Anthraquinone functional cellulose membrane and preparation method thereof

A cellulose membrane, functionalized technology, applied in the fields of material engineering and environmental engineering, chemical engineering, can solve the problems of low content of anthraquinone group, low degree of reaction, affecting the treatment of nitrogen-containing wastewater, etc., to achieve high grafting rate , low cost, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

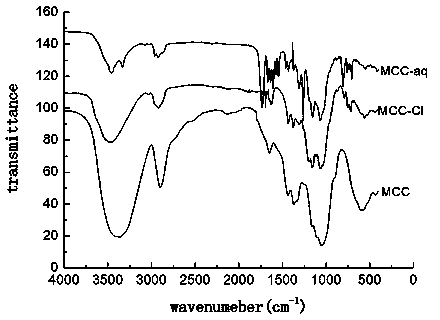

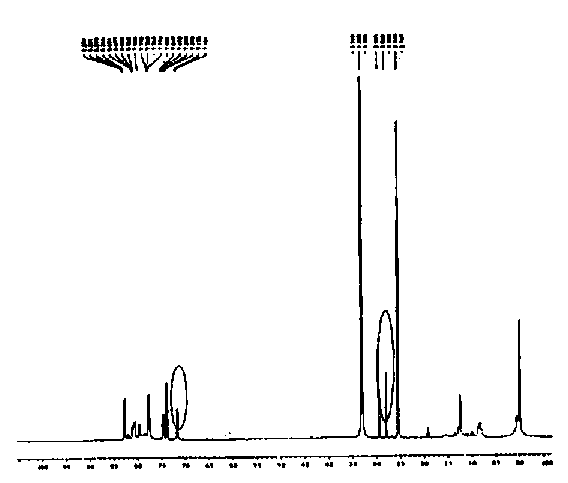

[0032] Put 10g of microcrystalline cellulose and 100g of [Amim]Cl into a four-neck flask, raise the temperature to 80°C and keep it warm for 2h, wait for the cellulose to dissolve and cool to room temperature, then add 100g of a pre-prepared 50% thionyl chloride / DMF solution, Raise the temperature to 80°C, stir with magnetic force for 4 hours, cool naturally after the reaction, add distilled water to precipitate the precipitate, filter and wash with water to obtain a light brown solid, dry it in vacuum at 30°C to obtain cellulose chloride, and measure the degree of substitution of the chlorinated cellulose is 1.89;

[0033] Pre-configure 20% NaOH aqueous solution for use. Weigh 10g of the prepared chlorinated cellulose and 200g of DMF into a four-neck flask to dissolve the cellulose, add 1g of NaOH aqueous solution, and finally put in 20g of 1-aminoanthraquinone, heat the oil bath to 100°C, and react with magnetic stirring for 6h. During the reaction Add pre-configured 20% Na...

Embodiment 2

[0039] In this example, ionic liquid [Bmim]Cl was used as a solvent to dissolve microcrystalline cellulose, and the subsequent chlorination process was the same as in Example 1, and the degree of substitution of the prepared chlorinated cellulose was 1.6;

[0040] Weigh 10g of the prepared chlorinated cellulose and 200g of DMF into a four-neck flask to dissolve the cellulose, add 1g of triethylamine, and finally put in 20g of 2-aminoanthraquinone, heat the oil bath to 100°C, and react with magnetic stirring for 6h. During the process, continue to drop triethylamine to keep the pH of the reaction system at 10-12. After the reaction, distilled water was added to precipitate a solid, which was filtered by suction and washed three times with ethanol at 40°C, and dried in vacuum at 30°C to obtain a red solid powder, which was anthraquinone functionalized cellulose. Branch rate is 65%;

[0041] The film-forming process of the prepared anthraquinone functionalized cellulose film mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com