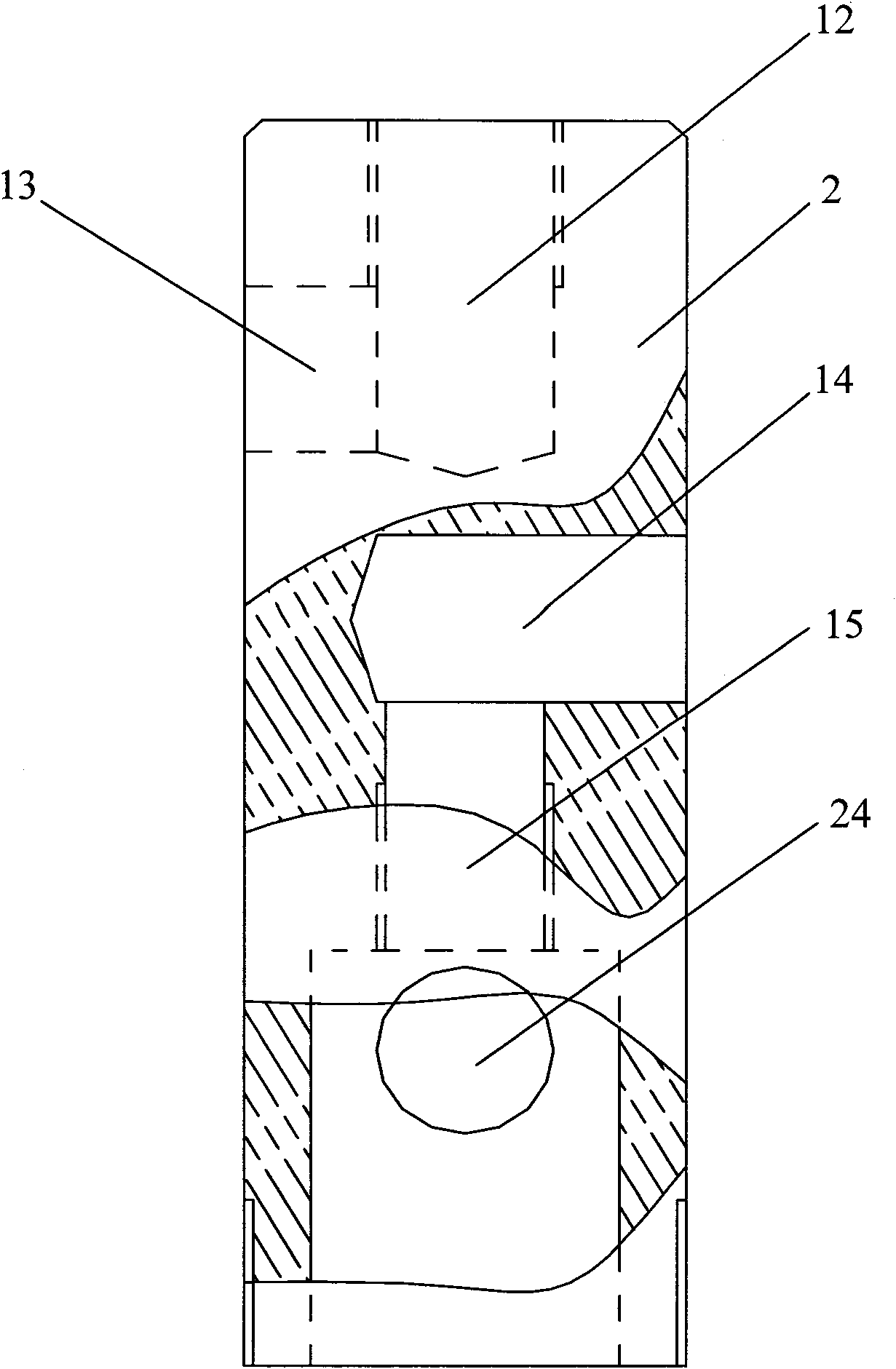

[0030] Such as figure 1 As shown, the upper plate 5 and the air preheating channel of the present invention are both a cylinder, and the diameters of the upper plate 5 and the air preheating channel are much larger than their respective heights, so that the upper plate 5 and the air preheating channel are in the same shape All are disc-shaped. At the same time, the air preheating channel is fixed on the upper end surface of the upper plate 5, and a bottom barrel 6 is arranged on the lower end surface of the upper plate 5, and the bottom barrel 6 and the air preheating channel are fixed with the upper plate 5 as In one piece, during installation, the bottom bucket 6 needs to be placed inside the fire well mouth of the fire channel.

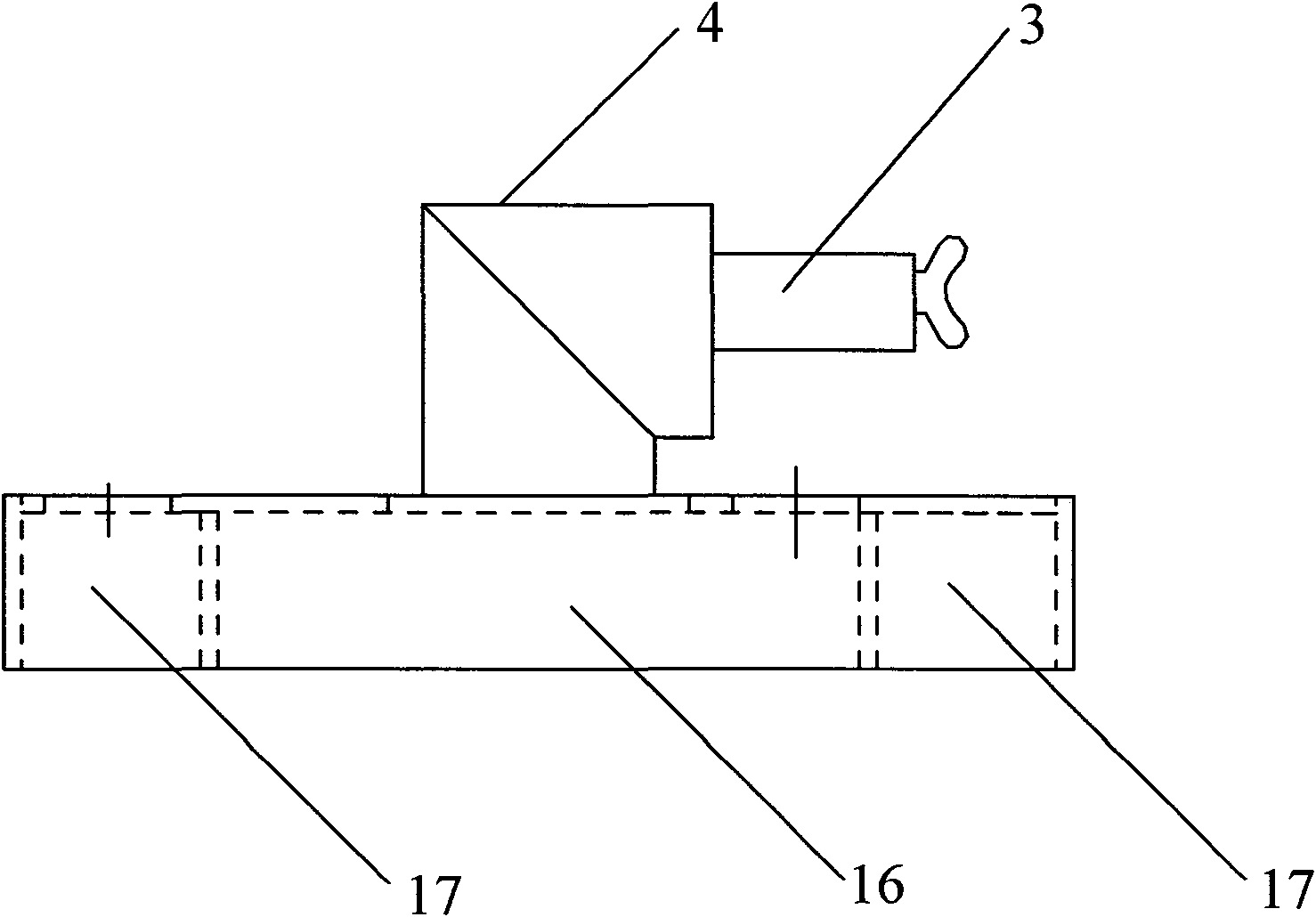

[0031] The structure of the air preheating channel is as follows image 3 , 4 As shown, there is an upper large through hole 16 and two upper small through holes 17 on the cylinder of the air preheating passage. The upper large through hole 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com