Ammonia synthesis waste gas recycling device

A waste gas recovery and ammonia synthesis technology, which is applied in steam condensation, ammonia preparation/separation, inert gas compounds, etc., can solve the problems of inability to extract argon, low recycling rate, and complicated equipment, so as to improve gas utilization rate and reduce waste , the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred implementation of the ammonia synthesis waste gas recovery and utilization device of the present invention will be described in detail below in conjunction with the accompanying drawings.

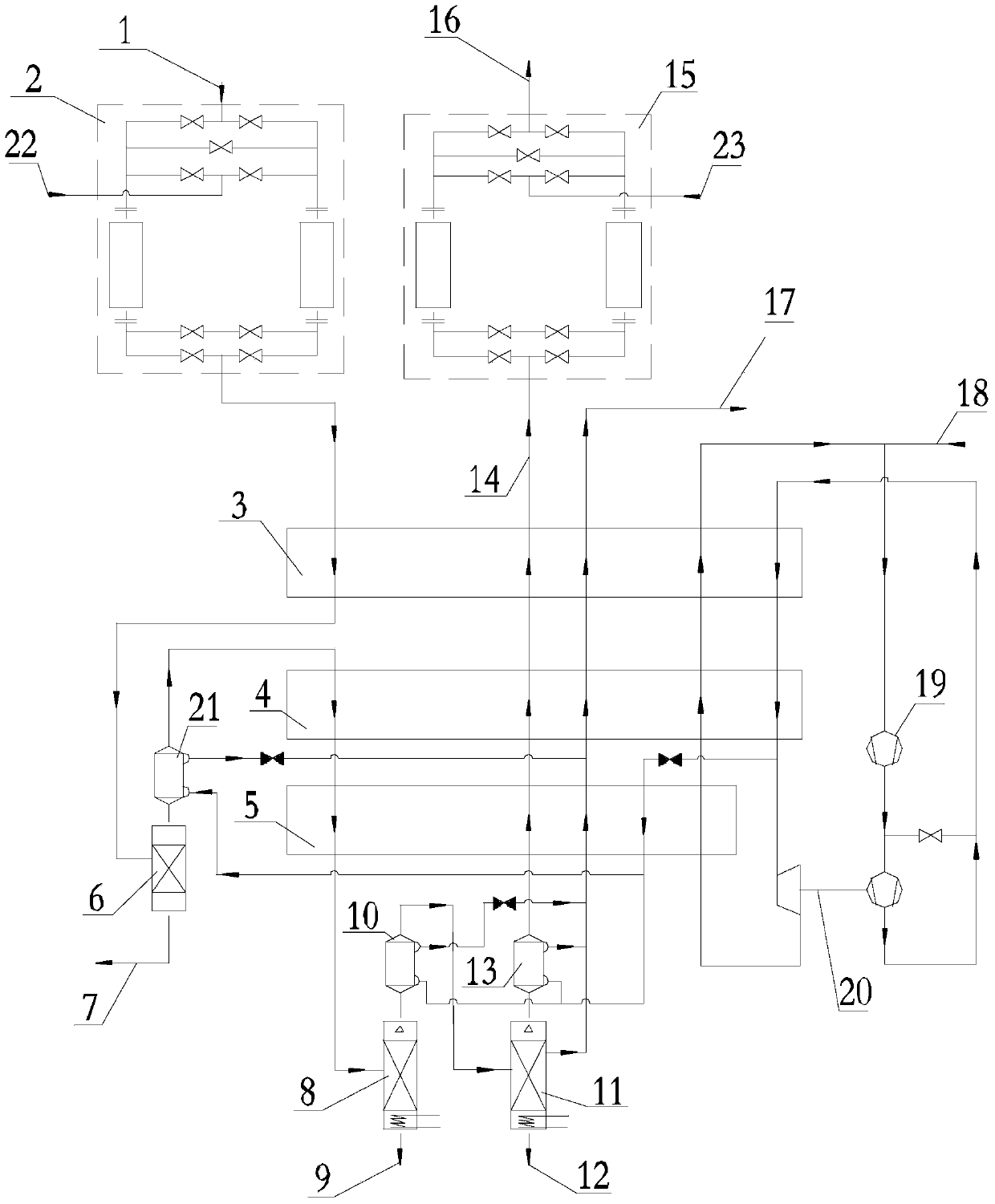

[0010] attached figure 1 The schematic diagram of the structure of the ammonia synthesis waste gas recovery and utilization device of the present invention is shown. Synthetic ammonia waste gas enters the device from the air inlet 1, and passes through the decarburization adsorber 2, the first heat exchanger 3, the liquid ammonia rectification tower 6, the liquid ammonia rectification tower condenser 21, the second heat exchanger 4, and the third Heat exchanger 5, methane rectification tower 8, methane rectification tower condenser 10, argon rectification tower 11, argon rectification tower condenser 13, the remaining gas is a mixture of hydrogen and other gases, wherein hydrogen Lead to the hydrogen pipeline 14 for purification, and the remaining non-toxic and harmles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com