Process for suspended hydrogenating of anthraquinone compound

A compound and process technology, applied in the directions of peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, inorganic chemistry, chemical instruments and methods, etc., which can solve the problem of low separation efficiency between catalysts and working fluids , not optimization and other issues, to achieve the effect of high catalyst utilization, uniform distribution, and rapid heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

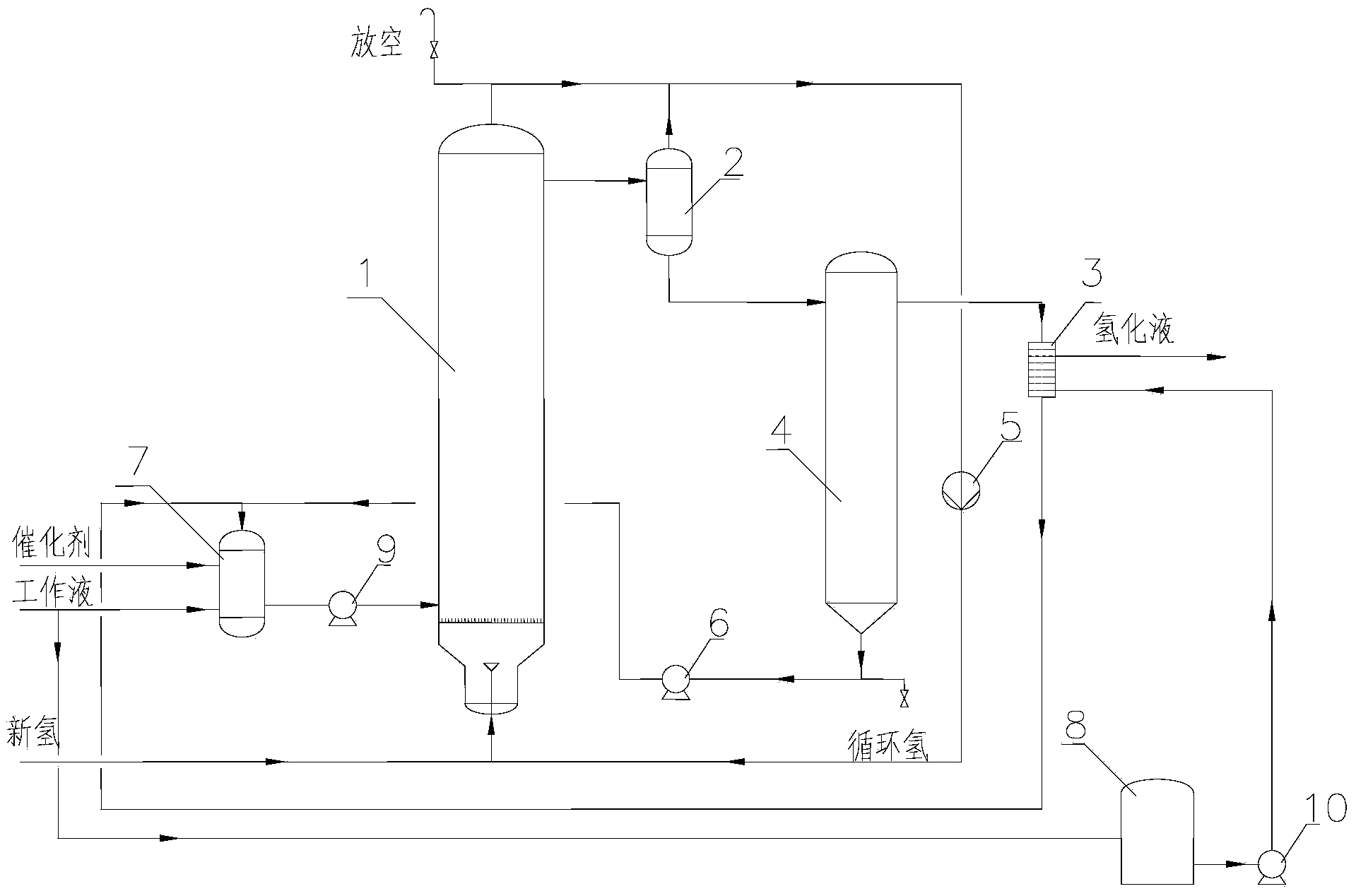

[0027] The evaluation device is a small full-process hydrogen peroxide production device, and the hydrogenation process is a suspended bed anthraquinone hydrogenation process. figure 1 Shown. The size of the suspended bed hydrogenation tower is φ200×3000mm, and the size of the sedimentation bed is φ150×2000mm. The catalyst is alumina microspheres supporting active metal palladium. The average particle size of the catalyst is 150μm, the palladium loading is 1%, and the working fluid system is heavy aromatic hydrocarbon + trioctyl phosphate + 2-ethylanthraquinone + tetrahydro2- Ethyl anthraquinone, in which the volume ratio of heavy aromatics to trioctyl phosphate is 3:1, the mass ratio of 2-ethylanthraquinone to tetrahydro-2-ethylanthraquinone is 1:1, and the effective anthraquinone concentration is 120g / L, the concentration of the catalyst in the working fluid is 0.5wt%. Hydrogenation reaction process conditions: hydrogenation reaction temperature 60℃, hydrogenation tower top...

Embodiment 2

[0029] The evaluation device is a small-scale full-process hydrogen peroxide production device, and the hydrogenation process is a suspended bed anthraquinone hydrogenation process as shown in the figure. The size of the suspended bed hydrogenation tower is φ100×5000mm, and the size of the sedimentation bed is φ150×4000mm. The catalyst is a silica microsphere supported active metal palladium catalyst, the average particle size of the catalyst is 100μm, the palladium loading is 1%, and the working fluid system is heavy aromatics + tetrabutylurea + 2-ethylanthraquinone + tetrahydro 2 -Ethylanthraquinone, where the volume ratio of heavy aromatics to tetrabutylurea is 1:1, the mass ratio of 2-ethylanthraquinone to tetrahydro-2-ethylanthraquinone is 3:1, and the effective anthraquinone concentration It is 120g / L, and the concentration of the catalyst in the working fluid is 0.5wt%. Hydrogenation reaction process conditions: the hydrogenation reaction temperature is 50℃, the reactio...

Embodiment 3

[0031] The evaluation device is a small-scale full-process hydrogen peroxide production device, and the hydrogenation process is a suspended bed anthraquinone hydrogenation process as shown in the attached drawing. The size of the suspended bed hydrogenation tower is φ500×15000mm, and the size of the sedimentation bed is φ100×3000mm. The catalyst is a catalyst with alumina microspheres supporting active metal platinum, the average particle size of the catalyst is 180μm, the palladium loading is 0.5%, and the working fluid system is heavy aromatic hydrocarbon + trioctyl phosphate + 2-ethylanthraquinone + tetrahydro2- Ethyl anthraquinone, in which the volume ratio of heavy aromatics to trioctyl phosphate is 3:1, the mass ratio of 2-ethylanthraquinone to tetrahydro-2-ethylanthraquinone is 1:1, and the effective anthraquinone concentration is 120g / L, the concentration of the catalyst in the working fluid is 0.5wt%. Hydrogenation reaction process conditions: hydrogenation reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com