Micro-bubble generation device based on plate type microporous medium foaming mechanism

A microporous medium and microbubble technology, which is applied in flotation water/sewage treatment and other directions, can solve the problems of fouling and blockage, low gas utilization rate, and high gas consumption, and achieves convenient disassembly and assembly, high gas utilization rate, and processing capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

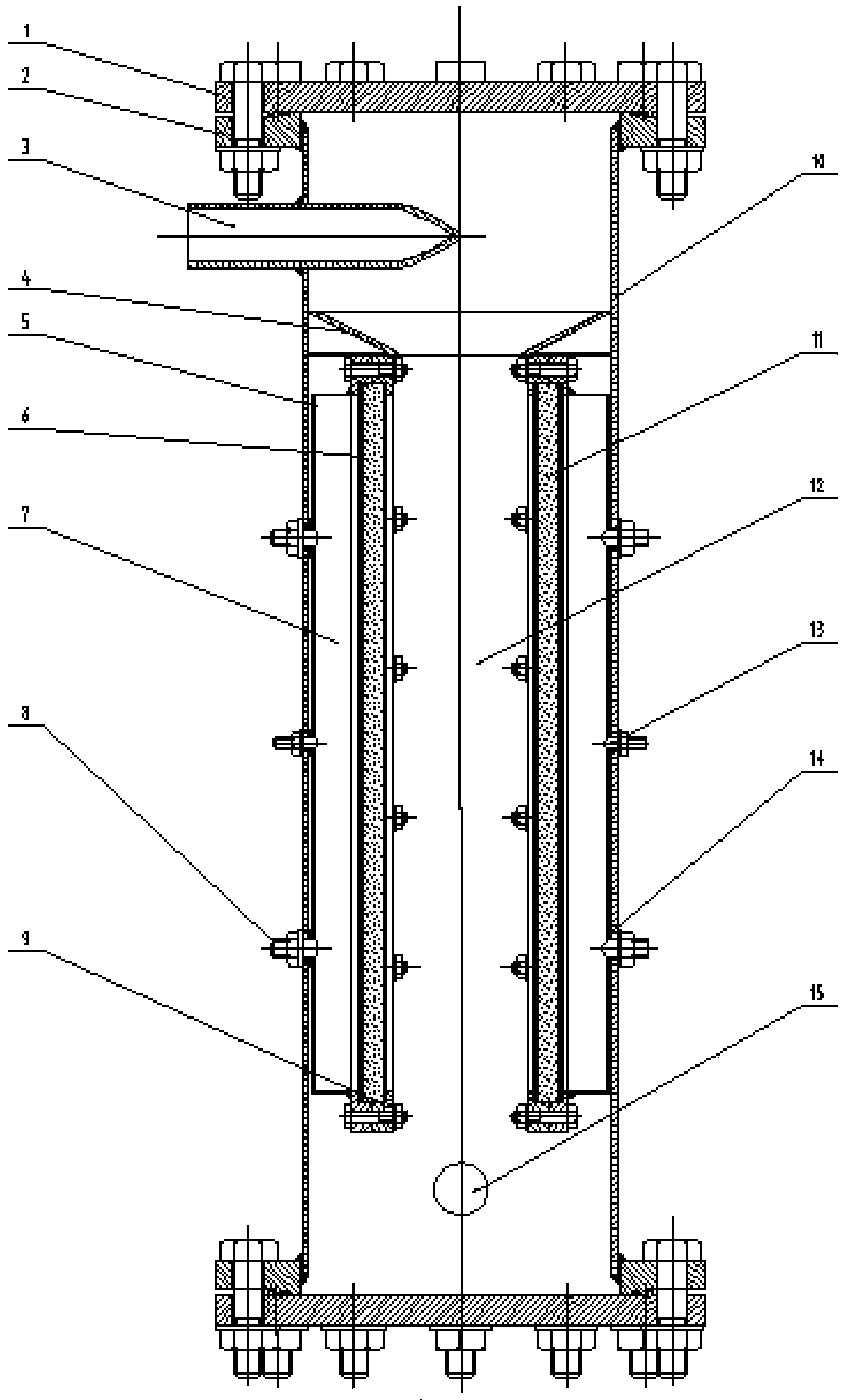

[0036] The preferred embodiment of the micro-bubble generating device based on the foaming mechanism of the plate-type microporous medium of the present invention is:

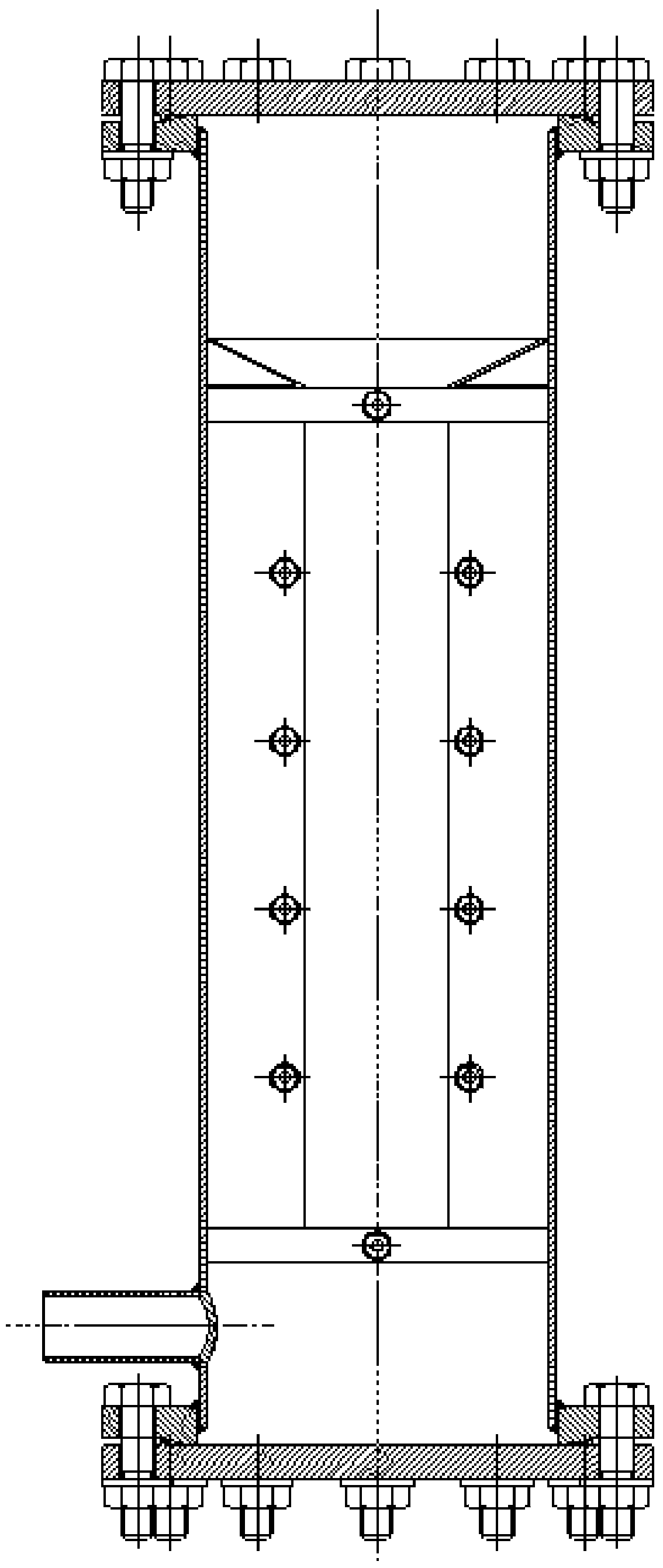

[0037] It includes a cylindrical outer cylinder, the upper end and lower end of the outer cylinder are respectively sealed by flange covers, and two independent gas chambers are separated from the parts of the outer cylinder near the two side walls. The other cavities in the cylinder are water flow chambers;

[0038] The upper part of the water flow chamber is provided with a conical guide cylinder, the upper space of the conical guide cylinder is a swirl cavity, and the wall of the outer cylinder at the swirl cavity is provided with a tangential water inlet pipe , a water outlet pipe is provided on the wall of the lower part of the outer cylinder;

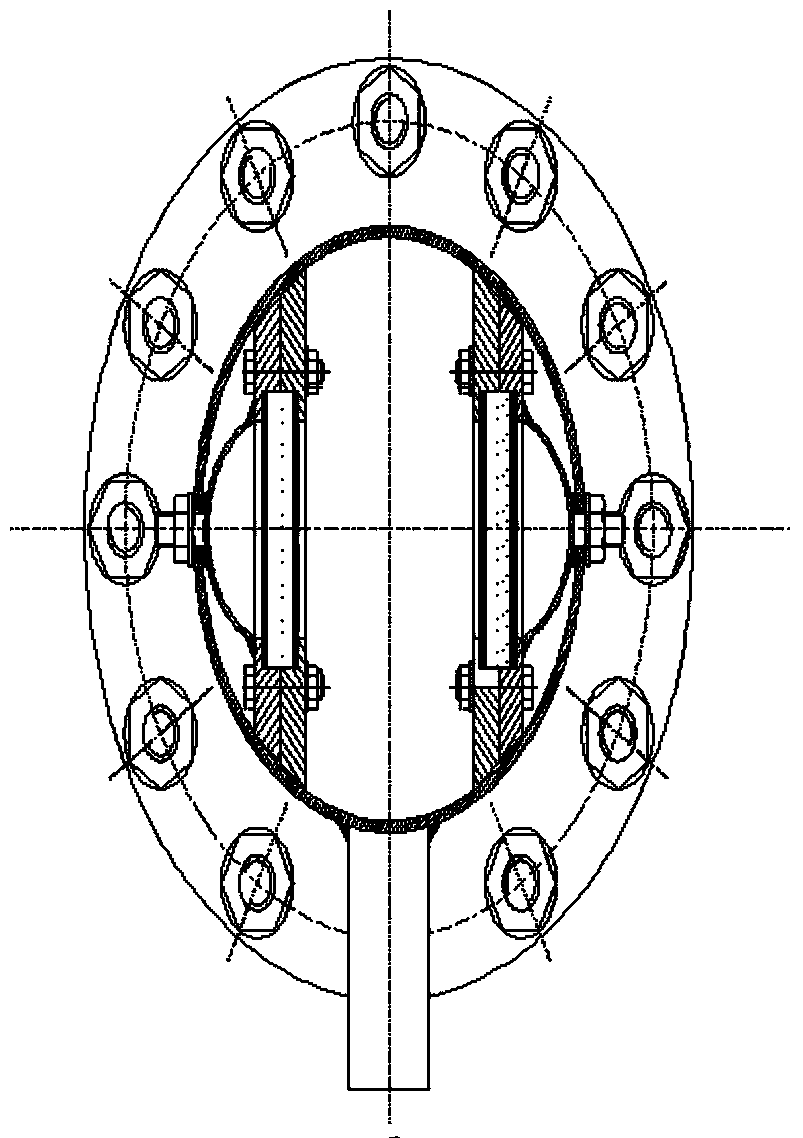

[0039] An inlet pipe is provided on the cylinder wall of the outer cylinder at the gas chamber, and a rectangular micro-orifice plate is provided between the gas ...

specific Embodiment

[0053] Such as Figure 1 to Figure 4 As shown, the entire internal space is composed of two major parts, the water flow chamber 12 and the gas chamber 7 . Among them, the water flow chamber 12 is mainly a closed space surrounded by the outer cylinder body 10 and the upper and lower flange covers 1, and is compressed and sealed by the action of bolts; the gas chamber 7 is composed of a tile-shaped upper end cover 5, a rectangular micro The independent space formed by the orifice plate 11 and the rectangular positioning frame 9. Wherein the rectangular microporous plate 11 can be made of ceramic material or metal material. The rectangular microporous plate 11 is placed in the groove between the rectangular positioning frame 9 and the tile-shaped upper end cover 5, and the rubber rectangular gasket 6 is placed up and down, and the bolts around the rectangular positioning frame 9 are tightened to achieve sealing. The gas chamber 7 is fixed by means of two threaded fixing rods 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com