Agricultural equipment harvester gearbox assembly line

A technology for assembling production lines and gearboxes, which is applied to conveyors, transportation, and packaging. It can solve problems such as unclear box fixing, difficult assembly, and waste of manpower, and achieve the effects of high degree of automation, convenient operation, and reasonable equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

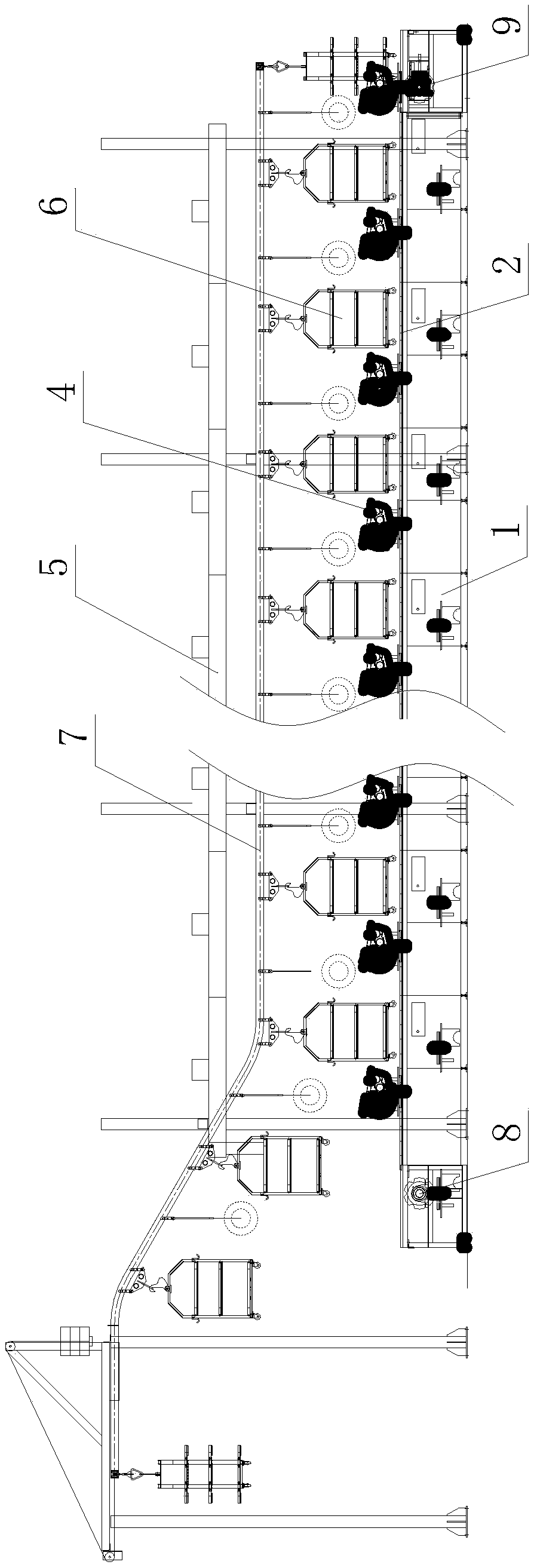

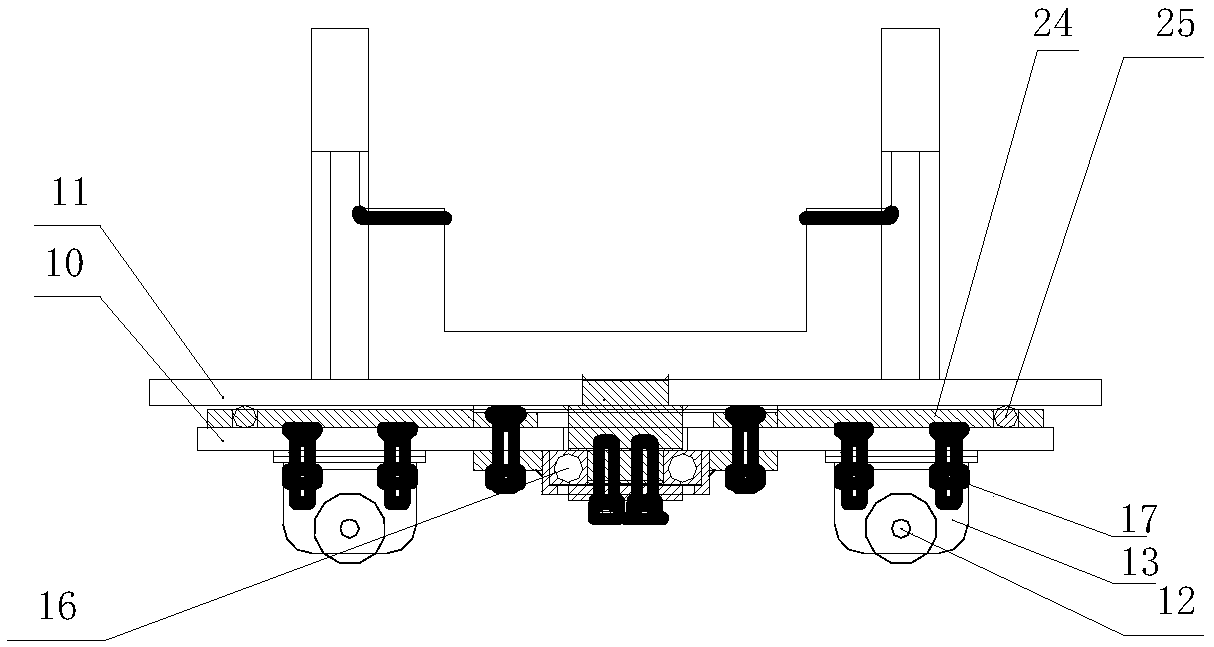

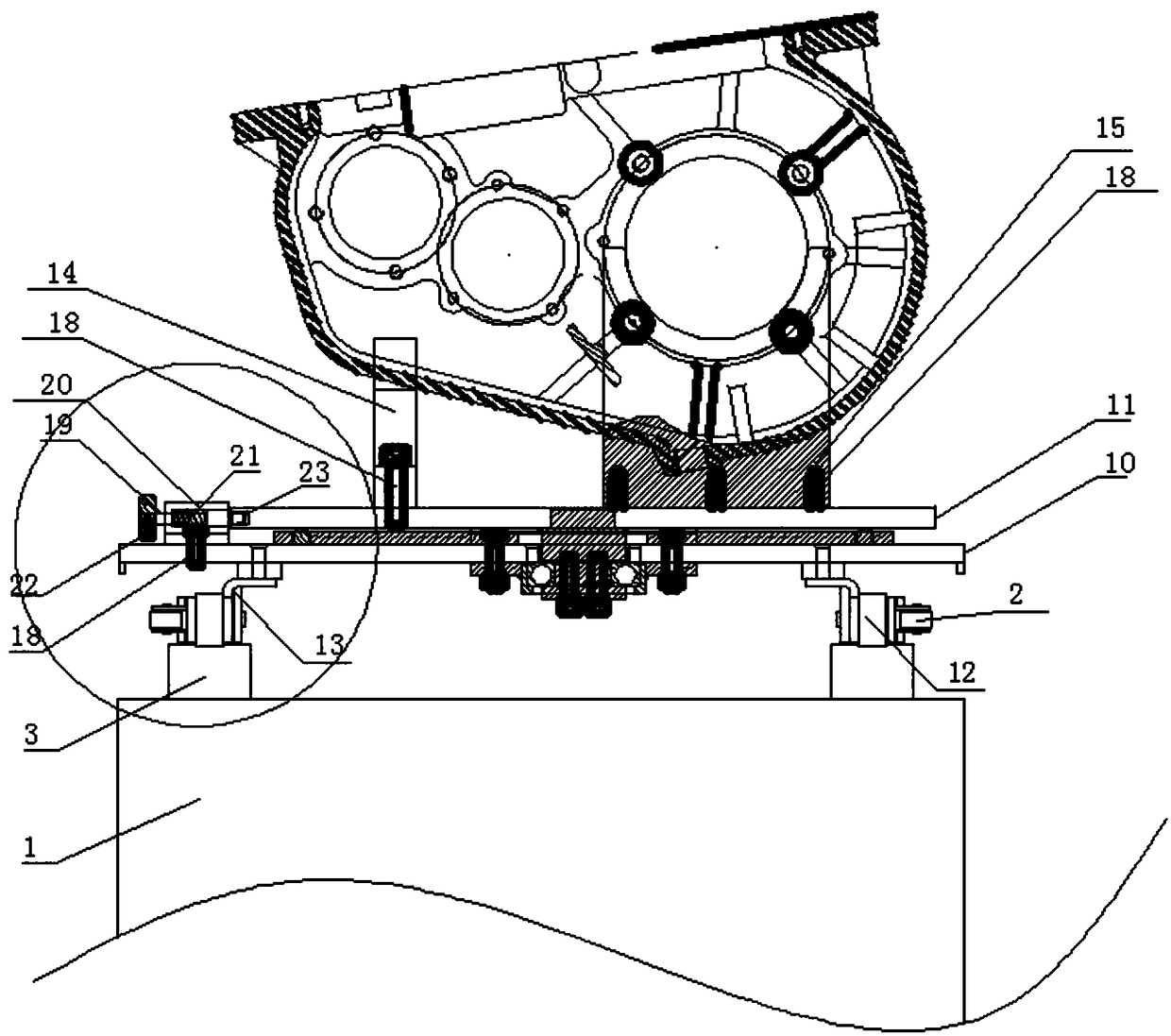

[0020] like figure 1 As shown, the agricultural equipment harvester gearbox assembly production line involved in this embodiment includes an assembly line body 1, an assembly line chain 2, an assembly line guide rail 3, a fixed rotary table 4, a material line body 5, a material distribution vehicle 6, and a material chain 7. The assembly line drive motor 8 (9) and the material line drive motor (not shown in the figure), several assembly line guide rails 3 are arranged on the assembly line body 1 in parallel along the length direction of the assembly line body 1, and the fixed rotary table 4 is placed on the assembly line guide rail 3 at intervals Above, the fixed rotary table 4 is connected to the assembly line chain 2 connected to the assembly line drive motor 8, and the assembly line drive motor 8 drives the assembly line chain 2 to move and then drives the fixed rotary table 4 to move along the assembly line guide rail 3, and the material line body 5 passes through several s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com