Selective hydrogenation catalyst of alkine and diolefin, preparation method and application

A hydrogenation catalyst and selective hydrogenation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrocarbons, etc., can solve the problem of blocking pores, reducing reaction activity and selectivity, etc. problems, achieve the effect of reducing dosage, improving hydrogenation efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

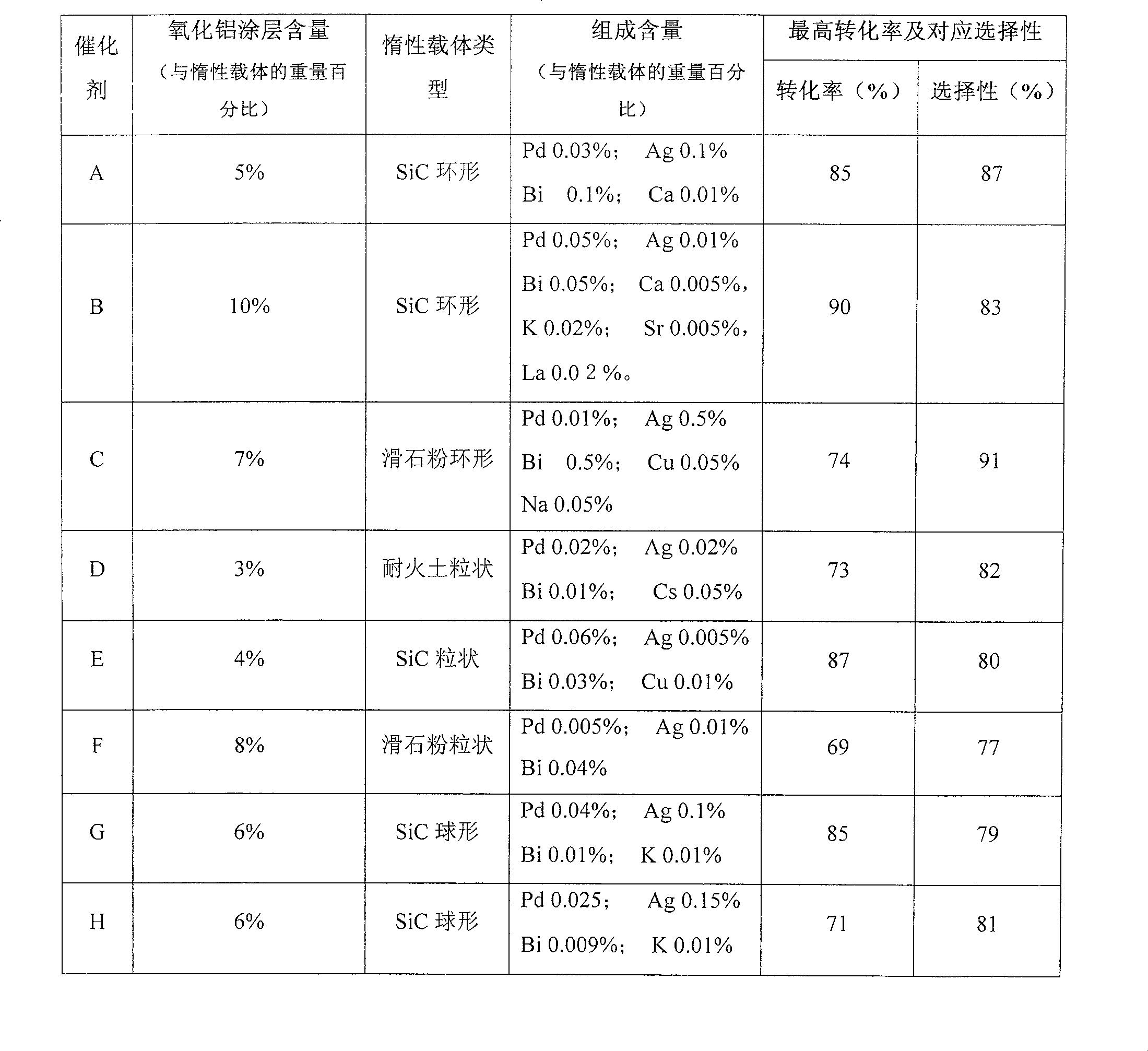

Examples

Embodiment 1

[0027] Will contain 5gAl 2 o 3 20% Al 2 o 3 Colloidal solution with HNO 3 Adjust the pH to 3.5, weigh 100g of the SiC annular carrier and dip it into the prepared colloidal solution, dry at 120°C for 24h, then calcinate at 300°C for 8h and cool to room temperature for use. PdCl containing 0.02g Pd 2 solution, AgNO containing 0.1 g Ag 3 solution, containing 0.1g Bi in Bi(NO 3 ) 2 solution, Ca(NO 3 ) 2 Step-by-step impregnation of the carrier to be used, each element should be dried at 150°C for 24 hours, and finally calcined at 600°C for 8 hours to obtain catalyst A, in which the content of Pd is 0.03%, the content of Ag is 0.1%, and the content of Bi is 0.1 %, the Ca content is 0.01%.

Embodiment 2

[0029] Containing 10g Al 2 o 3 5% Al 2 o 3 In the colloidal solution, add HNO 3Adjust the pH to 2.5, weigh 100 g of the SiC annular carrier to impregnate, dry at 200° C. for 8 hours, calcinate at 300° C. for 15 hours, and then cool to room temperature for use. The carrier to be used was first impregnated in a nitrate solution containing 0.01g Ag, 0.05g Bi, 0.02g La, dried at 200°C for 8h, and then the carrier was impregnated in a solution containing 0.05g Pd, 0.005g Ca, 0.005g Sr And in the chloride salt solution of 0.02g K, drying at 200°C for 8h, calcining at 300°C for 15h to obtain catalyst B, wherein the content of Pd is 0.05%, the content of Ag is 0.01%, the content of Bi is 0.05%, and the content of Ca is 0.005%, The K content is 0.02%, the Sr content is 0.005%, and the La content is 0.02%.

Embodiment 3

[0031] Containing 6g Al 2 o 3 30% Al 2 o 3 Colloidal solution, with HNO 3 Adjust the pH to 4.2, weigh 100g of talcum powder ring carrier and dip it into the prepared solution, dry at 100°C for 13.5h, then calcinate at 780°C for 20h, then cool to room temperature for use. Then Pd(NO) containing 0.01gPd 3 ) 2 , AgNO with 0.5 g Ag 3 , Bi(NO 3 ) 2 , Cu(NO 3 ) 2 , NaNO with 0.05g Na 3 Prepare a mixed solution, impregnate the carrier to be used in the mixed solution, dry at 135° C. for 30 hours, and then calcinate at 550° C. for 20 hours to obtain catalyst C. Wherein the Pd content is 0.01%, the Ag content is 0.5%, the Bi content is 0.5%, the Cu content is 0.05%, and the Na content is 0.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com