Engineering vehicle

A technology for engineering vehicles and frames, which is applied to vehicle components, control devices, transportation and packaging, etc., to achieve the effects of overall weight reduction, high transmission efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

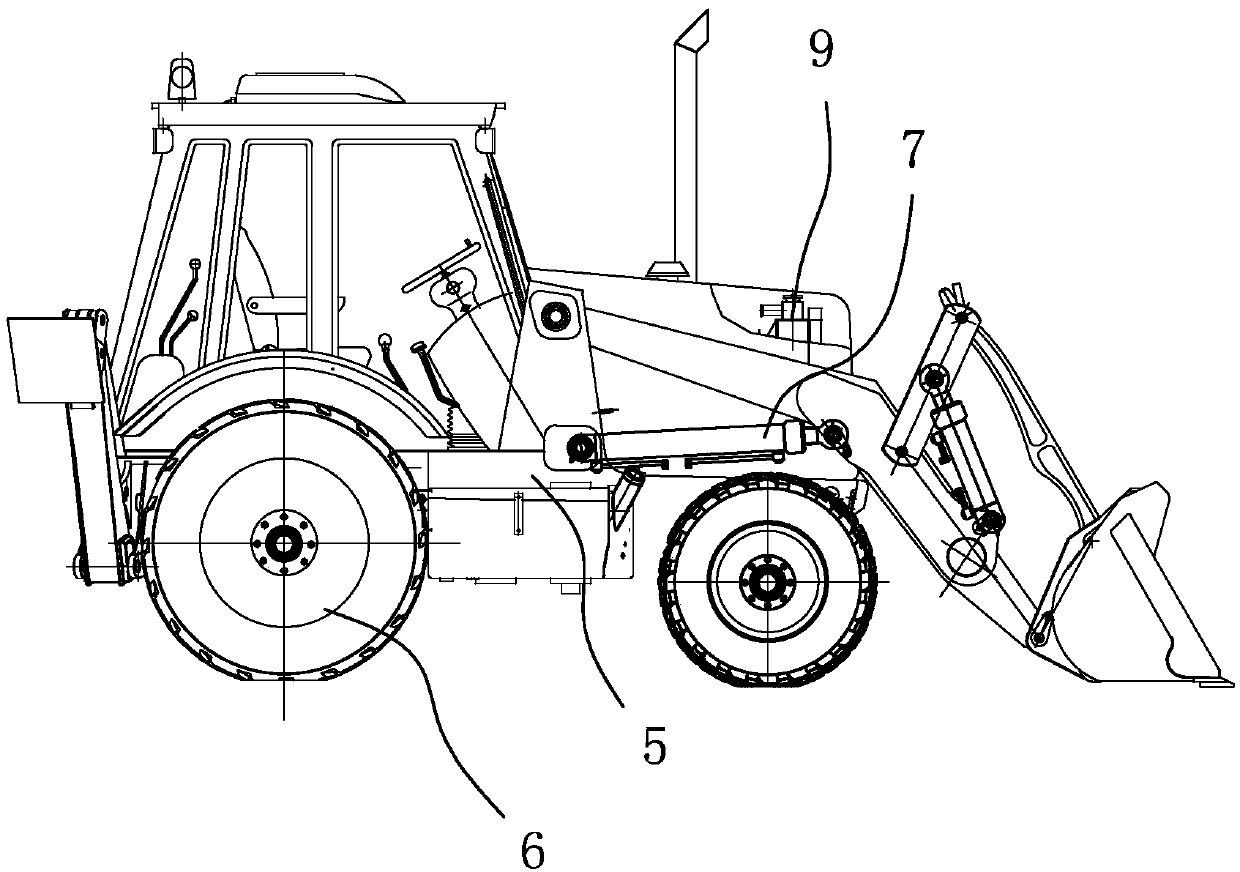

[0053] combine figure 1 and figure 2 As shown, this embodiment provides an engineering vehicle, more specifically, a loader. It includes a vehicle frame 5, on which a traveling device 6 and a power unit assembly 9 are arranged; on the vehicle frame 5, a hydraulic actuator 7 is also provided, and the hydraulic actuator 7 includes a hydraulic oil circuit, a hydraulic cylinder and Load the bucket assembly.

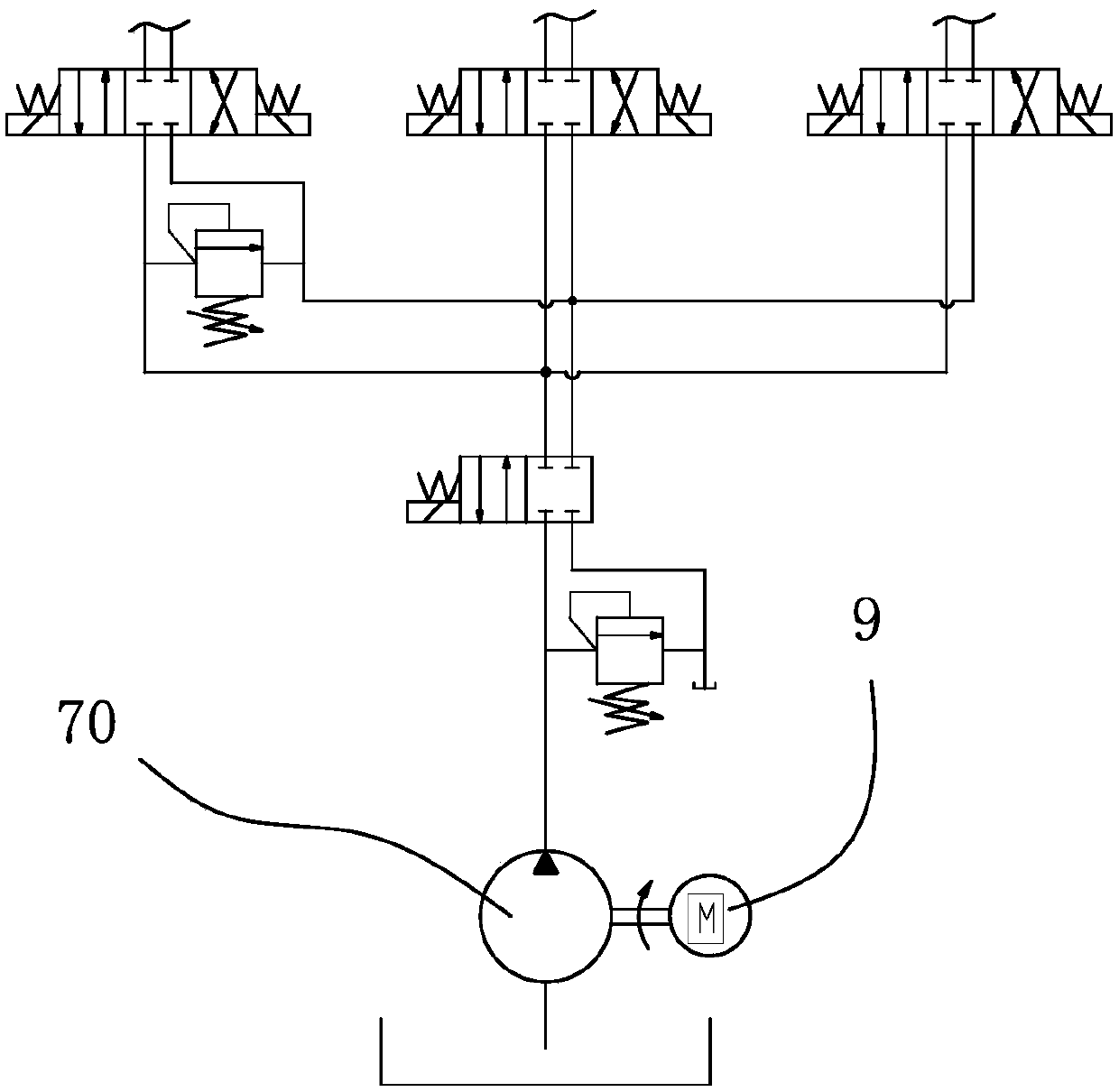

[0054] In this embodiment, the power device assembly 9 includes a gas power device: first, the gas power device is connected to the traveling device 6 through a clutch and a transmission; The hydraulic motor 70 transmission connection on the hydraulic oil circuit of the device; meanwhile, the vehicle frame 5 is also provided with a storage tank (not shown in the figure, preferably a steel cylinder, a Dewar tank, a high-pressure gas tank or gas storage bottle, which is arranged on the vehicle frame); the storage tank is connected to the gas power device through the valve b...

Embodiment 2

[0075] Example 2: See Figure 8 to Figure 11 , the engineering vehicle of this embodiment is basically the same as Embodiment 1, and its main difference is:

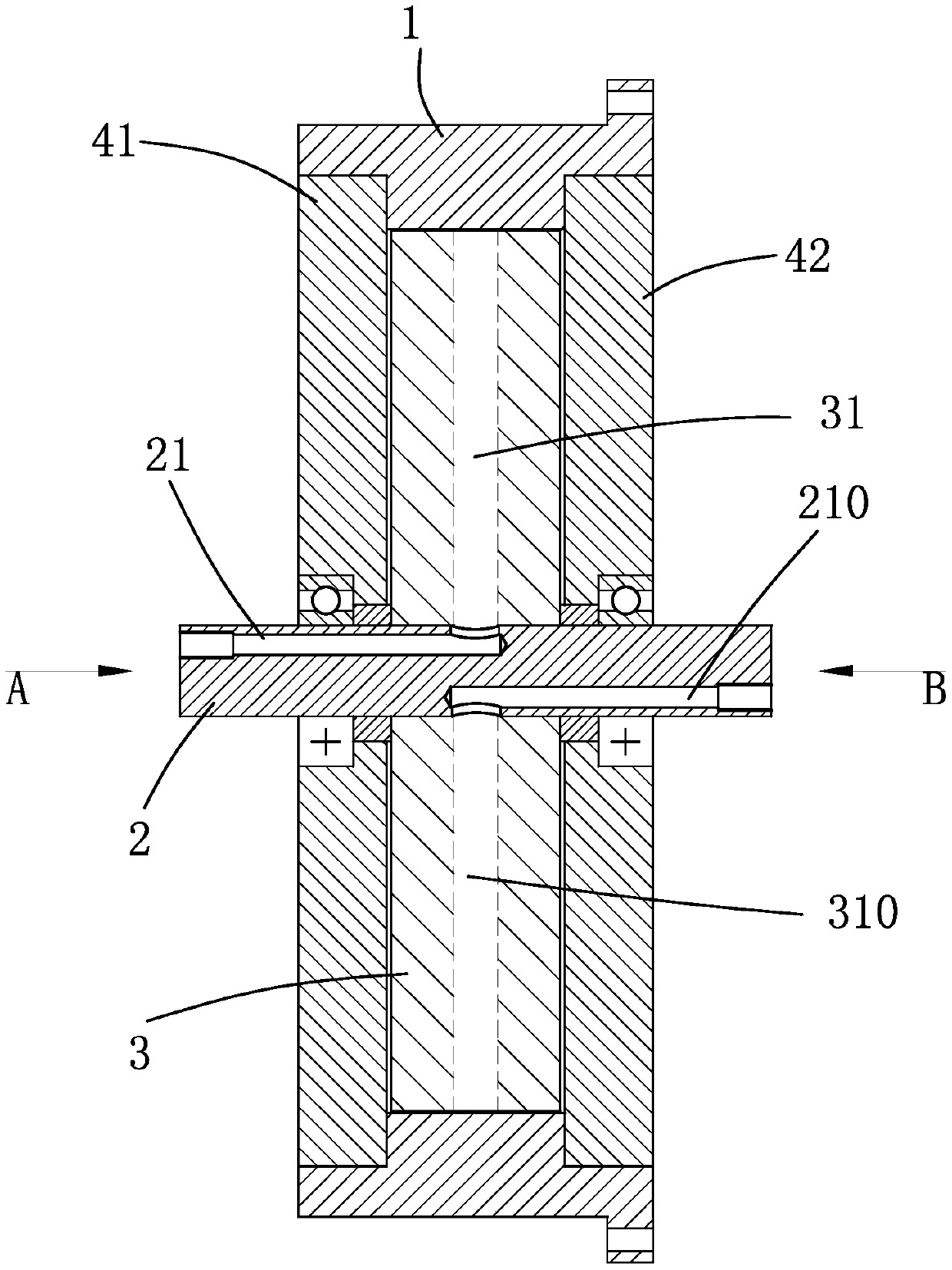

[0076] The gas power device includes 2 independent work units to form a secondary drive structure, that is, the core body 3 is provided with 2 air channels along the circumference, and each air channel includes an air intake channel 31 with a level above 1 and a secondary flushing channel 300 along the The core body 3 is arranged in the circumferential direction and the exhaust flow channel. The gas power device comprises an outer ring 1, a plurality of driving recesses 11 are arranged on the inner ring surface of the inner ring; 2 groups of nozzles, discharge ports, and at least one flushing channel between each group of nozzles and discharge ports; 2 air intake passages 31, 32 are provided on the core body, which correspond to the connecting nozzles; and 2 exhaust passages 310, 320 , which corresponds to the connecte...

Embodiment 3

[0078] Embodiment 3: The engineering vehicle of this embodiment is basically the same as Embodiment 1, and its main difference is:

[0079] The gas power device of the present invention includes 4 or more independent working units to form a multi-stage drive structure, and 3 or more air passages are arranged on the core body along the circumference, and each air passage includes an air intake passage of more than one order and The sub-impulse flow channel and the exhaust flow channel are arranged along the circumference of the core body, and the air intake channel and the exhaust channel are arranged on the mating surfaces of the left and right core bodies. The shaft is provided with the number of air inlet shafts and air outlet shafts corresponding to the number of air passages. Compressed gas enters from the shaft inlet shaft, and is ejected through the core body inlet flow channel to act on the driving recess of the outer ring, pushing the outer ring to rotate and do work. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com