Gas-liquid-solid three-phase membrane microreactor with stacked structure

A gas-phase reaction, gas-liquid-solid technology, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of small reactant processing capacity, inability to scale up production, Increase the economic cost and other issues to achieve the effect of facilitating the enlargement of the design, improving the gas utilization rate and increasing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples. However, it should be noted that implementation of the present invention is not limited to the following embodiments.

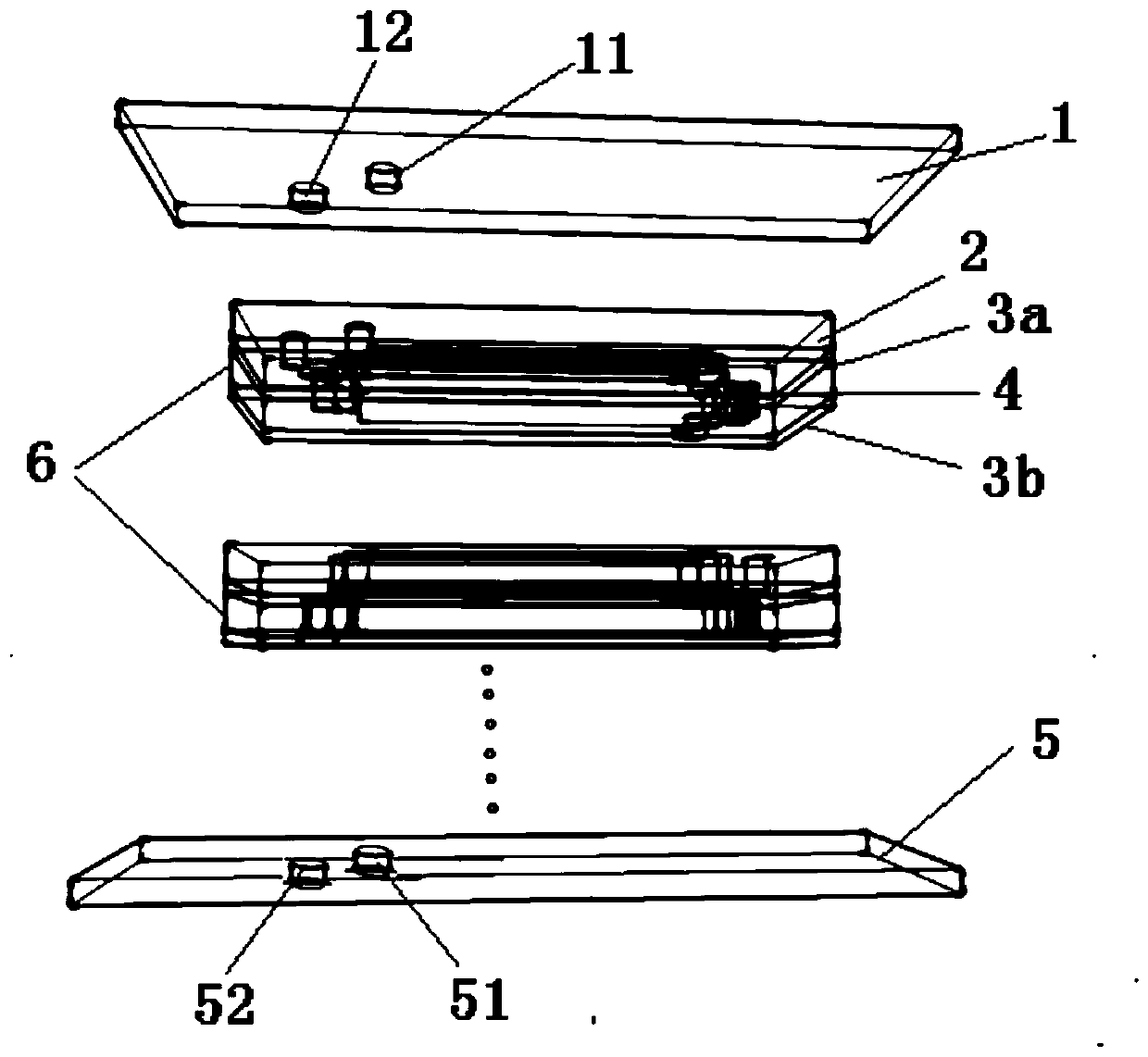

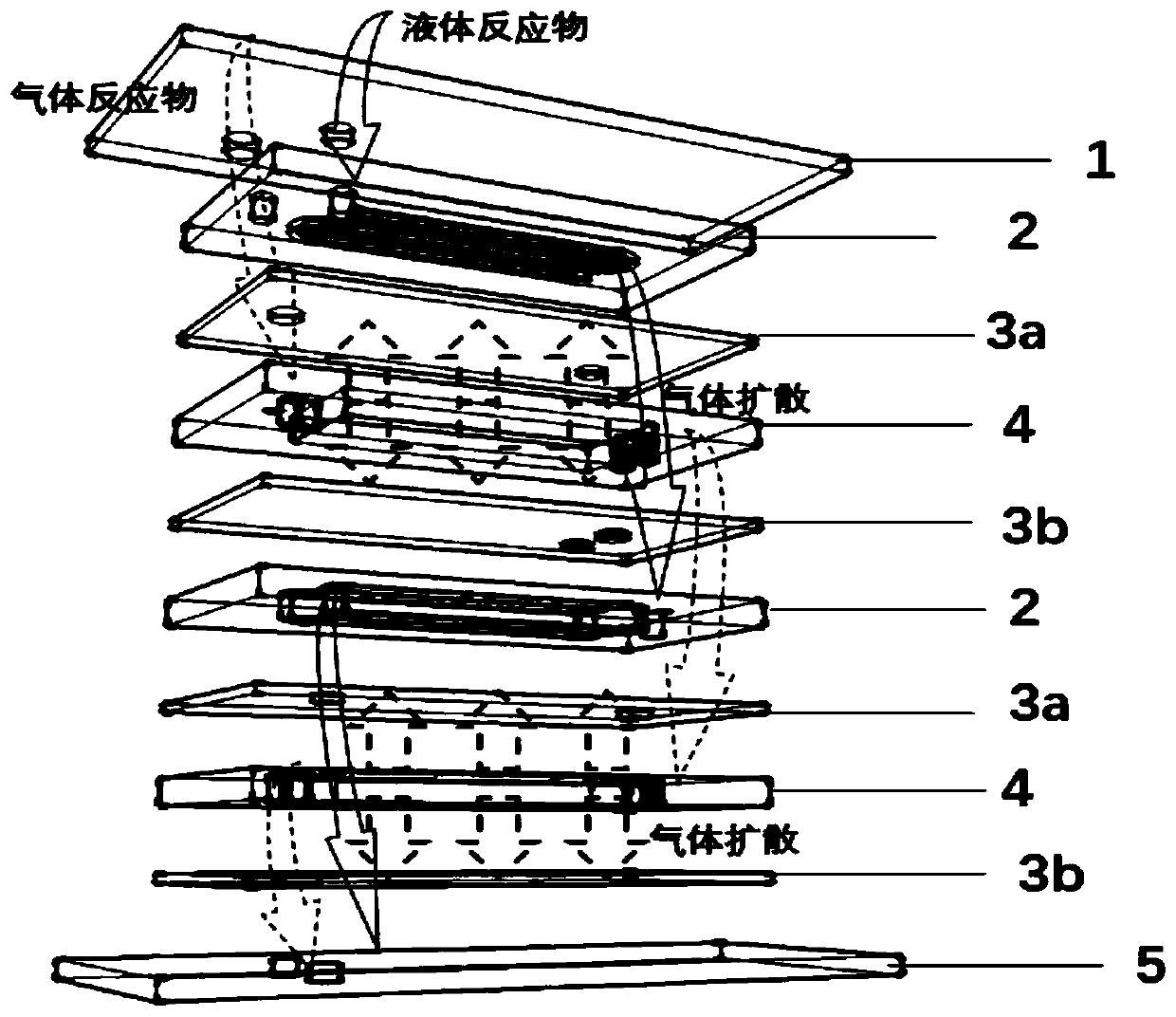

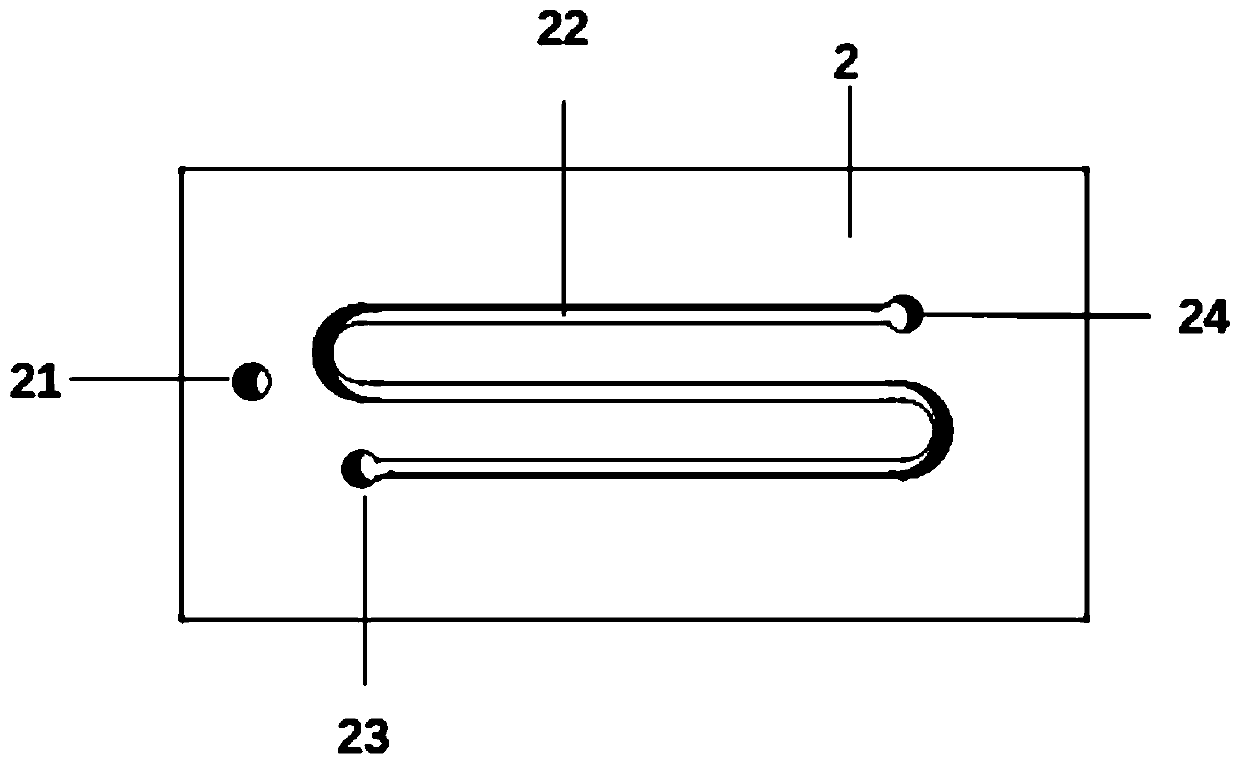

[0022] see Figure 1 to Figure 6 , a gas-liquid-solid three-phase membrane microreactor with a stacked structure, comprising an upper cover plate 1 and a lower cover plate 5; the upper cover plate 1 is provided with a liquid phase inlet 11 and a gas phase inlet 12; the lower cover plate 5 is provided with There are a liquid phase outlet 51 and a gas phase outlet 52; between the upper cover plate 1 and the lower cover plate 5, several three-phase micro-reaction units 6 are stacked up and down; each three-phase micro-reaction unit 6 is composed of a liquid phase micro-channel Layer 2, the first gas-permeable membrane 3a, the gas-phase microchamber layer 4 and the second gas-permeab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com