Method for preparing black titanium dioxide through auxiliary hydrogenation of hydrogen plasma

A technology of black titanium dioxide and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of narrow photoresponse range of titanium dioxide materials, difficulty in industrialization, complex process, etc., achieve remarkable reduction effect, controllable particle size, The effect of high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Use commercial titanium dioxide (P25) as raw material, put it into a closed tube furnace, vacuumize the whole system to 0.1Pa, and then inject H into the system 2 After 10 minutes, exhaust the remaining oxygen in the system. After heating the sample to 500°C, continue to feed hydrogen and adjust the gas flow to keep the system pressure at 100Pa, then turn on the RF power to start the plasma, and slowly increase the power to 200W. After 8 hours of reaction, turn off the radio frequency power supply and the heating power supply in turn, and after the sample cools down, turn off the gas flow.

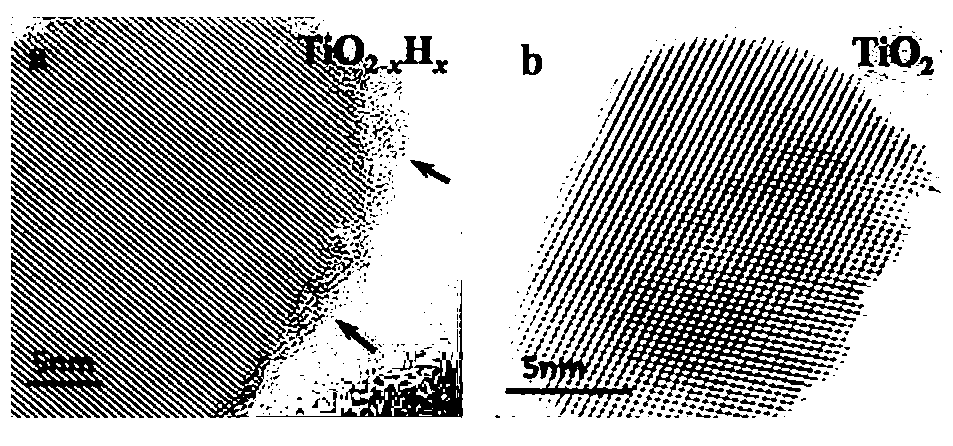

[0045] TEM images of the treated samples as figure 2 As shown, it can be seen that after the hydrogenation is completed, an amorphous layer with a thickness of about 2 nm is formed on the surface of the sample.

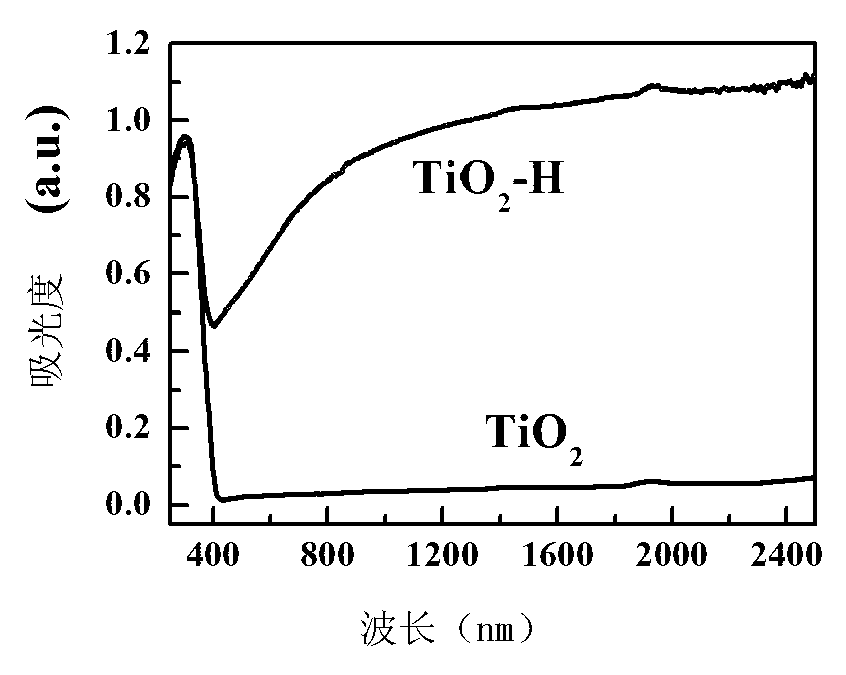

[0046] After hydrogenation treatment, the sample changed from white to black, and the absorption spectrum was as follows: image 3 As shown, the absorption of the sampl...

Embodiment 2

[0052] Titanium dioxide microspheres made by hydrothermal method were used as raw materials (Lü, X.; Ding, S.; Xie, Y.; Huang F.; Eur.J.Inorg.Chem., 2011, 2879-2883), and put into a closed In the tube furnace, after the whole system is evacuated to 0.1Pa, Ar / H is introduced into the system 2 Mixed gas (molar ratio 1:1) for 10 minutes, exhaust the remaining oxygen in the system. After heating the sample to 300°C, continue to feed Ar / H into the system 2 Mix the gas and adjust the gas flow to keep the system pressure at 100Pa, then turn on the RF power to start the plasma, and slowly increase the power to 200W. After 12 hours of reaction, turn off the radio frequency power supply and the heating power supply in turn, and after the sample cools down, turn off the gas flow.

[0053] After hydrogenation treatment, the sample changes from white to black, and the absorption spectrum test shows that the absorption of the treated sample in the visible and infrared regions increases si...

Embodiment 3

[0057] Use commercial titanium dioxide (P25) as raw material, put it into a closed tube furnace, vacuumize the whole system to 0.1Pa, and then inject H into the system 2 After 10 minutes, exhaust the remaining oxygen in the system. After heating the sample to 500°C, continue to feed hydrogen into the system and adjust the gas flow to keep the system pressure at 100Pa, then turn on the RF power to start the plasma, and slowly increase the power to 200W. After 4 hours of reaction, turn off the radio frequency power supply and the heating power supply in turn, and after the sample cools down, turn off the gas flow.

[0058] After hydrogenation treatment, the sample changed from white to black. After the treatment, the absorption of the sample in the visible and infrared regions increased significantly. It can be calculated that the absorption of the sample in the visible region (400-760nm) and infrared region (>760nm) accounted for the entire 22% and 20% of the solar spectrum. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com