Air-base direct reduction iron-making method for reducing iron concentrate powder by self-reforming of gas rich in methane

An iron concentrate and methane-enriched technology, which is applied in the direction of reducing gas emissions, can solve the problems of high production cost, low efficiency, and inability to directly use concentrate powder, etc., and achieves high production efficiency, high gas utilization rate, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

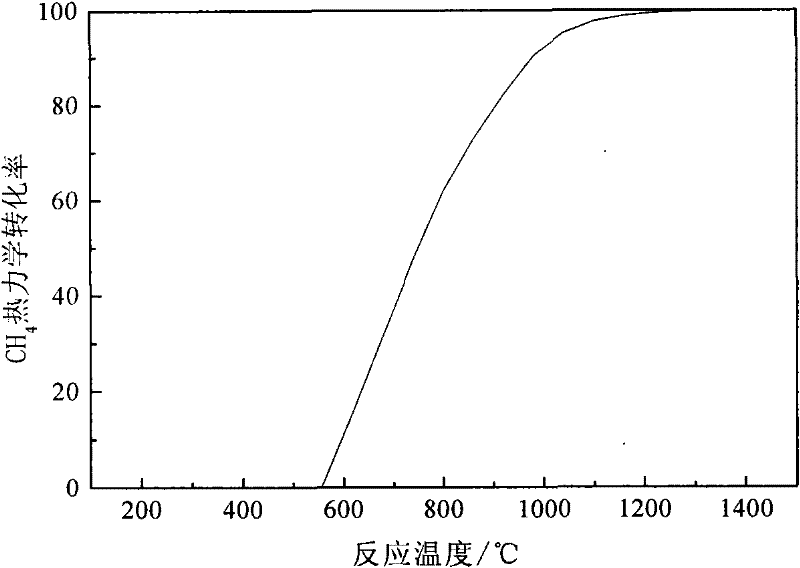

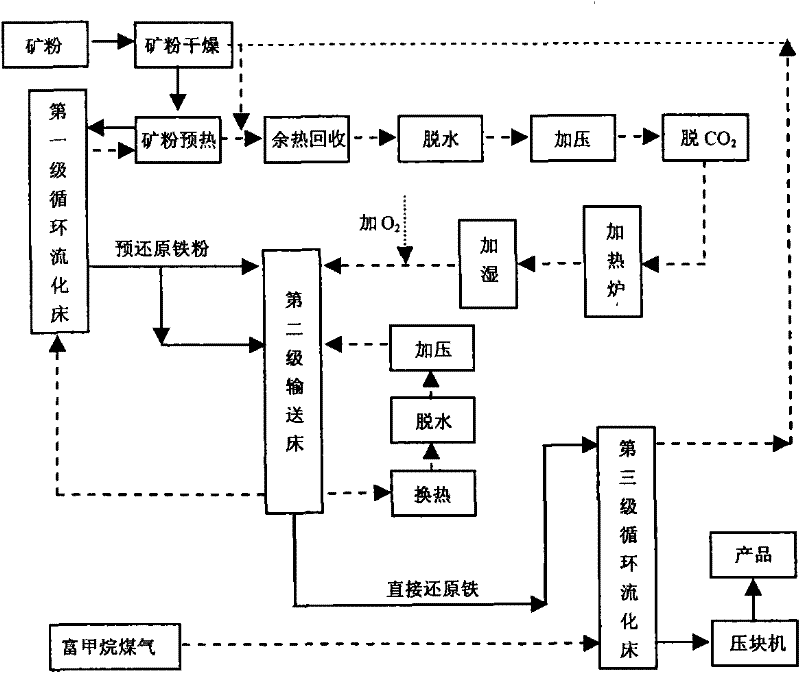

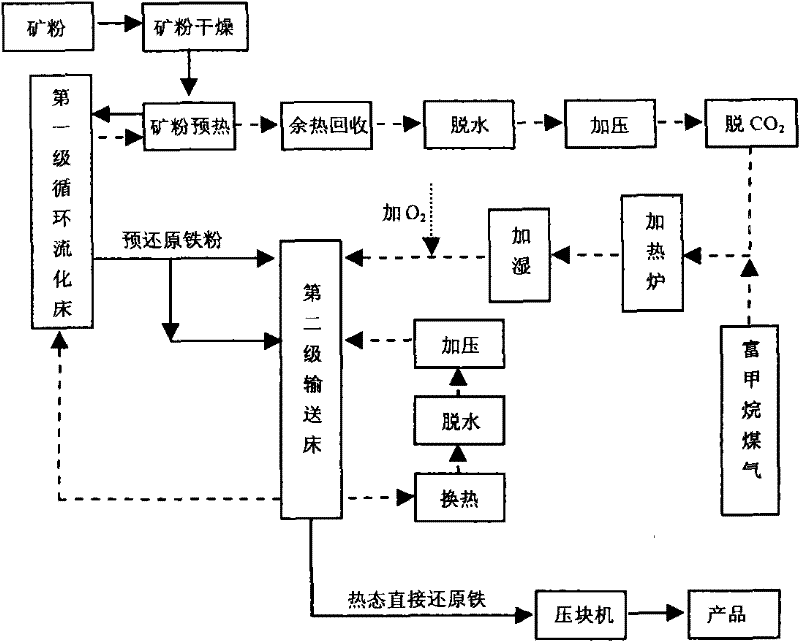

[0040] In this example, magnetite concentrate powder and hematite powder are used as raw materials. After the hematite is crushed, ground and sieved, the particle size of the two kinds of ore powder is 0.2-0.4mm. The magnetite composition is: TFe 66.1% , SiO 2 4.0%, Al 2 o 3 0.6%, CaO 2.0%, MgO 1.9%; hematite composition: TFe 64.2%, SiO 2 5.1%, Al 2 o 3 2.8%, CaO 0.6%, MgO 0.5%. The reduction gas uses coke oven gas and methane gas as the gas source respectively, and the coke oven gas composition is: CH 4 24.5%, CO 2 2%, CO 6%, N 2 6.5%, H 2 O 2.8%, C n h m 2.0%, BTX 5g / Nm 3 , H 2 56%. The process equipment includes circulating fluidized bed device, high temperature conveying bed device, heat exchange, dehydration and dust removal device, gas heating device, humidification device, carbon dioxide pressure swing adsorption device, gas pressurizer, oxygen blowing system, automatic control system and briquetting device etc. During the experiment, the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com