Four-speed power air and gas synchronous control valve

A synchronous control and air technology, applied in multi-port valves, valve devices, engine components, etc., can solve the problems of large randomness, heat loss, low energy utilization rate, etc., and achieve reasonable gas-to-air ratio and full and complete gas combustion. , the effect of improving the utilization rate of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

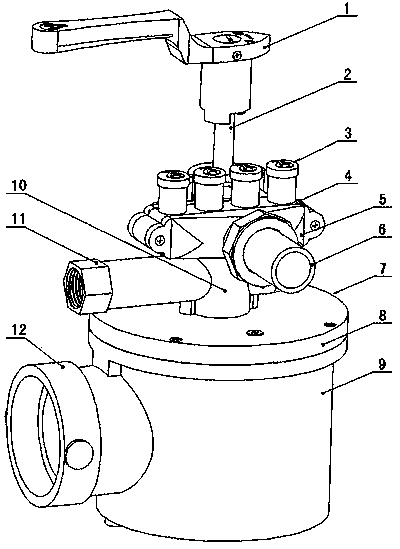

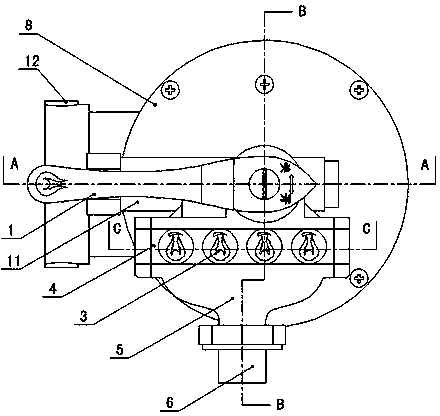

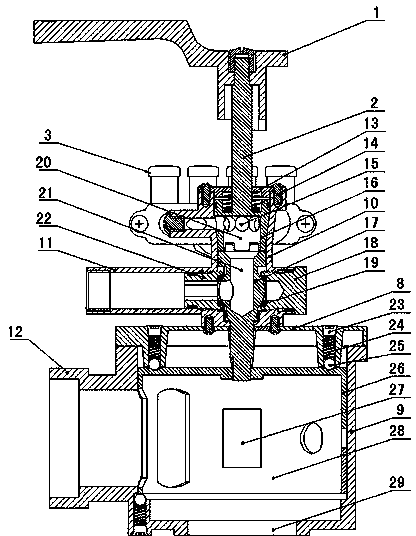

[0020] Figure 1 to Figure 5 Shown is a specific implementation of a four-stage power air synchronous control valve created by the present invention. It includes a handle 1, a valve stem 2, a gas valve, and an air valve 7. The air valve 7 is fixed on the gas valve. The valve includes a valve cover 13, an inlet valve core 16, an outlet valve core 17, and a valve body 10. The valve stem 2 is fixed to the inlet valve core 16, and the inlet valve core 16 and the outlet valve core 17 are arranged on the valve in a sealing manner. On the body 10, the intake valve core 16 is provided with an intake chamber 20, and the outlet valve core 17 is provided with an outlet chamber 21 communicating with the intake chamber 20, and the outlet chamber 21 corresponds to the outlet connector 11 on the valve body 10; The air valve 7 includes an air valve cover 8, an air valve core 26, and an air valve body 9. The air valve cover 8 is fixed on the air valve body 9, and the air valve core 26 is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com