Pressure swing adsorption gas separation energy-saving technique

A technology of pressure swing adsorption and gas separation, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high energy consumption for drying, high energy consumption cost of PSA process, large amount of regeneration gas, etc. The effect of reasonable process energy saving, energy consumption reduction, and energy consumption cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

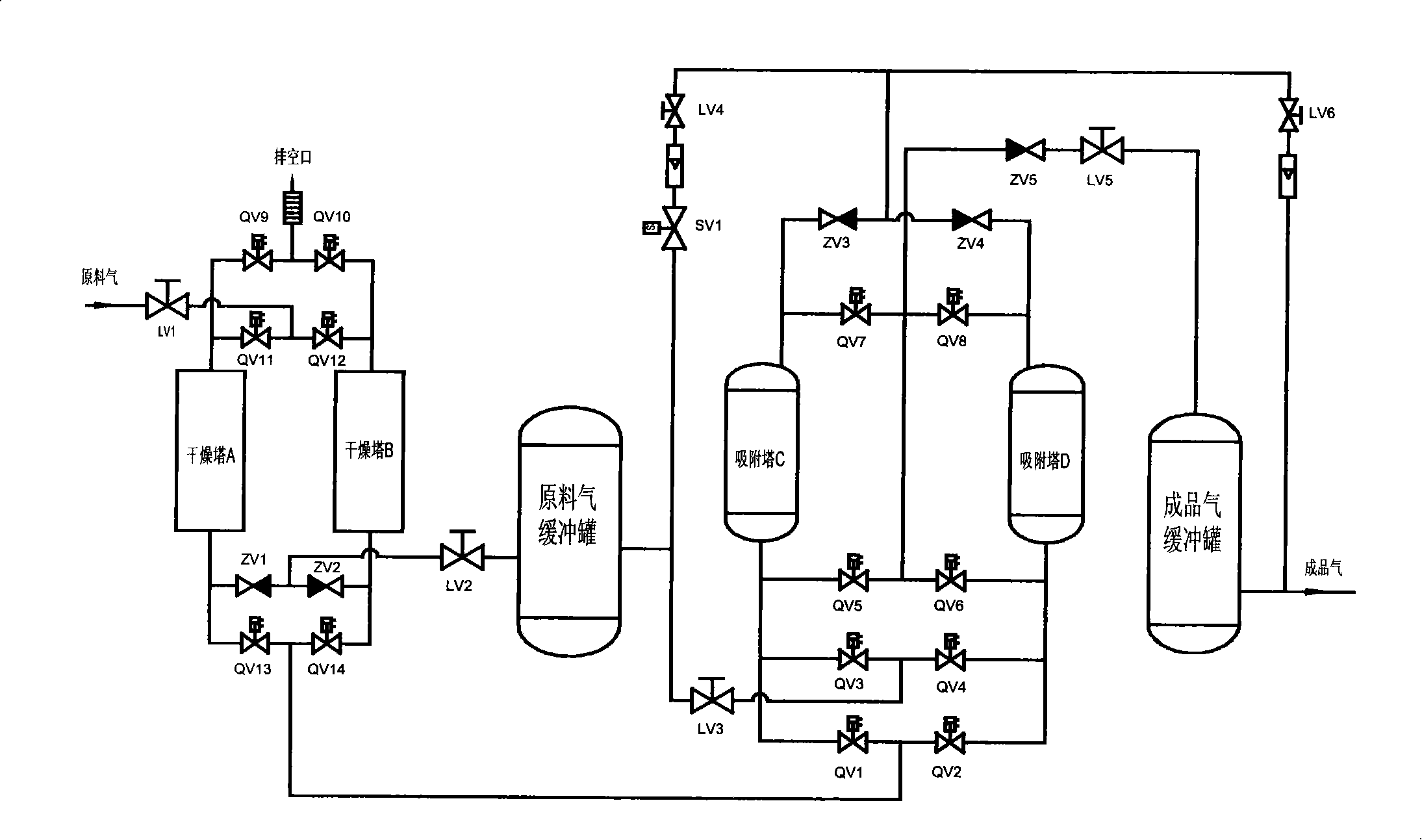

[0010] Example: As shown in the figure, in this example, a double-tower type heatless regeneration drying equipment is used to dry the raw material gas, and a double-tower type PSA equipment is used for gas separation. Of course, equipment with different number of towers can also be used as needed. .

[0011] When the drying tower A is in the regeneration state, the drying tower B is in the working state. The raw material gas is sent to the drying tower B through valves LV1 and QV12 for deep drying. After drying, the gas is sent to the raw material gas buffer tank through valves ZV2 and LV2 for storage. At this time, the adsorption tower C in the PSA equipment is in the regeneration state, and the adsorption tower D is in the working state. The dry raw gas enters the adsorption tower D through the valves LV3 and QV4. After the adsorption gas is separated, it is sent to the product gas buffer from the valves QV8, ZV5 and LV5. output after the tank.

[0012] The vented tail ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com